Method and device for preparing microparticles by splitting liquid drop using electric charge oscillation method

An oscillation method and micro-particle technology, which is applied in the field of micro-particle preparation, can solve the problems of nozzle blockage and instability, and achieve the effects of reducing equipment investment, good product quality and short process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

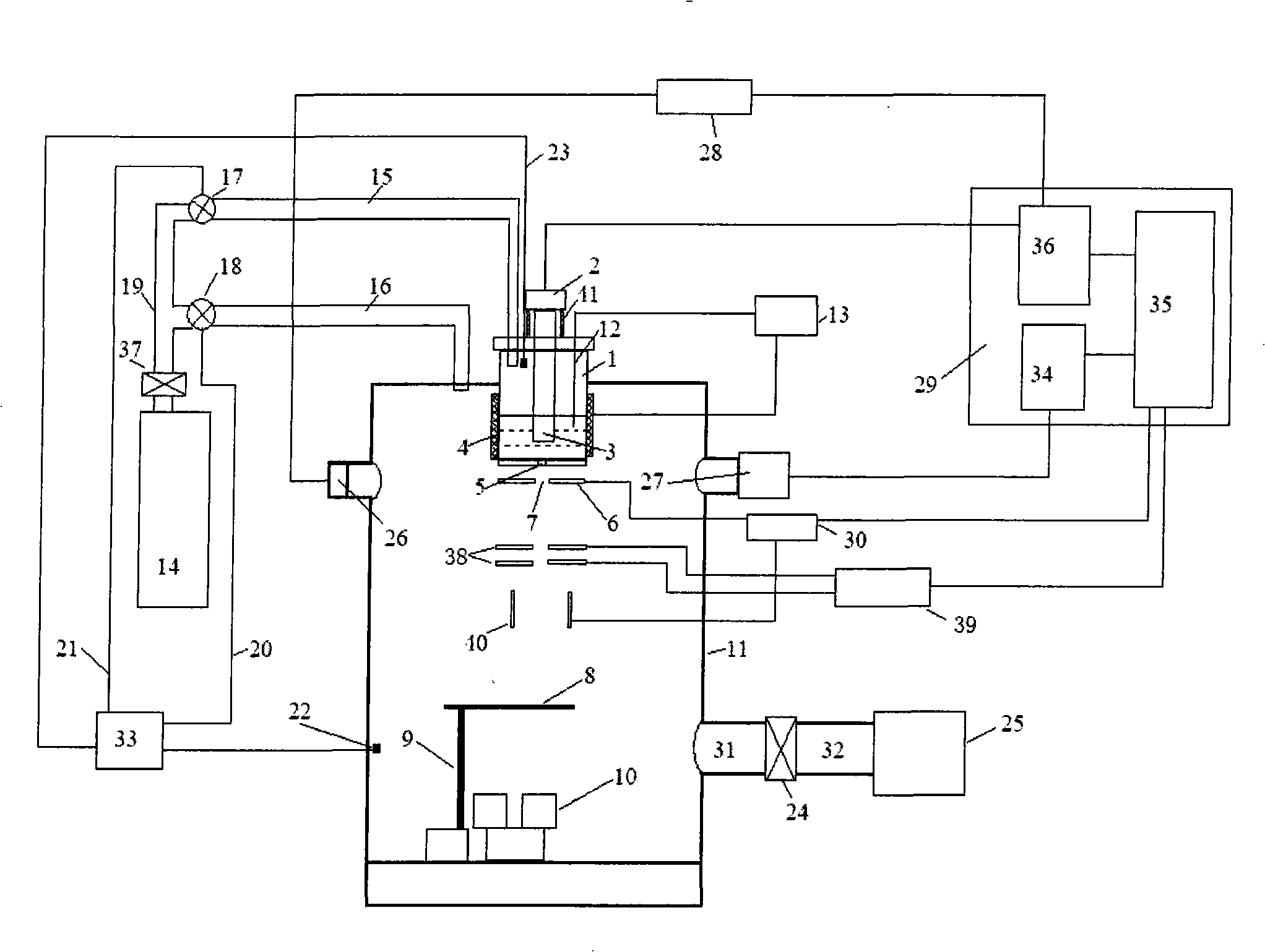

Image

Examples

Embodiment 1

[0034] (1) Open the upper cover of the crucible, add 100g of the metal material Sn-3.5Ag-0.5Cu to be smelted into the crucible, and seal it; (2) Add the cooling liquid to the collector, and move the baffle to the top of the collector , and seal the vacuum chamber; (3) evacuate the crucible and the vacuum chamber, and fill it with nitrogen; (4) heat the crucible, melt the metal material in the crucible, and keep the temperature for 20 minutes after reaching 260 ° C; ( 5) Turn on the piezoelectric oscillator so that its frequency is 6KH Z , apply a voltage of 250V to the electrode plate, and use the pressure control system to achieve a stable pressure difference of 0.5P between the crucible and the vacuum chamber 0 , so that the molten metal is ejected from the nozzle at the bottom of the crucible in the form of a laminar jet. Under the action of the vibrating head of the piezoelectric oscillator, the outflowing metal jet breaks into uniform droplets. When passing through the ga...

Embodiment 2

[0036] (1) Open the crucible upper cover, add the metal material Sn-37%Pb 100g that needs melting in the crucible, and seal; Seal the vacuum chamber; (3) evacuate the crucible and the vacuum chamber, and fill it with nitrogen; (4) heat the crucible, melt the metal material in the crucible, and keep it warm for 25 minutes after the temperature reaches 250 ° C; (5) Turn on the piezoelectric oscillator so that its frequency is 10KH Z , apply a voltage of 200V to the electrode plate, and use the pressure control system to achieve a stable pressure difference of 1.5P between the crucible and the vacuum chamber 0 , so that the molten metal is ejected from the nozzle at the bottom of the crucible in the form of a laminar jet. Under the action of the vibrating head of the piezoelectric oscillator, the outflowing metal jet breaks into uniform droplets. When passing through the gap in the middle of the electrode plate, each Each droplet has an equal charge, the distance between the noz...

Embodiment 3

[0038] (1) Open the upper cover of the crucible, add 100g of metal material Sn-9Zn to be smelted into the crucible, and seal it; (2) Add the cooling liquid to the collector, move the baffle to the top of the collector, and seal the vacuum chamber; (3) evacuate the crucible and the vacuum chamber, and fill it with nitrogen; (4) heat the crucible, melt the metal material in the crucible, and keep it warm for 30 minutes after the temperature reaches 250 ° C; (5) open the pressure Electric oscillator makes its frequency 14.2KH Z , add a voltage of 300V to the electrode plate, and use the pressure control system to achieve a stable pressure difference of 1P between the crucible and the vacuum chamber 0 , so that the molten metal is ejected from the nozzle at the bottom of the crucible in the form of a laminar jet. Under the action of the vibrating head of the piezoelectric oscillator, the outflowing metal jet breaks into uniform droplets. When passing through the gap in the middle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com