Coated low-temperature flue gas denitration catalyst, and preparation method and application thereof

A denitrification catalyst and low-temperature flue gas technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of NOx conversion rate decline, achieve good coating firmness, large specific surface area, and preparation Simple and reasonable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

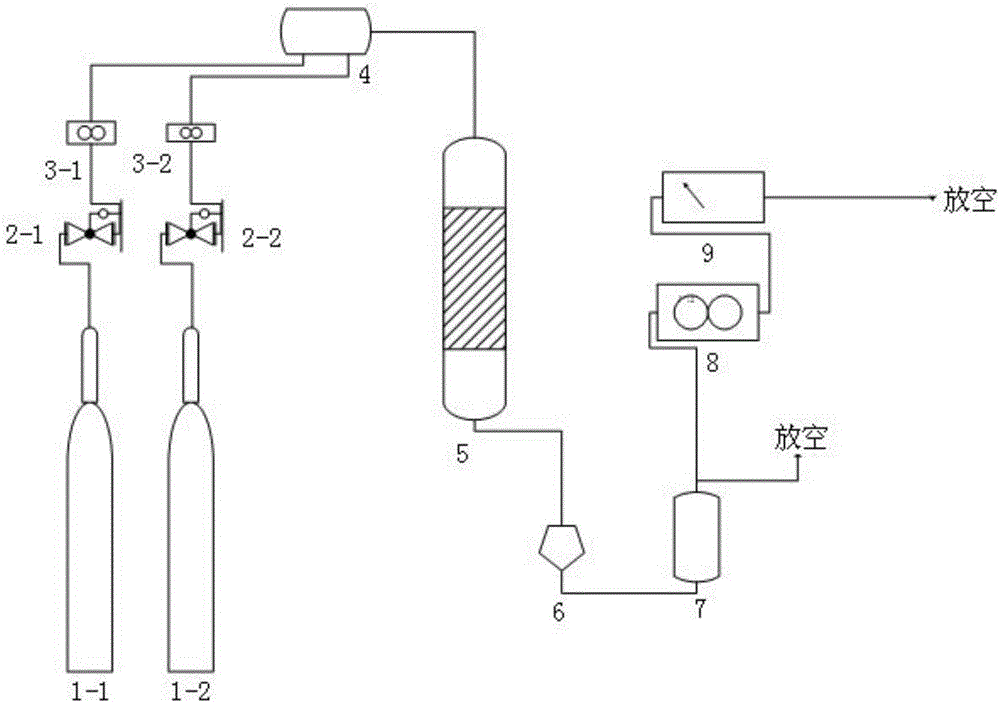

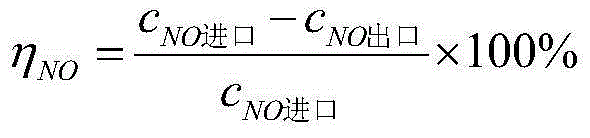

Method used

Image

Examples

example 1

[0045] Immerse 100g of commercial cordierite honeycomb ceramics with a pore size of 5 mesh in 150mL of 2mol / L nitric acid solution for pretreatment, take it out after immersion for 1.5h, and then wash it with 300mL deionized water for 4 times until the washing liquid becomes neutral. Dry in an oven for 8 hours to obtain modified cordierite honeycomb ceramics.

[0046] 200g of TiOSO 4 Add 1 L of sulfuric acid solution with a mass concentration of 3.5%, and heat and stir in a water bath at 45° C. for 2 hours to prepare a titanyl sulfate solution. After filtering the titanyl sulfate solution, a clear 200 g / L titanyl sulfate solution was obtained. 2mol / L K 2 CO 3 The solution was slowly added into the titanyl sulfate solution above, the dropping rate was 1 mL / min and the pH at the end of the dropping was 2-2.5. 2ml of Tween 80 was added to the obtained suspension as a dispersant, and stirred at a constant speed for 4h. The resulting suspension was washed with deionized water ...

example 2

[0052] Using the method in Example 1, the cordierite honeycomb ceramics were first modified and pretreated to prepare titanium dioxide powder.

[0053] A certain amount of deionized water was added into the three-necked flask, and the deionized water in the three-necked flask was heated to 88°C. Under the condition of magnetic stirring, add ultra-high-purity pseudo-boehmite-type aluminum hydroxide (SB powder) evenly into the deionized water, wait for the SB powder and deionized water to form a suspension of a certain concentration, reflux and stir for 2 hours, and then follow the Add 2mol / L nitric acid in a certain proportion, wherein the concentration ratio of SB powder and nitric acid is c(H + ) / c(AlOOH)=0.2; then add polyethylene glycol 400 (PEG400) with a mass concentration of 5%, so that the SB powder is fully peptized, and finally the colloid is aged for 7 hours under reflux conditions at 100°C to form a mass concentration of 12% stabilized aluminum sol.

[0054] With ...

example 3

[0058] Using the method in Example 1, the cordierite honeycomb ceramics were first modified and pretreated to prepare titanium dioxide powder.

[0059] A certain amount of deionized water was added into the three-necked flask, and the deionized water in the three-necked flask was heated to 82°C. Under the condition of magnetic stirring, add ultra-high-purity pseudo-boehmite-type aluminum hydroxide (SB powder) evenly into the deionized water, wait for the SB powder and deionized water to form a suspension with a certain concentration, reflux and stir for 3 hours, and then follow the Add 3mol / L nitric acid in a certain proportion, wherein the concentration ratio of SB powder and nitric acid is c(H + ) / c(AlOOH)=0.1; then add polyethylene glycol 400 (PEG400) with a mass concentration of 6%, to make the SB powder fully peptized, and finally make the colloid age under reflux conditions at 85°C for 8h to form a mass concentration of 10% stabilized aluminum sol.

[0060] With Mn(CH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com