Low-odor low-VOC polypropylene composite material, preparation device and method thereof

A composite material and polypropylene technology, applied in the field of organic polymer materials, can solve problems such as strength, stability, processability, and functionality that cannot meet the requirements of use, its own performance limitations, harmful VOC, etc., to avoid significant hygroscopicity Increase, avoid secondary pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

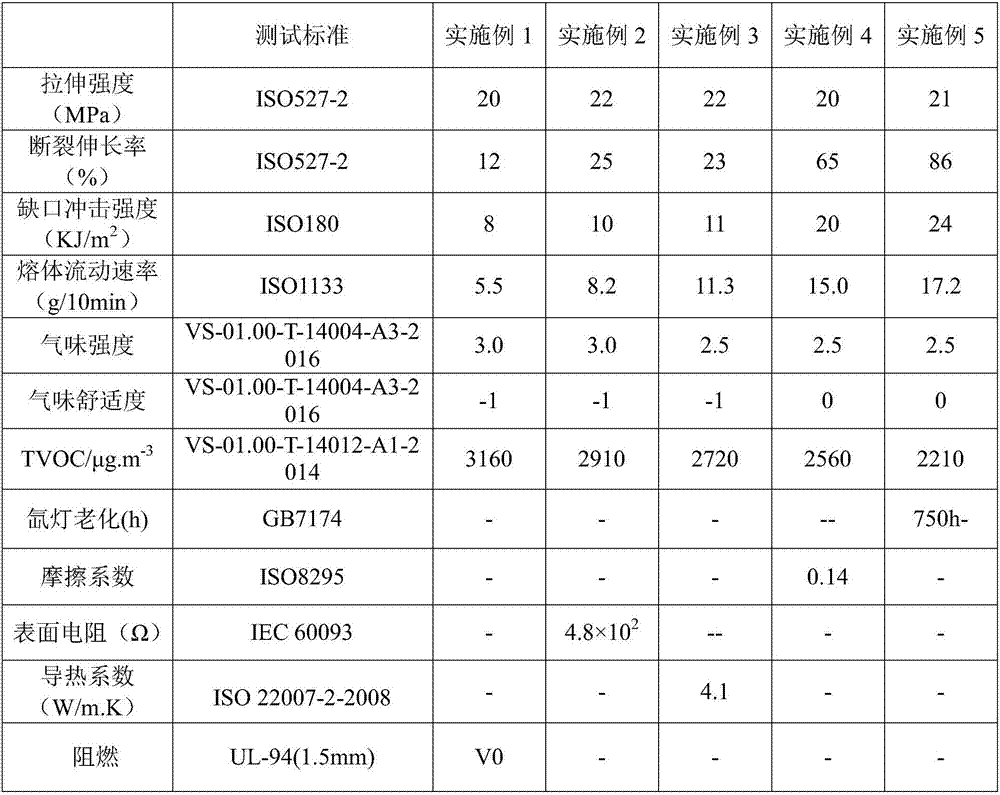

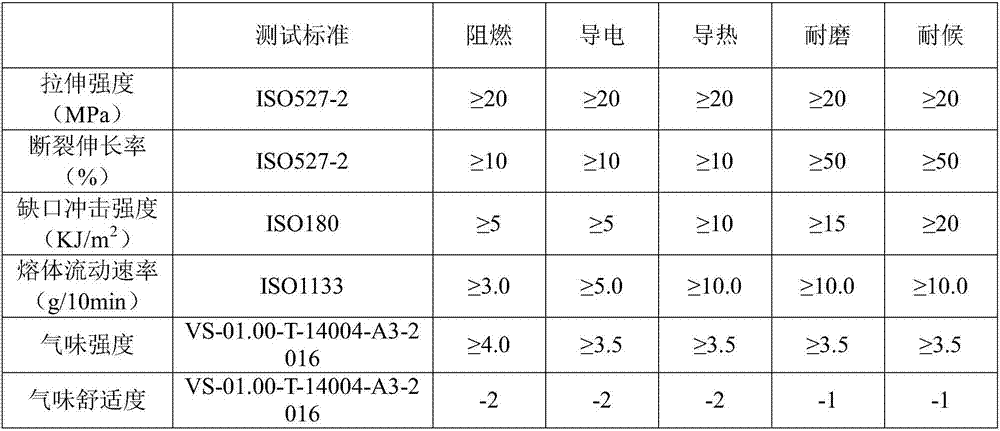

[0021] Preparation of low-odor, low-VOC flame-retardant polypropylene composites

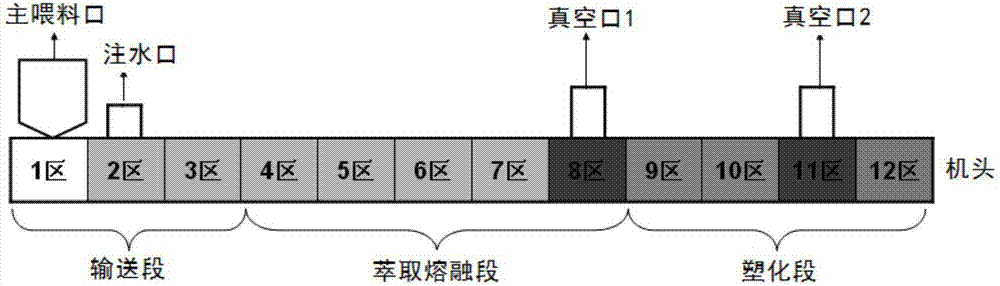

[0022] Weigh 56 parts of polypropylene resin, 20 parts of calcium carbonate, 20 parts of flame retardant, 0.3 parts of antioxidant 1010, 168, 2.0 parts of polyol wax, 0.1 part of silicone oil, mix and add to the machine barrel, control the screw speed to 350rpm , through the screw, the mixture first passes through the conveying section of the barrel, and 1.5 parts of water is added to the water injection port in zone 2. The temperature in zone 1-3 in the conveying section is 70°C, and then enters the extraction and melting section of the barrel for heating and melting, extraction and melting The temperatures in zones 4-8 in the section are 170°C, 180°C, 190°C, 190°C, and 200°C respectively. After full extraction, carry out vacuum extraction through vacuum port 1 with a vacuum degree of -0.08MPa to remove water and dissolve in water. Harmful volatile organic compounds; then enter the plasticizing...

Embodiment 2

[0024] Preparation of low-odor, low-VOC conductive polypropylene composites

