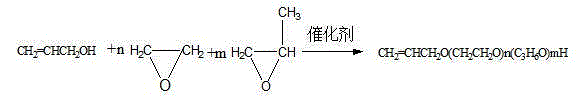

High-double bond content allyl polyether production method

A technology of allyl polyether and production method, which is applied in the fields of ether preparation, alkylene oxide preparation ether, organic chemistry, etc. It can solve the problems of difficult catalyst preparation, wide molecular weight distribution, low double bond content, etc., and achieve improved safety , time shortening, and the effect of speeding up the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of catalyst sodium allyl alcohol solution in allyl alcohol:

[0025] Inject 300kg of propylene alcohol into two external circulation stirred reactors equipped with refrigerated condensate reflux, start the stirring and external circulation pump, after nitrogen replacement, open the hydrogen discharge valve and nitrogen automatic replenishment valve, and continue to heat up to 50°C Add 10kg of sodium metal to react, open the jacket of the reaction kettle and the cooling water of the external circulation cooler to ensure the reaction temperature is 60-65°C, after adding the sodium metal, keep it warm for the reaction, when the hydrogen analyzer shows that no hydrogen is produced, cool down to 40°C and exit Feed to obtain 310kg of catalyst sodium acrylate propylene alcohol solution.

[0026] (2) Preparation of allyl polyether:

[0027] Pump 6kg of the catalyst sodium acrylate propylene alcohol solution in step (1) and 52kg of propylene alcohol into the rea...

Embodiment 2

[0031] (1) Preparation of catalyst sodium allyl alcohol solution in allyl alcohol:

[0032] Pump a certain amount of 250kg of propylene alcohol into two external circulation stirred reactors equipped with refrigerated condensate reflux, start the stirring and external circulation pump, after nitrogen replacement, open the hydrogen discharge valve and nitrogen automatic replenishment valve, and raise the temperature to 50°C Afterwards, add 10kg of sodium metal continuously for reaction, open the jacket of the reaction kettle and the cooling water of the external circulation cooler to ensure the reaction temperature is 70-75°C. ℃ discharge to obtain 260 kg of catalyst sodium acrylate allyl alcohol solution.

[0033] (2) Preparation of allyl polyether:

[0034] Pump 52kg of the catalyst sodium acrylate propylene alcohol solution in step (1) and up to 8kg of propylene alcohol into the reaction kettle. After replacing the air with nitrogen, feed 1942kg of epoxy compound to react, ...

Embodiment 3

[0037] (1) Preparation of catalyst sodium allyl alcohol solution in allyl alcohol:

[0038]Pump a certain amount of 200kg of propylene alcohol into two external circulation stirred reactors equipped with refrigerated condensate reflux, start the stirring and external circulation pump, after nitrogen replacement, open the hydrogen discharge valve and nitrogen automatic replenishment valve, and raise the temperature to 50°C Afterwards, add 10kg of sodium metal continuously for reaction, open the jacket of the reactor and the cooling water of the external circulation cooler to ensure the reaction temperature is 65-70°C. °C discharge to obtain 210 kg of catalyst sodium acrylate allyl alcohol solution.

[0039] (2) Preparation of allyl polyether:

[0040] Pump 56kg of the catalyst sodium acrylate propylene alcohol solution in step (1) and 5kg of propylene alcohol into the reaction kettle. After replacing the air with nitrogen, 3942kg of epoxy compounds are introduced to react, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com