In-situ polymerization intercalated composite gel material and its preparation method and application

A composite gel, in-situ polymerization technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem of inability to achieve interfacial bonding, difficulty in obtaining nano-scale uniform blending, and difficulty in completely eliminating fillers and polymers. Problems such as the interfacial tension of the substrate, to achieve the effect of low production cost, easy operation and good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, preparation multi-quaternary ammonium salt type clay interlayer modifier

[0041] Put 32.4g (0.1mol) of ricinoleic acid into 15mL of xylene and 1.02g (0.01mol) of aluminum oxide into the reactor, after heating to 180°C, drop 5.3g of ricinoleic acid into the reaction solution with a dropping funnel (0.0515mol) of diethylenetriamine, the reaction is continuously separated by a water separator, stirred for 1.5hour, and evaporated to remove xylene to obtain bisamide;

[0042] Add 43.6g (0.05mol) of bisamide and 12ml of ethanol into the reactor, heat to 30°C, and drop 23g (0.05mol) of 3-chloro-2-hydroxypropyltrimethyl into the reaction system with a dropping funnel Ammonium chloride solution, heated up to 70°C, stirred and reacted for 2 hours to obtain multi-quaternary ammonium salt type clay interlayer modifier.

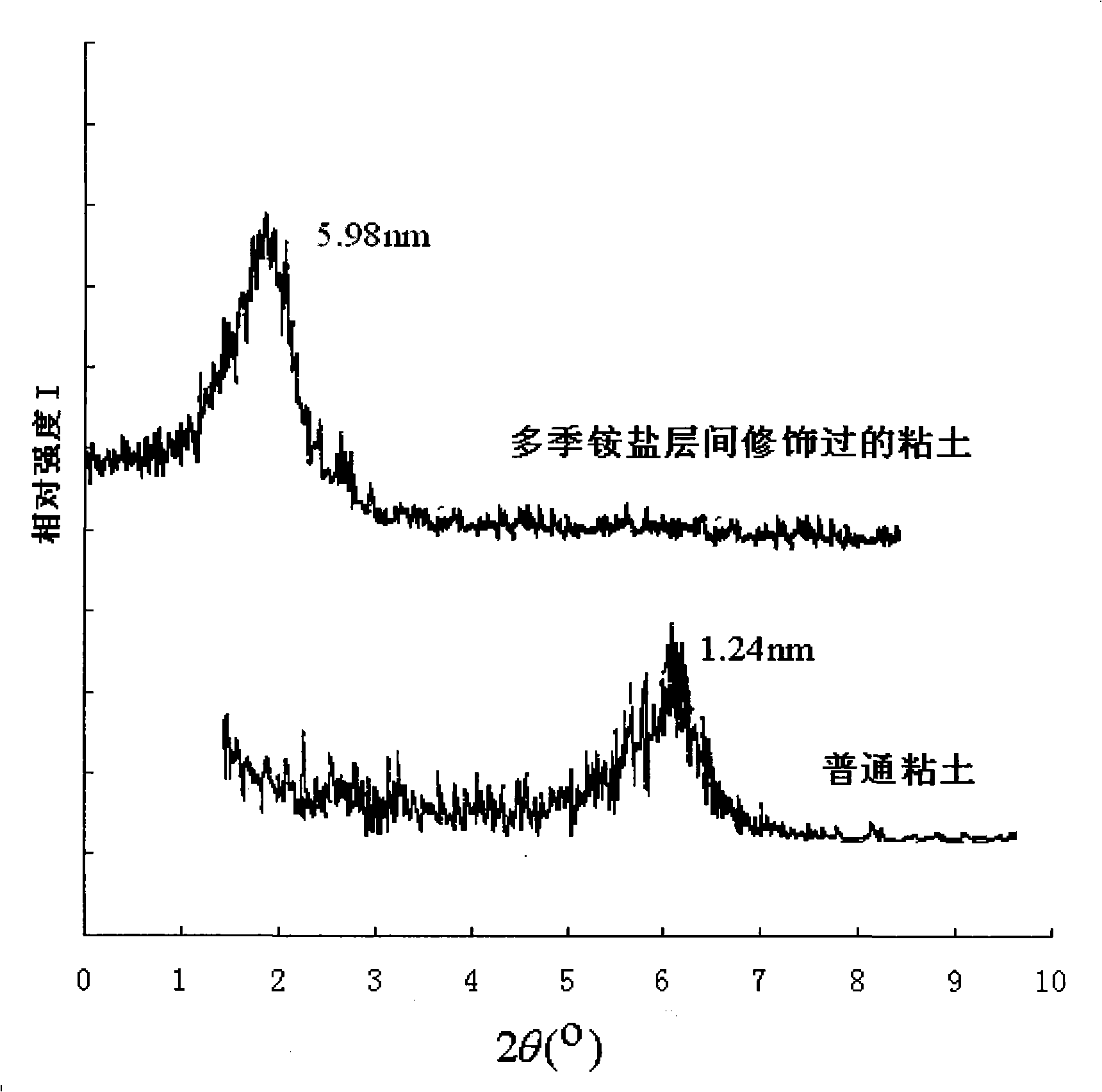

[0043] From attached figure 1 It can be seen that the interlayer distance of the clay modified by this clay interlayer modifier increases from the...

