Thimble module and method for separating wafer and blue tape using the module

A thimble, blue film technology, applied in the direction of fine work equipment, work accessories, stone processing equipment, etc., can solve the problems of moving parts, many times, difficult to improve the crystal speed, complex structure of the crystal bonding machine, etc., to achieve the number of movements The effect of simplification, improved production efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

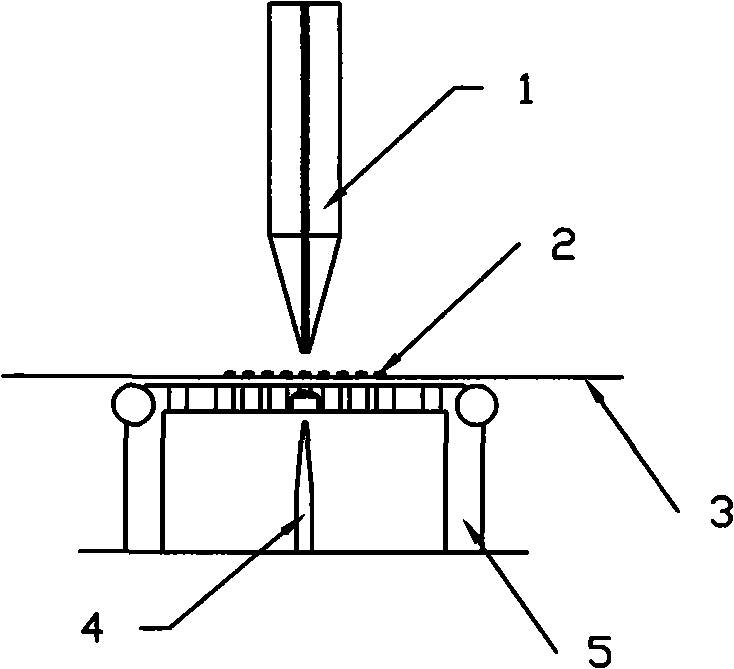

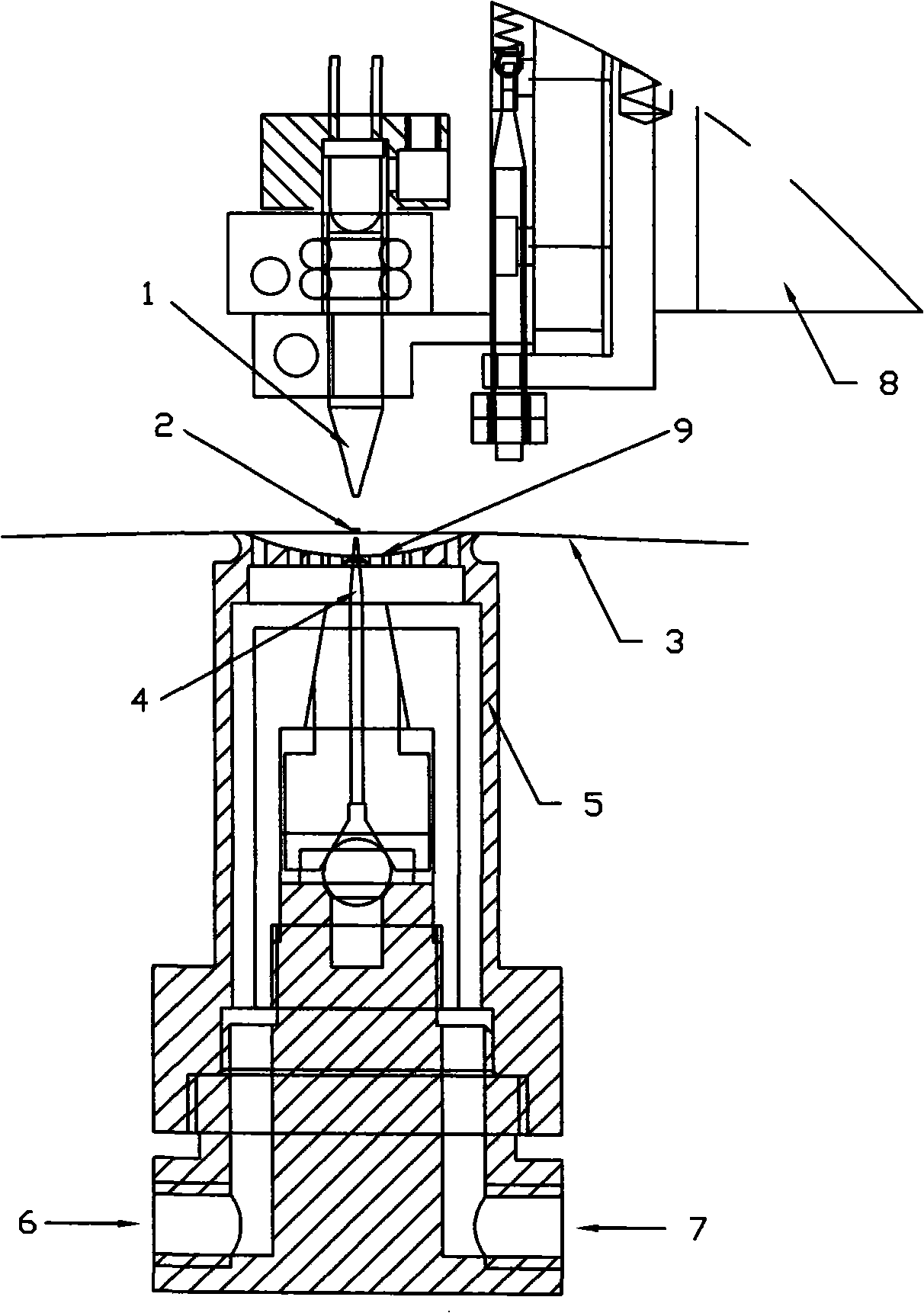

[0022] Such as figure 2 , image 3 A thimble module shown is fixedly installed on the machine table, and includes a thimble ring 5 and a thimble 4 .

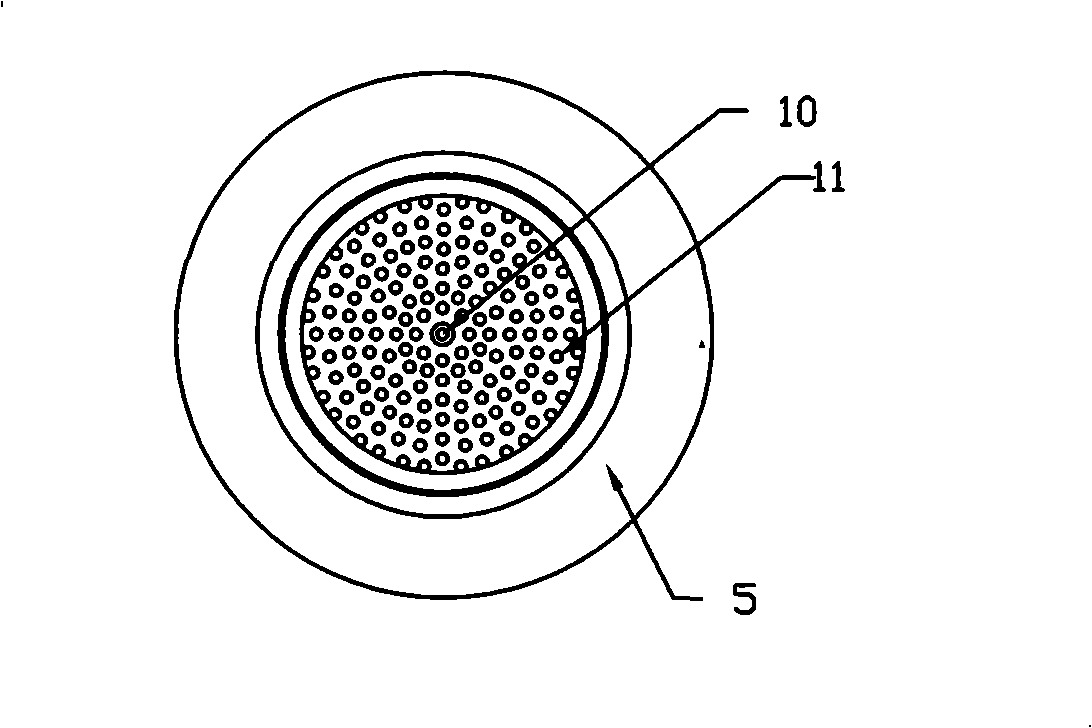

[0023] The thimble ring 5 and the thimble 4 are integrated and cannot move relatively. The upper end surface of the thimble ring 5 is an adsorption surface 9 . The adsorption surface 9 is a concave spherical surface, and the adsorption surface 9 is provided with a plurality of vertically arranged airflow holes 11 and a thimble hole 10, wherein the thimble hole 10 is located at the center of the sphere. The thimble ring 5 is also provided with a vacuum passage 6 and an air blowing passage 7, and the vacuum passage 6 and the air blowing passage 7 communicate with the airflow hole 11 on the adsorption surface.

[0024] The lower end of the thimble 4 is fixed on the thimble seat 5 , the upper end is a needle point, and the needle point passes through the thimble hole 10 .

[0025] The working process of the above-mentioned thim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com