Device and method for vacuumizing in membrane of soft packaged battery

A soft-pack battery and vacuum technology, which is applied in battery assembly, secondary battery manufacturing, battery pack components, etc., can solve the problems affecting battery performance and yield, battery bulging, and sealing difficulties, and achieves simple and easy structure. The effect of using and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

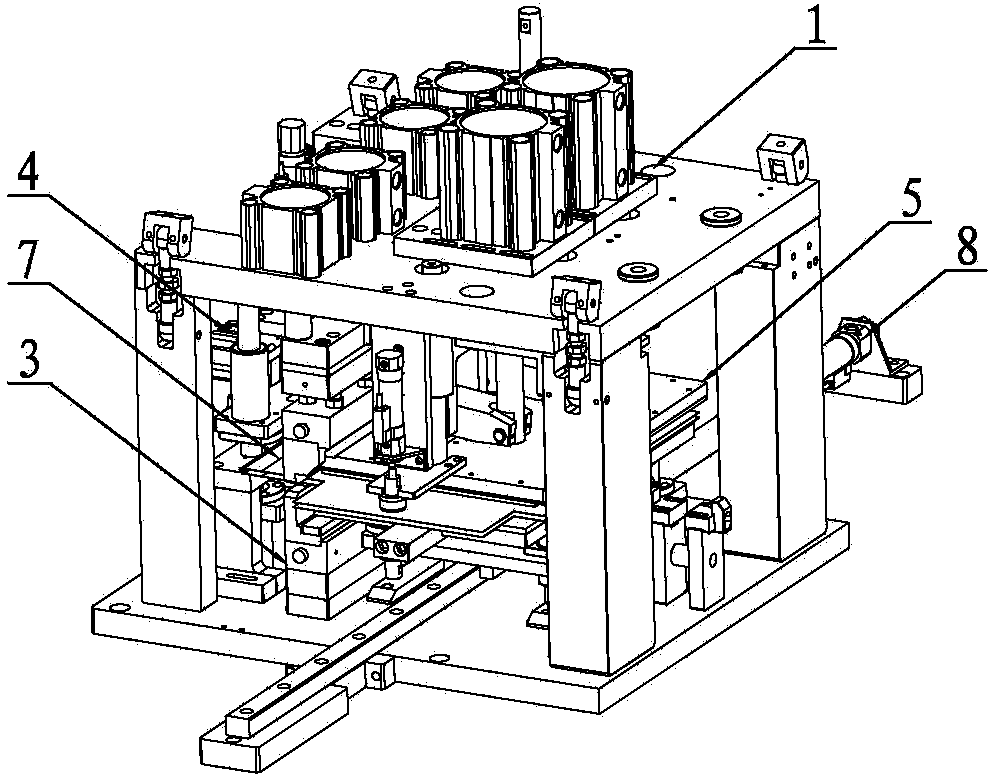

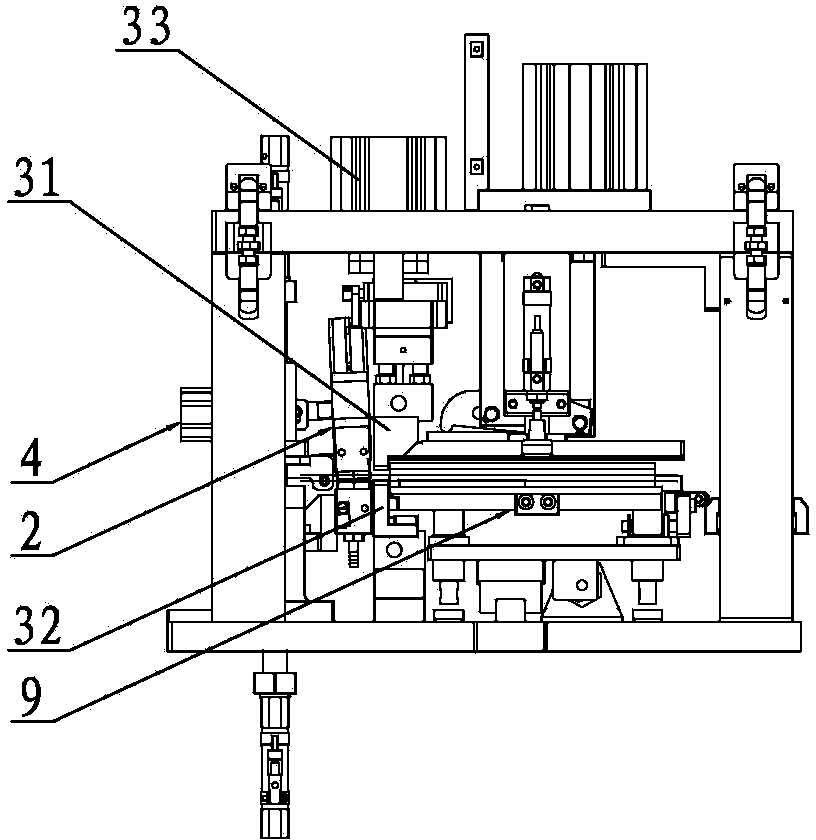

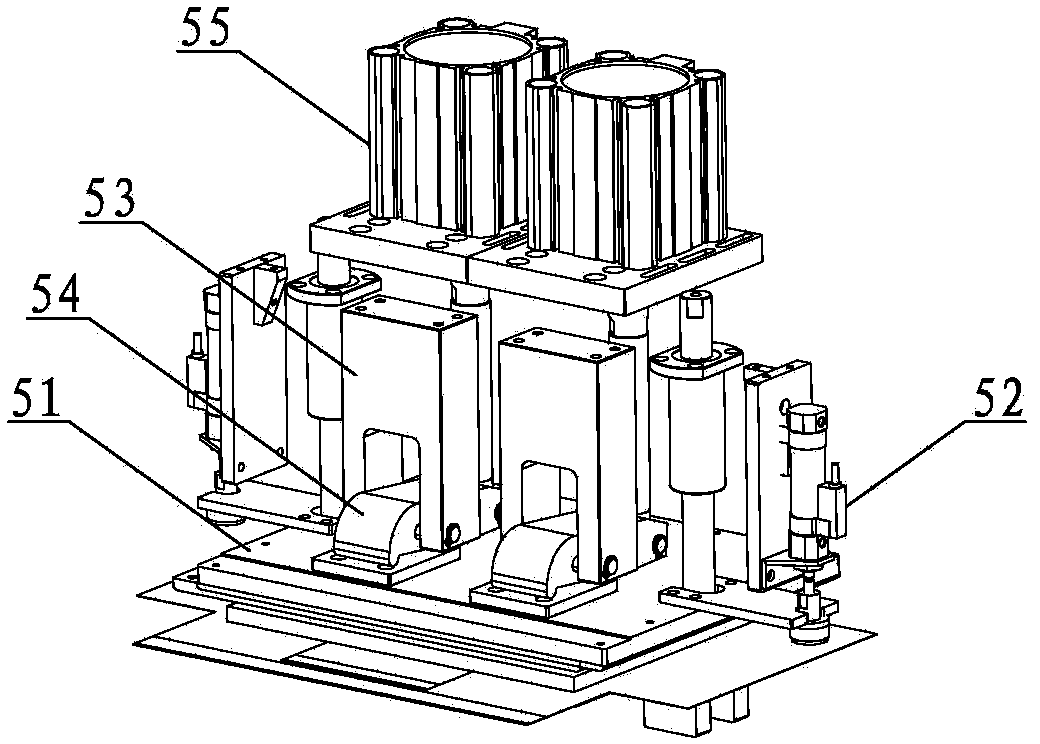

[0032] see Figure 1 to Figure 6 , a vacuum pumping device for a pouch battery, comprising a fixed frame 1, the fixed frame 1 is provided with a vacuum clamping mechanism 2 for clamping an air bag 7 of the battery and a positioning table 9 for placing the battery, the The vacuum clamping mechanism 2 includes a first abutting seat 21 arranged above the airbag bag 7 of the battery and a second abutting seat 22 arranged below the airbag bag 7 of the battery. The first abutting seat 21 is provided with an annular The upper suction cup 23 and the first cylinder 28 for driving the annular upper suction cup 23 to move up and down, the second abutting seat 22 is provided with an annular lower suction cup 24, and the annular upper suction cup 23 and the annular lower suction cup 24 are combined to draw a vacuum The airbag bag 7 is closely attached to the annular upper suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com