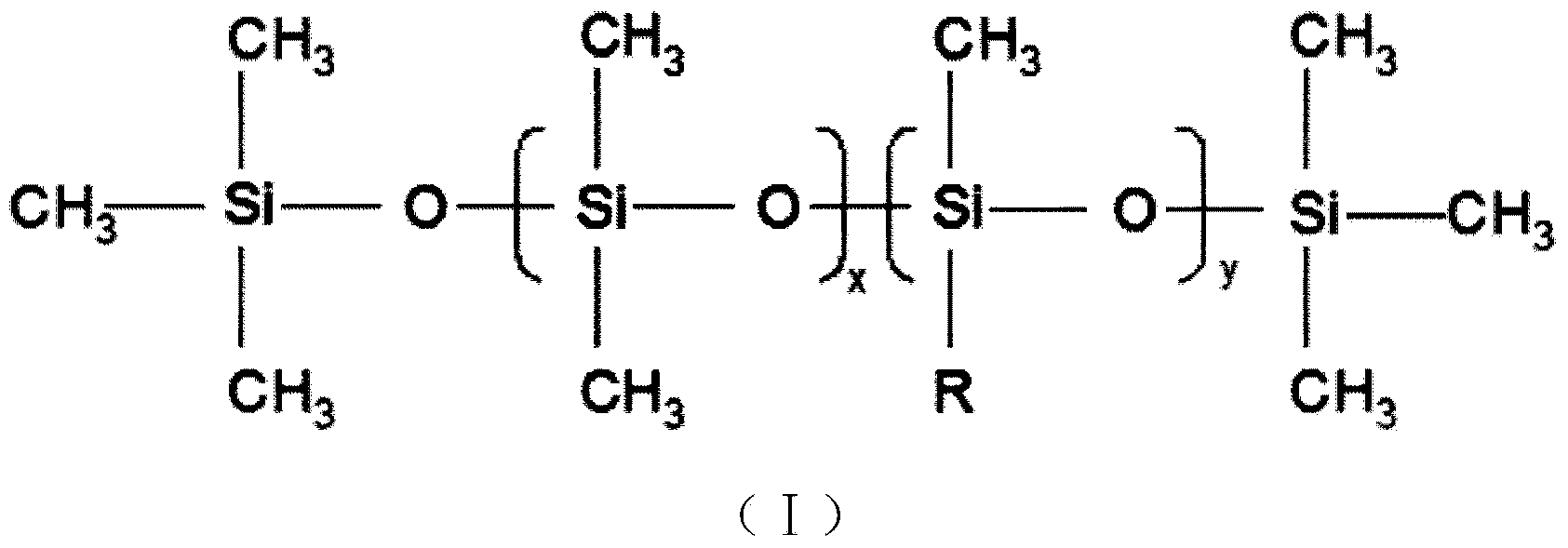

Preparation method of organosilicon foam stabilizer applied to single-component polyurethane foam sealing agent

A technology of silicone foam and polyurethane foam, applied in the field of foam stabilizers, can solve the problems of poor fluidity, poor dimensional stability and low foaming ratio of the foaming system, and achieve enhanced shrinkage resistance, improved fluidity, and uniform cells. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

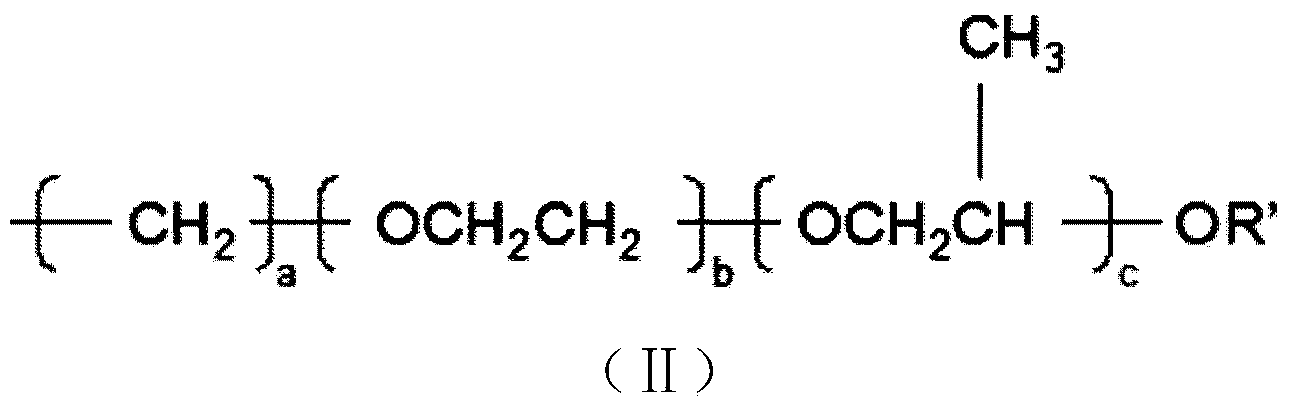

[0028] (1) Add 45g of allyl alcohol, 50g of ethylene oxide, 4.5g of propylene oxide, and 0.5g of KOH into the reaction kettle, control the temperature at 90°C and the reaction pressure at 0.5MPa, and react for 4 hours. When the system When the pressure drops to less than 0.15MPa, the temperature is lowered to stop the reaction, and after neutralization, filtration and extraction treatment, an allyl-terminated copolyether containing ethylene oxide and propylene oxide groups is obtained;

