Transformer paper oil insulation multi-factor combined aging test device and life prediction method thereof

A technology of transformer oil and aging test, applied in the direction of measuring devices, instruments, measuring electricity, etc., can solve the problems of transformer operating environment differences, complex device structure, complicated steps, etc., and achieve the advantages of simple operation, uniform test conditions, and improved accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

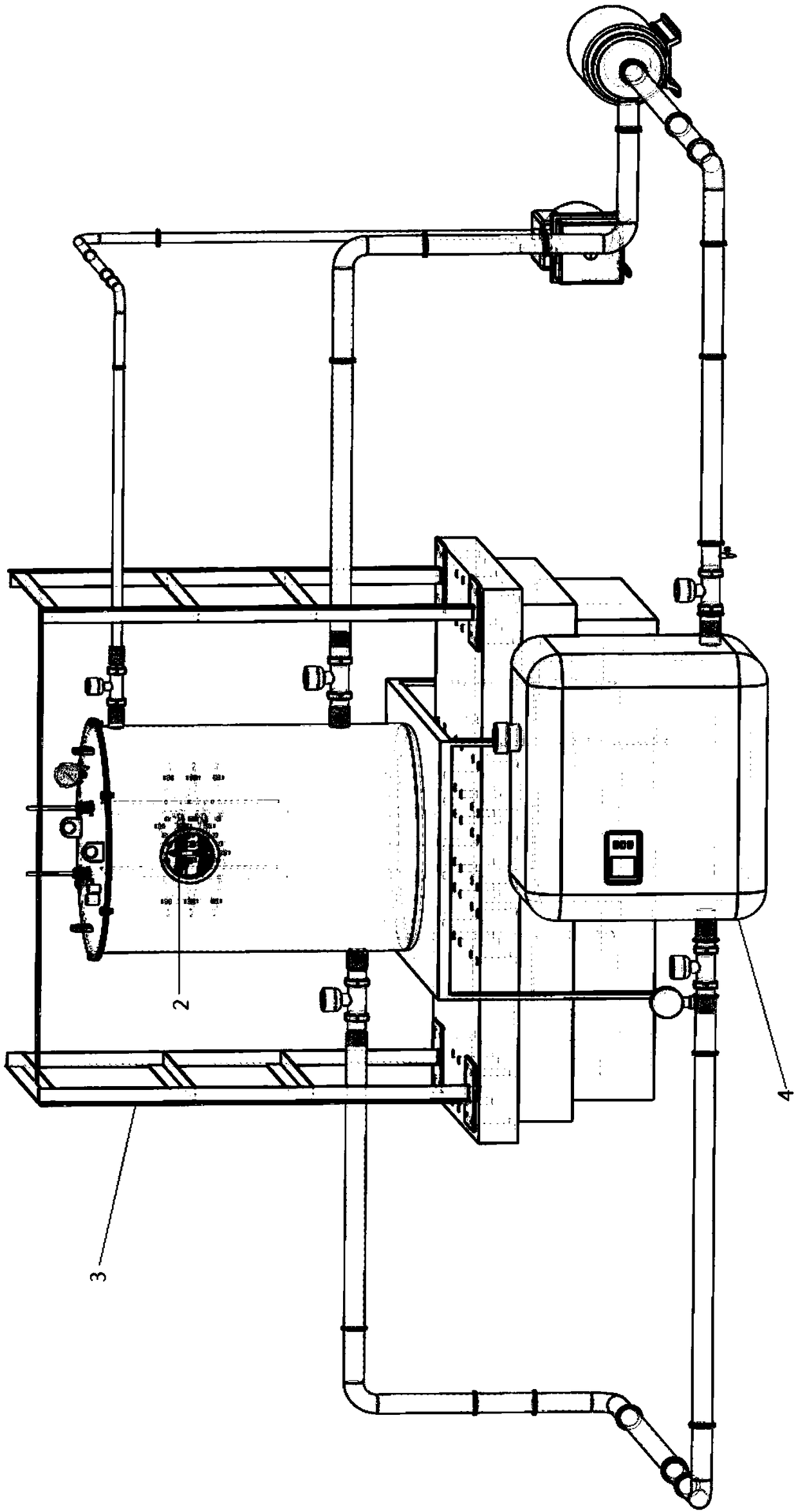

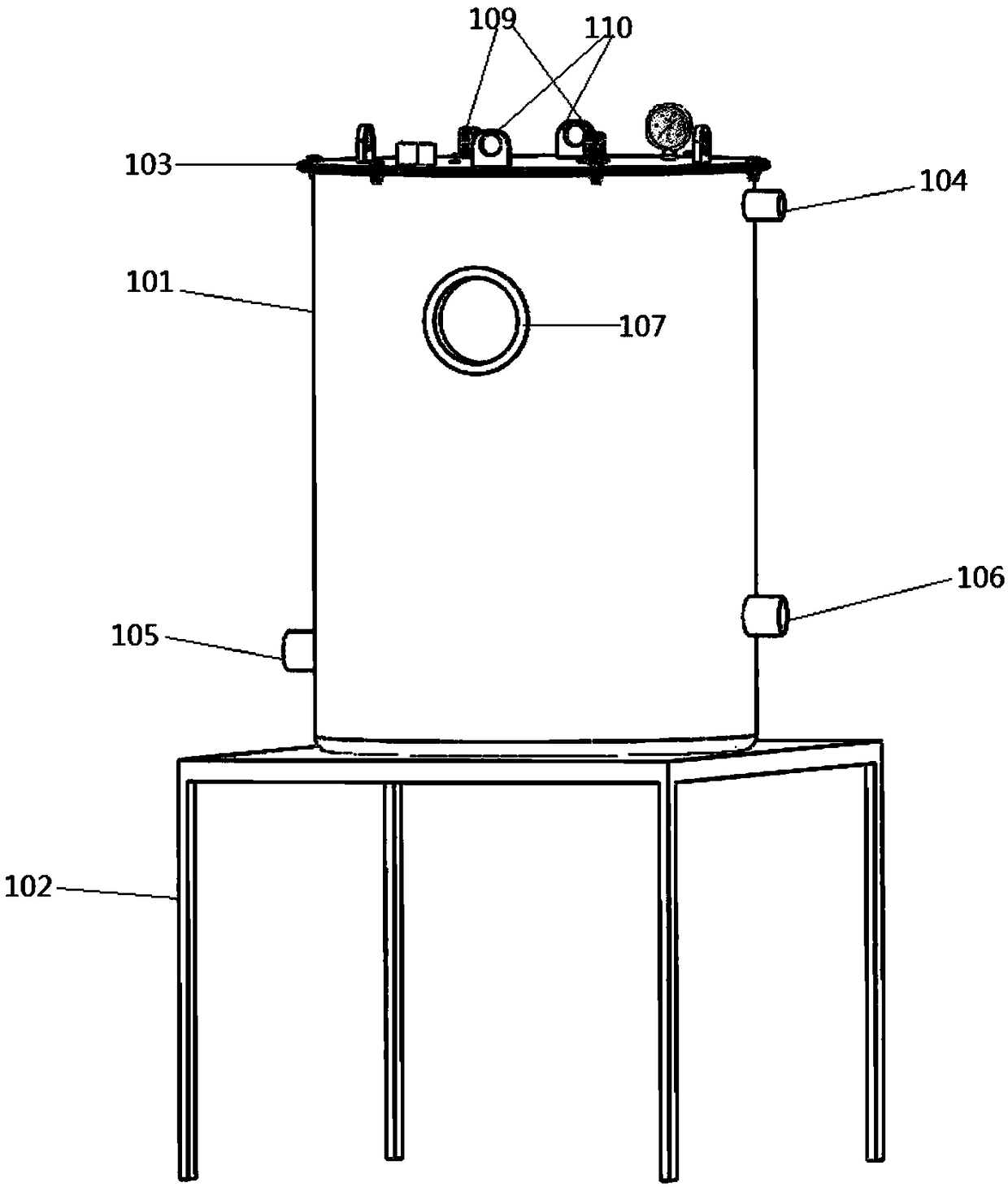

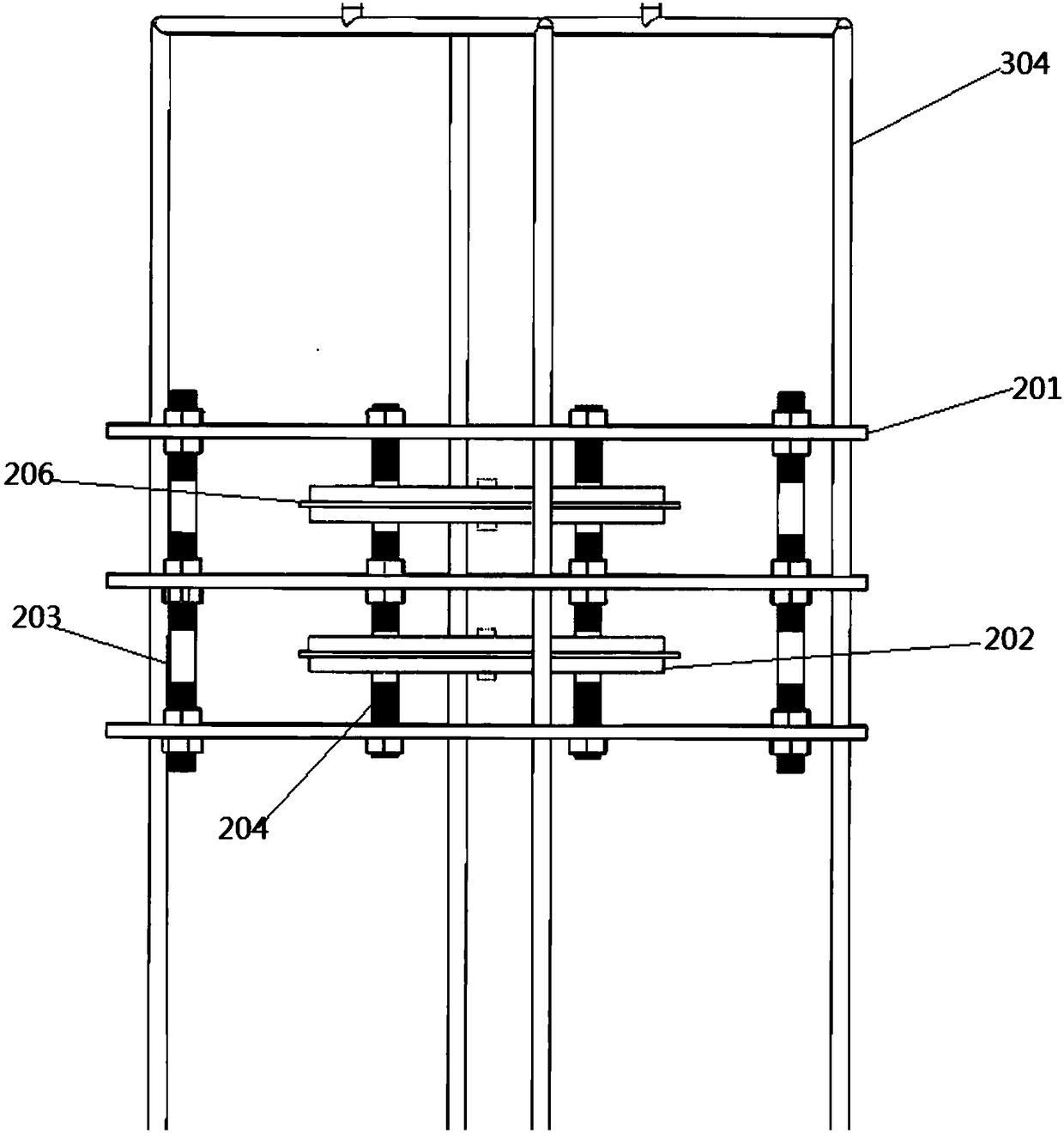

[0037] This embodiment discloses a transformer oil-paper insulation multi-factor combined aging test device, including a test box 101, a vibration transmission device 3, a sample clamping device 2 and an oil circuit circulation device 4; the test box 101 is set on a load-bearing On the platform 102, several groups of sample holding devices 2 arranged in parallel are arranged in the test box 101, the sample holding devices 2 are connected with the vibration transmission device 3, and the test box 101 is processed There is a vacuum pumping port 104, a circulating oil inlet 105 and a