Drying machine adopting freezing circulatory system

A circulation system and dryer technology, applied in the field of dryers, can solve the problems of long restart time of the compressor 31, shortened service life of the compressor 31, prolonged drying time, etc., so as to shorten the drying time and reduce the Refrigerant temperature, effect of preventing interruption of drying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

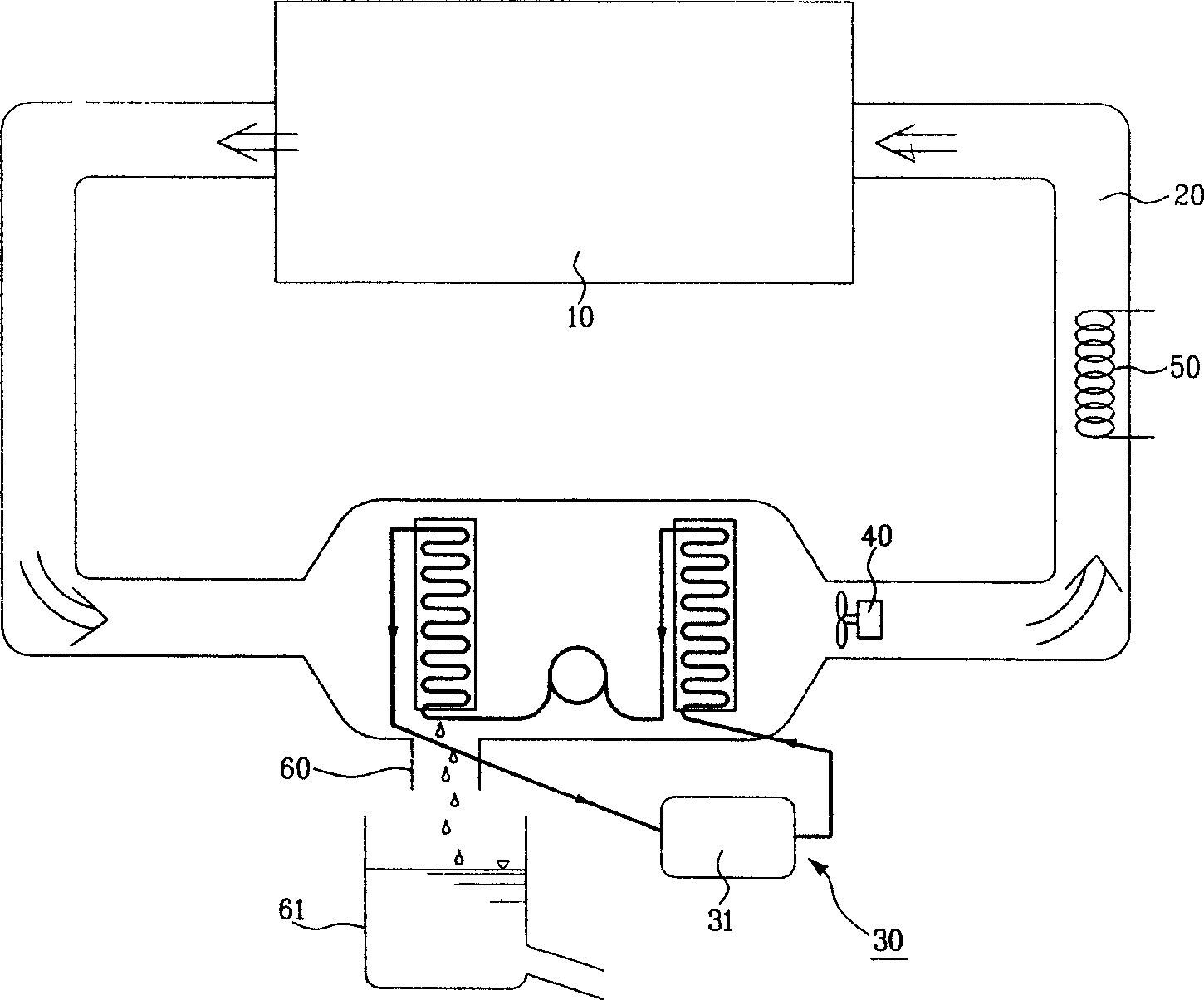

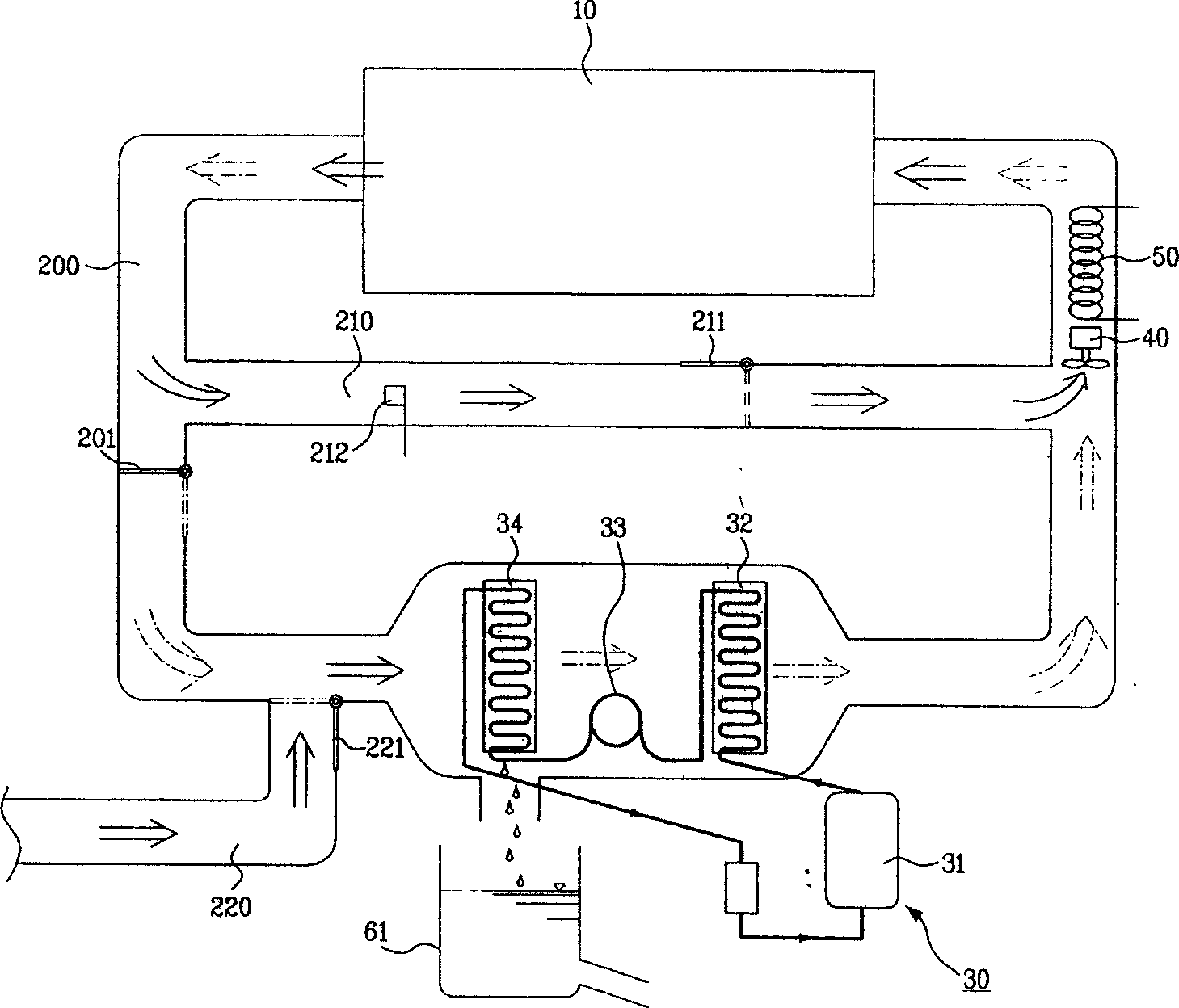

[0046] figure 2 It is a schematic diagram of the structure of the dryer adopting the refrigeration cycle system of the present invention. Such as figure 2As shown, the dryer adopting the refrigerating circulation system of the present invention includes: a drum 10, a circulation duct 200, a blowing fan 40, an electric heater 50, and a refrigerating circulation system 30; the inside of the drum 10 is used to hold objects to be dried And hot air flows in / out; the two ends of the circulation duct 200 are respectively connected with the air inlet and the exhaust port of the drum 10 to form a hot air circulation channel; the blowing fan 40 is arranged in the circulation duct 200 for use The electric heater 50 is arranged in the circulation duct 200 to heat the air; the refrigerating circulation system 30 is used to remove moisture in the air flowing out o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com