Low-emission type polypropylene material and preparation method and application thereof

A polypropylene material, low emission technology, applied in the field of modified plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

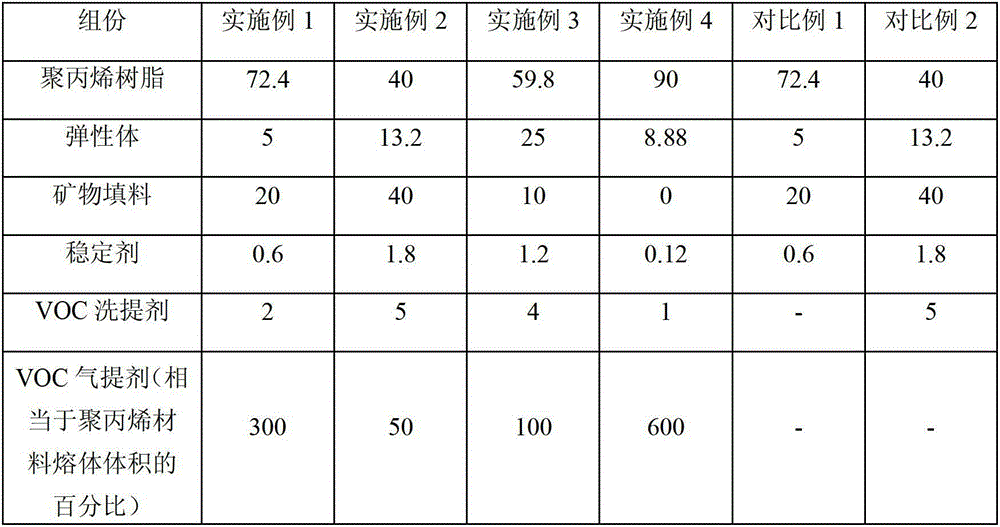

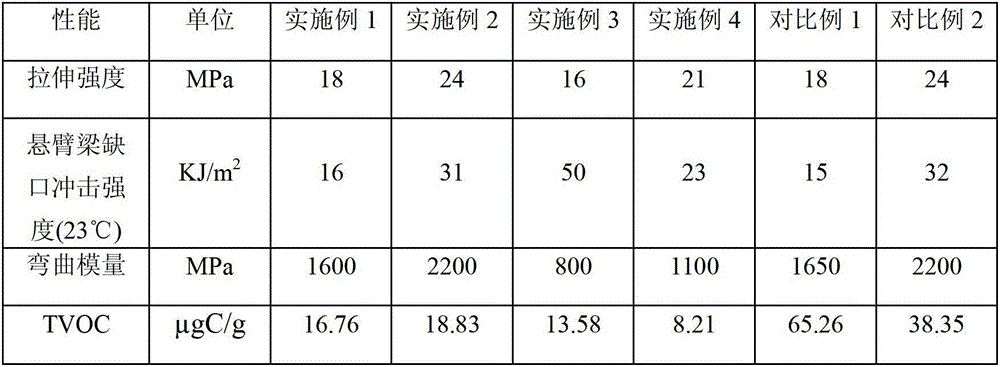

[0031] A kind of low emission type polypropylene material, its raw material formula is shown in Table 1, and its preparation method comprises the following steps:

[0032] Add polypropylene, elastomer, mineral filler, and stabilizer from the main feeding port of the twin-screw extruder for melt blending; atomize the VOC stripping agent, then fully mix with the VOC air stripping agent, add The side feeding port of the twin-screw extruder is melted and blended with other raw materials, and extruded and granulated by vacuum extrusion through the extruder to obtain the low-emission polypropylene material; the aspect ratio of the twin-screw extruder is (36-56): 1. The processing temperature of the twin-screw extruder is 180°C. VOC eluent atomization technology and extruder vacuum extraction both adopt conventional processes.

[0033] Among them, the polypropylene used is homopolypropylene, the elastomer is ethylene-butene copolymer, the VOC stripping agent is isopropanol, the mine...

Embodiment 2

[0035] A low-emission polypropylene material, its raw material formula is shown in Table 1, and its preparation method is the same as in Example 1, wherein the processing temperature of the twin-screw extruder is 210°C.

[0036] The mineral filler used is talcum powder, and the VOC stripping agent is N 2 , polypropylene is copolymerized polypropylene, elastomer is ethylene-propylene-diene copolymer, VOC eluting agent is n-hexanol. Stabilizer used is with embodiment 1.

Embodiment 3

[0038] A low-emission polypropylene material, its raw material formula is shown in Table 1, its preparation method is the same as that of Example 1, and the processing temperature of the twin-screw extruder is 230°C.

[0039] The mineral filler used is talcum powder, and the VOC stripping agent is N 2 , the polypropylene used is a mixture of homopolypropylene and copolymerized polypropylene in a mass ratio of 1:1, and the elastomer is composed of ethylene-butene copolymer and ethylene-octene copolymer in a mass ratio of 1:1 Mixture, VOC stripping agent is ethanol. Stabilizer used is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com