Embodiment 2

[0044] Embodiment 2, preparation multi-quaternary ammonium salt type clay interlayer modifier

[0045] Put 32.4g (0.1mol) of ricinoleic acid into 15mL of xylene and 1.02g (0.01mol) of aluminum oxide into the reactor. After heating to 220°C, add 5.3g of ricinoleic acid dropwise to the reaction solution with a dropping funnel (0.0515mol) of diethylenetriamine, the reaction is continuously separated by a water separator, stirred for 2.5hours, and evaporated to remove xylene to obtain bisamides;

[0046] Add 43.6g (0.05mol) of bisamide and 12ml of ethanol into the reactor, heat to 40°C, and drop 23g (0.05mol) of 3-chloro-2-hydroxypropyltrimethyl into the reaction system with a dropping funnel The ammonium chloride solution was heated to 80° C., stirred and reacted for 4 hours to obtain a multi-quaternary ammonium salt-type clay interlayer modifier.

Embodiment 3

[0047] Embodiment 3, preparation multi-quaternary ammonium salt type clay interlayer modifier

[0048] Put 32.4g (0.1mol) of ricinoleic acid into 15mL of xylene and 1.02g (0.01mol) of aluminum oxide into the reactor. After heating to 200°C, add 5.3g of ricinoleic acid dropwise to the reaction solution with a dropping funnel (0.0515mol) of diethylenetriamine, the reaction is continuously separated by a water separator, stirred for 2.0hours, and evaporated to remove xylene to obtain bisamides;

[0049] Add 43.6g (0.05mol) of bisamide and 12ml of ethanol into the reactor, heat to 35°C, and drop 23g (0.05mol) of 3-chloro-2-hydroxypropyltrimethyl into the reaction system with a dropping funnel Ammonium chloride solution, heated up to 75°C, stirred and reacted for 3 hours to obtain multi-quaternary ammonium salt type clay interlayer modifier.

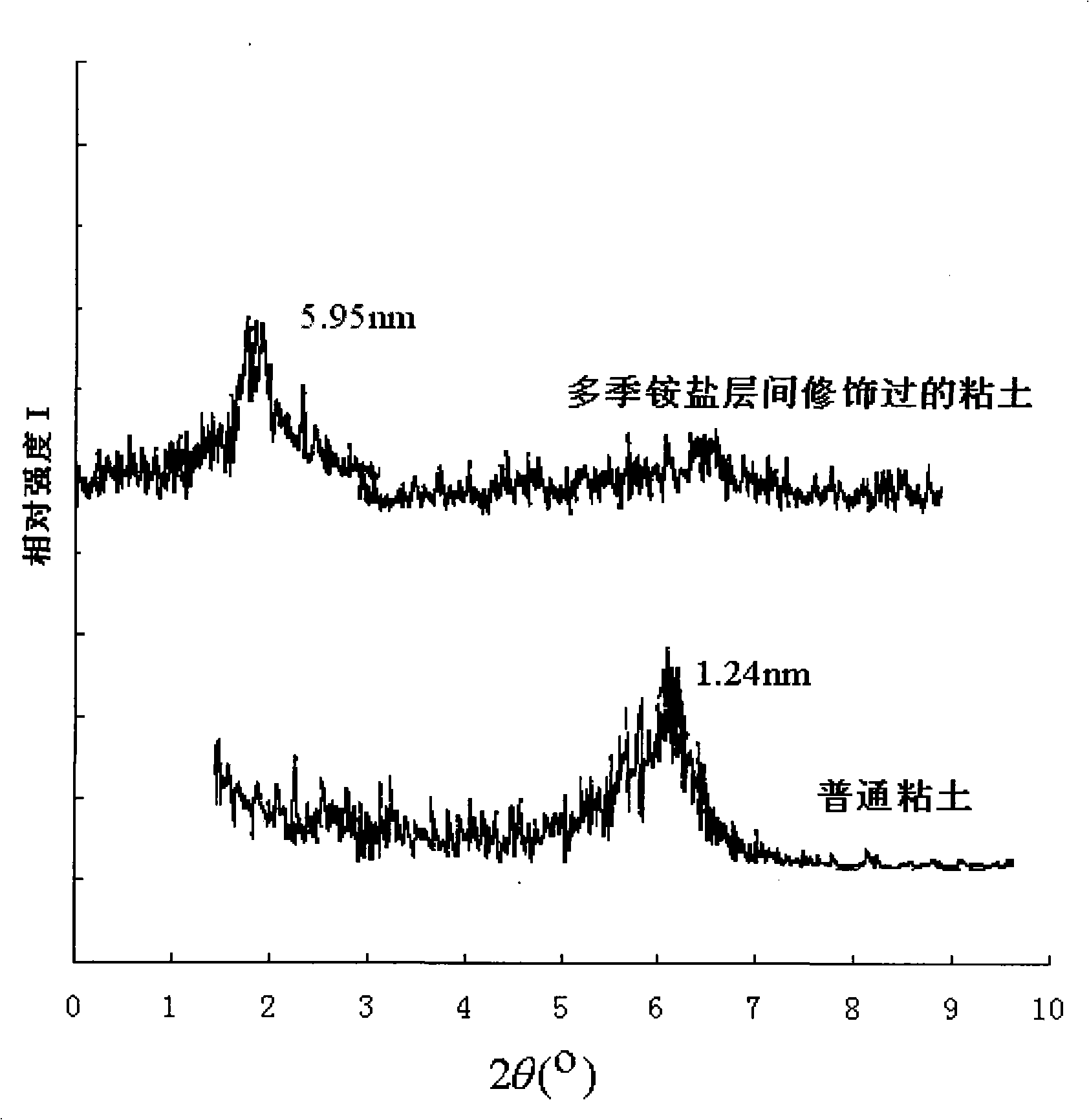

[0050] From attached figure 2 It can be seen that the interlayer distance of the clay modified by this clay interlayer modifier increases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com