circulating oil outlet 106. The circulating oil inlet 104 and the circulating oil outlet 105 on the test box 101 pass through the oil circulation pipeline 402 and the oil circulation device 4 respectively. connected, the vacuum pumping port 104 on the test box 101 is connected with the vacuum pump 501 through the pumping line 502, and the pumping valve 503 is also arranged on the pumping line 502; the...

Embodiment 2

[0044] A method for predicting the life of a transformer oil-paper insulation multi-factor combined aging test device, the method comprising the following steps:

[0045] Step a: Pretreat the insulation sample 206 and dry it under vacuum for 48 hours;

[0046] Step b: After fixing the sample splint 201, the test electrode 202, and the insulating sample 206, after connecting the relevant pipelines, after heating to the specified temperature through the insulating oil buffer 403, use the circulating oil pump 401 to inject oil into the test box 101; Turn on the vacuum pump 501 during the oil filling process to make the test chamber 101 reach the specified vacuum degree. After the oil filling is completed, continue to vacuumize to the residual pressure of 40-50Pa and keep it for 6 hours;

[0047] Step c: Make multiple groups of samples undergo accelerated aging tests under the conditions of specified temperature, voltage and vibration frequency, and at specified intervals, detect ...

Embodiment 3

[0053] A multi-factor aging life prediction method for transformer oil-paper insulation includes the following steps:

[0054] Step a: select 12cm×12cm, insulation samples with a thickness of 1mm and divide them into two groups for degradation test under different conditions. Firstly, the transformer treatment process is simulated, the insulation sample is pretreated, and dried under vacuum for 48 hours.

[0055] Step b: After fixing the insulating sample and the test electrode, connect the relevant pipelines according to the diagram, heat the insulating oil through the insulating oil buffer, and then use the circulating oil pump to fill the test box with oil; turn on the vacuum pump during the oil filling process, Make the test box reach the specified vacuum degree, continue to vacuumize to the residual pressure of 40-50Pa after oil filling, keep it for 6 hours, and then close the vacuum valve.

[0056] Step c: FDS frequency domain spectrum test is carried out on the insulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com