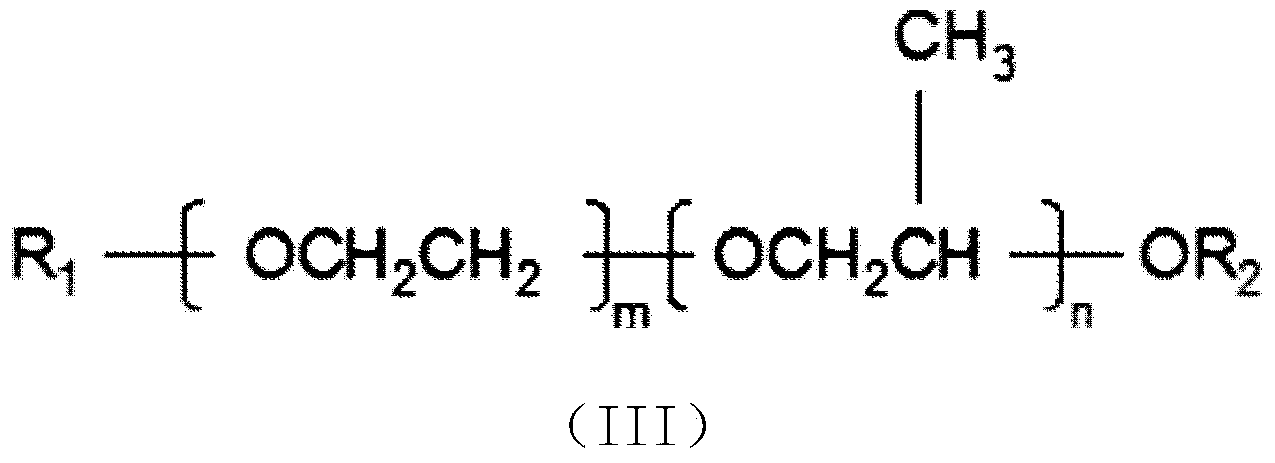

[0029] (2) React 35g of the polyether prepared in step (1) with a small piece of metal sodium at a temperature of 90°C, pass through an excess of halogenated alkanes, and react for 4 hours. After the above reaction is completed, add distilled water to the system and stir. Lower the temperature to 80°C, adjust the pH value to 6.5, and let it stand until the oil-water two-phase layer is separated, remove the water phase, vacuumize the obtained oil phase, add a decolorant and filter to obtain a me...

Embodiment 2

[0033] (1) Add 170g of allyl alcohol, 10g of ethylene oxide, 19.8g of propylene oxide, and 0.2g of NaOH into the reaction kettle, and react for 6 hours under the conditions of controlling the temperature at 120°C and the reaction pressure at 0.4MPa. When the system When the pressure drops to less than 0.15MPa, the temperature is lowered to stop the reaction, and after neutralization, filtration and extraction treatment, an allyl-terminated copolyether containing ethylene oxide and propylene oxide groups is obtained;

[0034] (2) React 65g of the polyether prepared in step (1) with a small piece of metal sodium at a temperature of 115°C, pass through an excess of halogenated alkanes, and react for 6 hours. After the above reaction is completed, add distilled water to the system and stir. Lower the temperature to 80°C, adjust the pH value to 7.0, and let it stand until the oil-water two-phase layer is separated, remove the water phase, vacuumize the obtained oil phase, add a deco...

Embodiment 3

[0038] (1) Add 120g of allyl alcohol, 77g of ethylene oxide, 2g of propylene oxide, and 1.0g of NaOH into the reaction kettle, and react for 5 hours under the conditions of controlling the temperature at 130°C and the reaction pressure at 0.4MPa. When the system pressure When the temperature is lowered to less than 0.15MPa, the temperature is lowered to stop the reaction, and after neutralization, filtration and extraction treatment, an allyl-terminated copolyether containing ethylene oxide and propylene oxide groups is obtained;

[0039](2) React 55g of the polyether prepared in step (1) with a small piece of sodium metal at a temperature of 120°C, pass through an excess of halogenated alkanes, and react for 5 hours. After the above reaction is completed, add distilled water to the system and stir. Lower the temperature to 80°C, adjust the pH value to 7.0, and let it stand until the oil-water two-phase layer is separated, remove the water phase, vacuumize the obtained oil phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com