Low-emission, low-odor automobile composite polypropylene material

A technology for composite polypropylene and foamed polypropylene, which is applied in the direction of silicon compounds, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problem of increasing the content of ketones in composite materials, without considering the precipitation on the surface of glass fibers and Residual small molecular substances, volatiles cannot be completely removed at the same time, etc., to achieve the effect of reducing the generation of small molecules, high filling, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

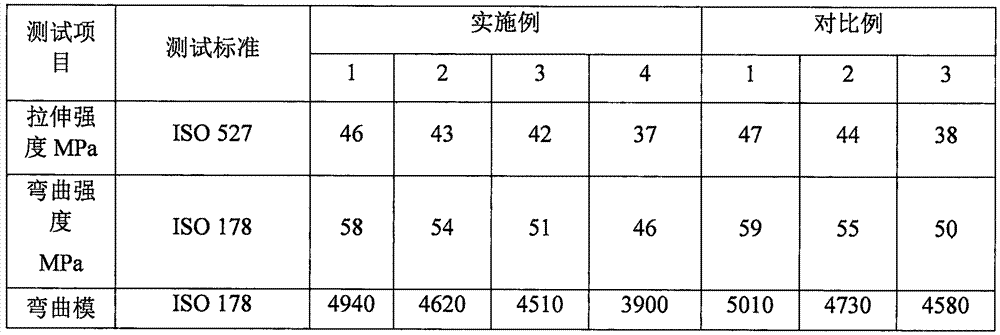

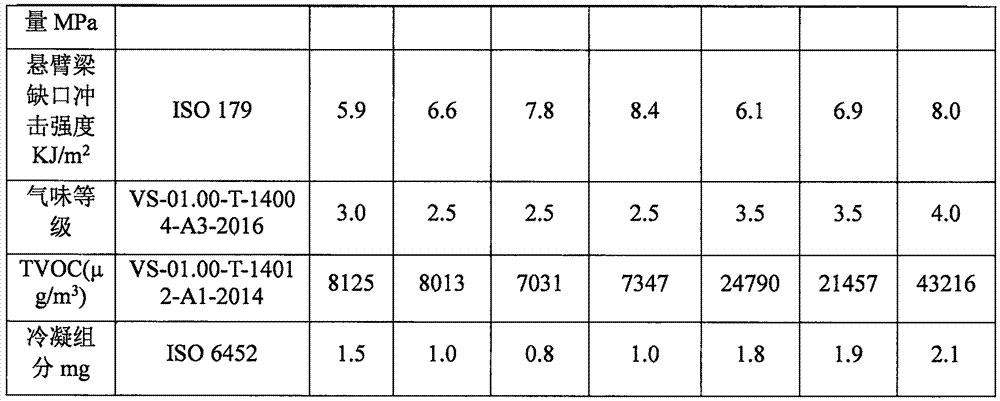

Embodiment 1

[0040]A low-emission, low-odor composite polypropylene material for automobiles, consisting of the following mass percentages:

[0041] Polypropylene: 55%, odor emitting adsorbent: 1%, inorganic filler: 34%, toughening agent: 5%, compatibilizer: 4%, antioxidant: 0.8%, anti-UV agent: 0.2%;

[0042] The adsorbent is prepared according to the mass ratio of self-made inorganic porous adsorption material and foamed polypropylene stripping agent in a ratio of 1:1.

Embodiment 2

[0044] A low-emission, low-odor composite polypropylene material for automobiles, consisting of the following mass percentages:

[0045] Polypropylene: 58.5%, odor emitting adsorbent: 1.5%, inorganic filler: 30%, toughening agent: 5%, compatibilizer: 3%, antioxidant: 0.8%, anti-UV agent: 0.2%;

[0046] The adsorbent is prepared according to the mass ratio of self-made inorganic porous adsorption material and foamed polypropylene stripping agent in a ratio of 1:1.5.

Embodiment 3

[0048] A low-emission, low-odor composite polypropylene material for automobiles, consisting of the following mass percentages:

[0049] Polypropylene: 64%, odor emitting adsorbent: 2%, inorganic filler: 25%, toughening agent: 5%, compatibilizer: 3%, antioxidant: 0.8%, anti-UV agent: 0.2%;

[0050] The adsorbent is prepared according to the mass ratio of self-made inorganic porous adsorption material and foamed polypropylene stripping agent in a ratio of 1:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com