Shock-resistant petroleum pipeline fixing base

A technology for oil pipelines and fixed bases, which is used in pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., and can solve problems such as non-adjustable height and base wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

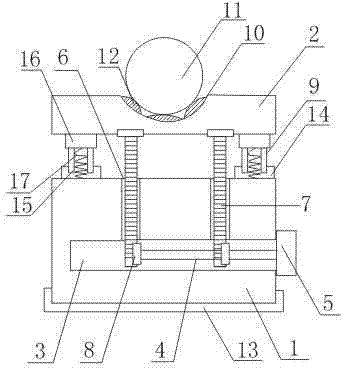

[0014] Example 1 as figure 1 As shown, an anti-seismic oil pipeline fixed base includes a base 1 and a support base 2 located above the base 1. A groove 3 is opened on the side wall of the base 1, and an adjusting screw 4 arranged in the groove 3 is also included. And the handle 5 connected with the adjustment screw 4, wherein the handle 5 is located on the side of the base 1, the upper surface of the base 1 has at least two holes 6, the lower end of the hole 6 communicates with the groove 3; 2 The rack 7 at the bottom, wherein the rack 7 is slidably set in the hole 6; it also includes a gear 8 fixed on the adjusting screw 4, wherein the gear 8 meshes with the rack on the rack 7; it also includes a gear set on the base 1 Elastic devices 9 on both sides of the upper surface, wherein one end of the elastic device 9 is connected to the upper surface of the base 1, and the other end is connected to the lower surface of the support seat 2; the upper surface of the support seat 2 ha...

Embodiment 2

[0017] On the basis of Embodiment 1, this embodiment also includes arcuate protrusions 12, which are made of elastic materials, and arcuate protrusions 12 are respectively arranged on the bottom and left and right sides of the semicircular groove 10. ; The oil pipeline 11 is in contact with the arc surface protrusion 12 .

[0018] The arc-shaped protrusion 12 provided in the semicircular groove 10 plays a role of supporting and fixing the oil pipeline 11 , so that the oil pipeline 11 can be placed in the semicircular groove 10 smoothly.

Embodiment 3

[0020] On the basis of embodiment 1 or embodiment 2, this embodiment further includes a rubber sleeve 13 sleeved on the lower end of the base 1 .

[0021] The rubber sleeve 13 sleeved on the lower end of the base 1 plays the role of shock resistance and buffering for the base 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com