Grabbing manipulator for carrier roller

A technology for grasping manipulators and robotic arms, which is applied to manipulators, assembly machines, metal processing equipment, etc., can solve the problems of high labor costs, high labor intensity, and low labor efficiency, so as to save labor costs, reduce labor intensity, reduce artificial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

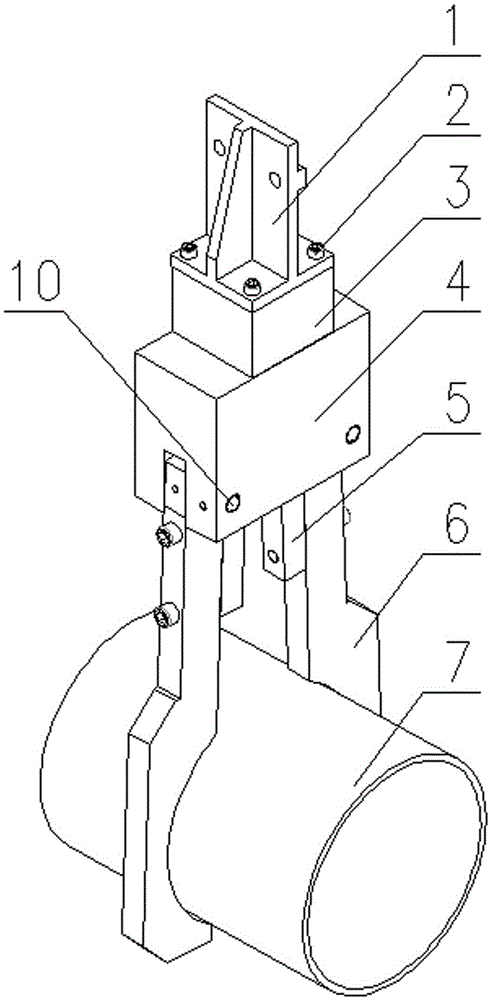

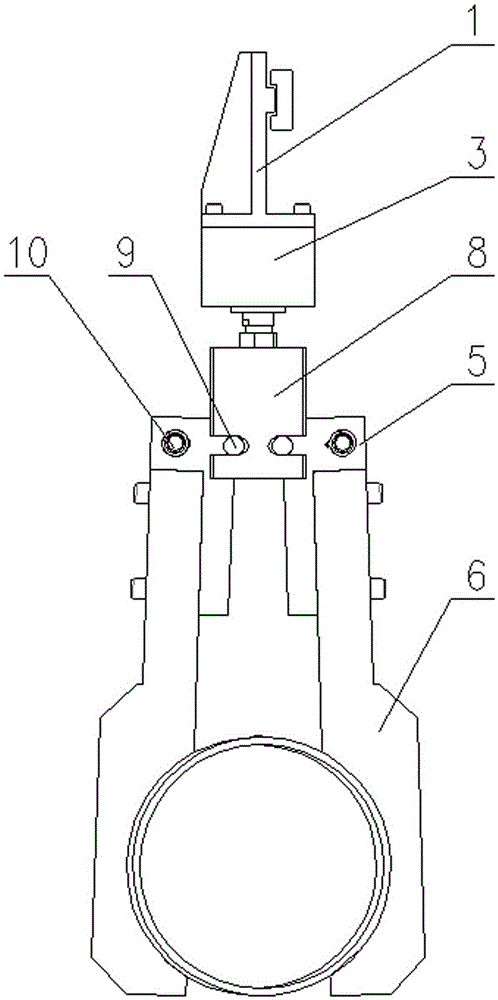

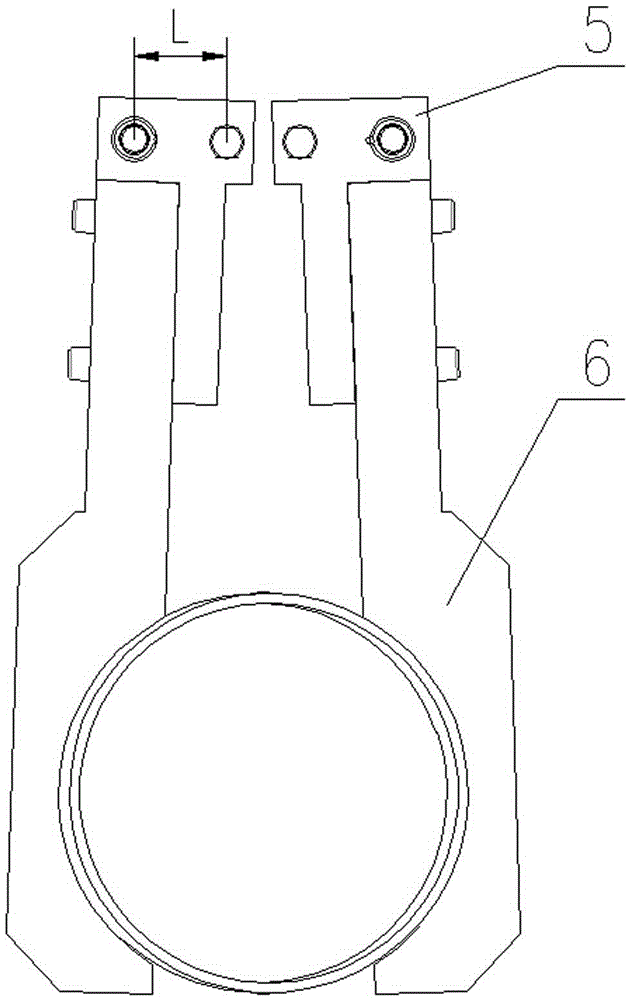

[0019] Such as figure 1 The shown idler grabbing manipulator includes a power cylinder 3 and two groups of grabbing mechanisms with symmetrical gaps. The structure of the grabbing mechanism is as follows: image 3 As shown, it includes a mechanical arm 5 and a mechanical finger 6 connected by the upper and lower structures. The roller grabbing robot also includes a mechanical arm pull block 8, and the outer cover of the mechanical arm pull block 8 is provided with an arm holder 4, and the arm holder The lower end of 4 is connected with the outer end of mechanical arm 5 through hinge shaft 10, and the upper end of arm fixed seat 4 is connected with the cylinder body of power cylinder 3 through screw 2 and fixed seat 1, and the top of mechanical arm pull block 8 is connected with the top of power cylinder 3. The output ends are connected to the piston rods; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com