Automatic hydride generating system used for organotin headspace solid-phase microextraction

A hydride generation and organotin technology, applied in the field of automatic hydride generation systems, can solve the problems of cumbersome process, time-consuming, laborious, poor test result reproducibility, etc., and achieve the effect of high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

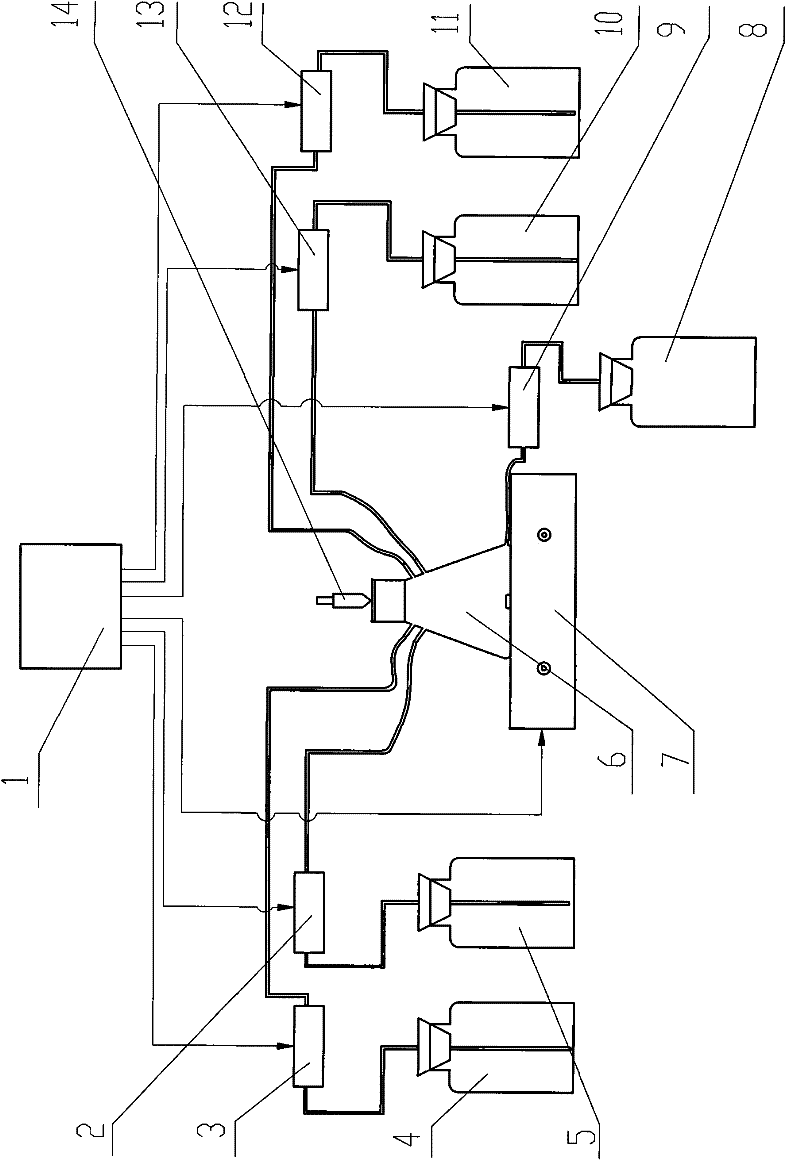

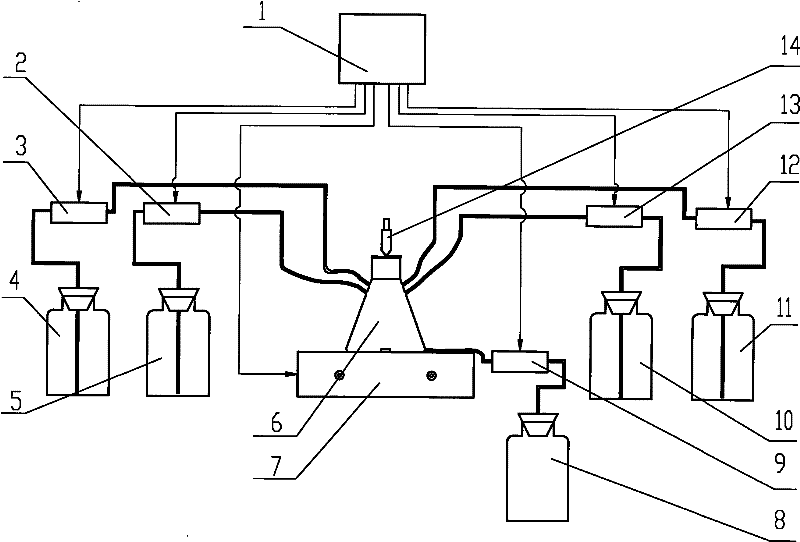

[0014] The present invention comprises a control unit 1, a hydride generating bottle 6, a first micrometering pump 3, a second micrometering pump 2, a first peristaltic pump 12, a second peristaltic pump 13 and a third peristaltic pump 9; the control unit 1 The corresponding output terminals of the first micrometering pump 3, the second micrometering pump 2, the first peristaltic pump 12, the second peristaltic pump 13 and the control ends of the third peristaltic pump 9 are respectively connected; the first micrometering pump 3, The inlets of the second micro metering pump 2, the first peristaltic pump 12 and the second peristaltic pump 13 are respectively communicated with the buffer solution bottle 4, the hydrogenation reagent bottle 5, the sample bottle 11 to be tested and the pure water bottle 10 through pipelines. The outlets of the micrometering pump 3, the second micrometering pump 2, the first peristaltic pump 12 and the second peristaltic pump 13 communicate with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com