Preparation method for nanometer reinforced modified thermoplastic resin material

A thermoplastic resin and nano-reinforced technology, applied in the production of bulk chemicals, etc., can solve problems such as nano-dispersion and performance defects of modified materials, and achieve the effects of solving agglomeration, improving comprehensive performance, and having a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

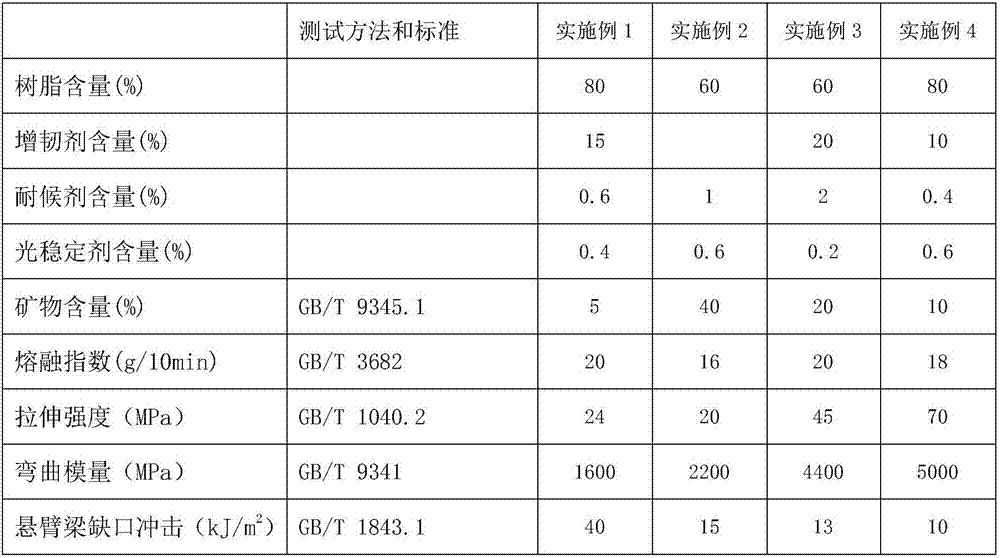

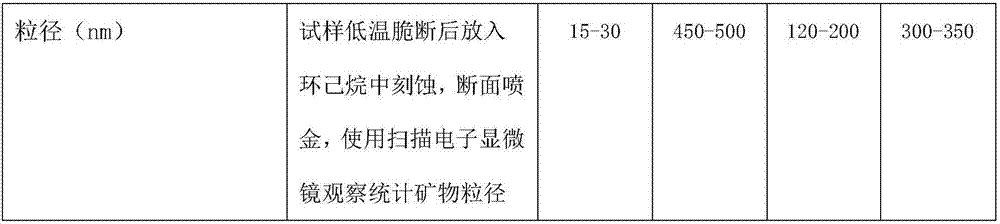

Embodiment 1

[0029] The nano-hectorite reinforced polypropylene material (PP) with a particle size of 10nm, the specific preparation method and production process are as follows:

[0030] (1) Mineral gel preparation: add 0.5% water-soluble silicone oil to pure water, then weigh nano-hectorite and water at a weight ratio of 10:1, disperse at a high speed for 5 minutes and leave to stand to make a mineral gel;

[0031] (2) Preparation of premix: Weigh polypropylene resin, toughening agent, weathering agent and lubricant in the mixer according to the ratio in Table 1, mix for 2 minutes, and the rotating speed is 300 rpm; then add the prepared mineral The gel is mixed again for 4 minutes, wherein the amount of mineral gel required can be converted and weighed according to the mineral content during preparation;

[0032] (3) Preparation of nano-reinforced materials: the premix is melted, extruded and granulated in the twelve-section parallel twin-screw extruder, and the supercritical carbon d...

Embodiment 2

[0034] Nano hydromica reinforced polyethylene material with a particle size of 400nm, the specific preparation method and production process are as follows:

[0035] (1) Mineral gel preparation: add 0.7% water-soluble silicone oil to pure water, then weigh nano-water mica and water at a weight ratio of 15:1, disperse at high speed for 7 minutes, and leave to stand to make mineral gel;

[0036] (2) Premix preparation: Take polyethylene resin, toughening agent, weathering agent and lubricant in the mixer according to the design ratio in Table 1, mix for 3 minutes, and the rotating speed is 400 rpm; then add the prepared mineral The gel is mixed again for 5 minutes, wherein the amount of mineral gel required can be converted and weighed according to the mineral content during preparation;

[0037] (3) Preparation of nano-reinforced material: the premix is melted, extruded and granulated in a twelve-section parallel twin-screw extruder, and supercritical carbon dioxide fluid is ...

Embodiment 3

[0039] The nano sepiolite reinforced acrylonitrile-butadiene-styrene copolymer (ABS) material with a particle size of 100nm, the specific preparation method and production process are as follows:

[0040] (1) Mineral gel preparation: add 1.0% water-soluble silicone oil to pure water, then weigh nano sepiolite and water at a weight ratio of 20:1, disperse at a high speed for 7 minutes and leave to stand to make a mineral gel;

[0041] (2) Preparation of premix: Weigh acrylonitrile-butadiene-styrene copolymer resin, toughening agent, weather resistance agent and lubricant in the mixer according to the design ratio in Table 1, and mix for 4 minutes at a speed of 500 rev / min; then add the prepared mineral gel and mix again for 6 minutes, wherein the required amount of mineral gel can be converted and weighed according to the mineral content during preparation;

[0042] (3) Preparation of nano-reinforced material: the premix is melted, extruded and granulated in a twelve-section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com