[0025] Weigh 67 parts of polypropylene resin, 15 parts of calcium carbonate, 15 parts of conductive agent, 0.2 part of antioxidant 1010, 1.5 parts of polyol wax, and 0.08 part of silicone oil, add them to the machine barrel after mixing, control the screw speed to 360rpm, and make the The mixture first passes through the conveying section of the machine barrel, and 1.8 parts of water is added to the water injection port of zone 2; the temperature of zone 1-3 in the conveying section is 60°C, and then enters the extraction and melting section of the barrel for heating and melting, and the 4- The temperatures in the 8 zones are respectively 170°C, 180°C, 190°C, 190°C, and 200°C. After full extraction, vacuum extraction is carried out through the vacuum port 1. The vacuum degree is -0.08MPa to remove water and harmful volatile substances dissolved in water. Organic matter; then enter the plasticizing se...

Embodiment 3

[0027] Preparation of low-odor, low-VOC thermally conductive polypropylene composites

[0028] Weigh 77 parts of polypropylene resin, 10 parts of talcum powder, 10 parts of thermal conductive agent, 0.4 parts of antioxidant 1010 and 168, 1.0 part of polyol wax, and 0.06 part of silicone oil, mix them and add them to the barrel, and control the screw speed to 380rpm. Through the screw, the mixture first passes through the conveying section of the barrel, and 2.0 parts of water is added to the water injection port in zone 2; the temperature in zone 1-3 in the conveying section is 60°C, and then enters the extraction and melting section of the barrel for heating and melting, and the extraction and melting section The temperatures in zones 4-8 are respectively 170°C, 180°C, 190°C, 200°C, and 210°C. After full extraction, vacuum extraction is carried out through the vacuum port 1. The vacuum degree is -0.08MPa to remove water and dissolved in water. Harmful volatile organic compoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com