High-efficiency organic silicon defoaming agent

A silicone defoamer, high-efficiency technology, applied in the direction of foam dispersion/prevention, can solve the problems of unfavorable promotion, high production cost, complicated process, etc., and achieve good adaptability, fast defoaming speed and less dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

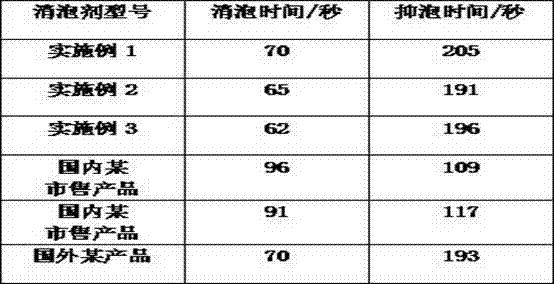

Examples

Embodiment 1

[0016] In a stainless steel electric heating reactor, add 50g of KF-96 and 20g of 201 silicone oil, raise the temperature to 200°C, start the agitator (120r / min), add 5g of fumed silica, and stir for 30 minutes to fully homogenize the two materials , heated up to 250°C, added 8g dispersant IW, 3g dispersing solubilizer S, 5g polyether F-6, 4g polyether F68, 12g sorbitan monostearate (Span60), 12g sorbitan monostearate Acetate polyoxyethylene ether (Tween60), then add 5g of water, keep it warm for 2 hours, cool down to 100°C, then add 15g of water, stir and naturally cool down to 80°C, and discharge under stirring.

Embodiment 2

[0018] In a stainless steel electric heating reactor, add 25g of KF-96 and 55g of 201 silicone oil, raise the temperature to 200°C, start the agitator (120r / min), add 4g of fumed silica, and stir for 30 minutes to fully homogenize the two materials , heated up to 250°C, added 6g dispersant IW, 4g dispersing solubilizer S, 8g polyether F-6, 5g polyether F38, 7g sorbitan monostearate (Span60), 7g sorbitan monostearate Acetate polyoxyethylene ether (Tween60), add 8g of water, keep warm for 2 hours, cool down to 100°C, then add 12g of water, stir and naturally cool down to 80°C, and discharge under stirring.

Embodiment 3

[0020] In a stainless steel electric heating reaction kettle, add 40g of KF96 and 40g of 201 silicone oil, raise the temperature to 200°C, start the agitator (120r / min), add 3g of fumed silica, stir for 30 minutes to fully homogenize the two materials, and raise the temperature To 250°C, add 9g dispersant IW, 5g dispersing solubilizer S, 7g polyether F-6, 6g polyether F68, 8g sorbitan monostearate (Span60), 8g sorbitan monostearate Ester polyoxyethylene ether (Tween60), add 12g of water, keep it warm for 2 hours, cool down to 100°C, then add 10g of water, stir and naturally cool down to 80°C, and discharge under stirring.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com