Method for manufacturing organosilicon surfactant with T-shaped structure for pesticide

A surfactant and organosilicon technology, applied in the fields of botanical equipment and methods, organic silicon compounds, chemical instruments and methods, etc., can solve the problems of environmental and human harm, hydrogen chloride gas emission, etc., and reduce the amount of pesticides and catalysts. The effect of less amount and reducing pesticide residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

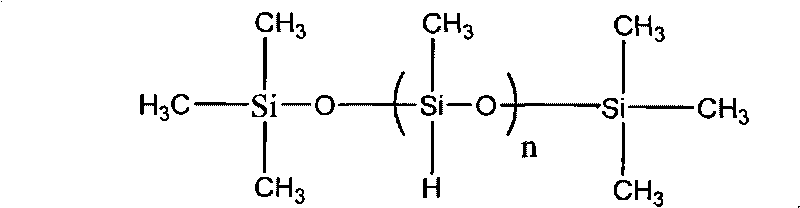

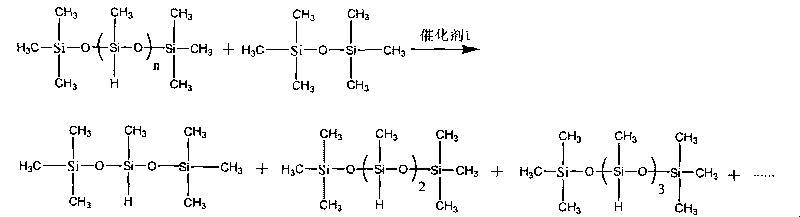

[0041] Add 50g of hydrogen-containing silicone oil (n=100), 900g of hexamethyldisiloxane and 1g of concentrated sulfuric acid into a 2L four-neck flask, control the temperature at 10°C while stirring, react for 12 hours, wash and dry with water, and then carry out Purified by rectification to obtain 111 g of hydrogen-containing trisiloxane with a content of 98%.

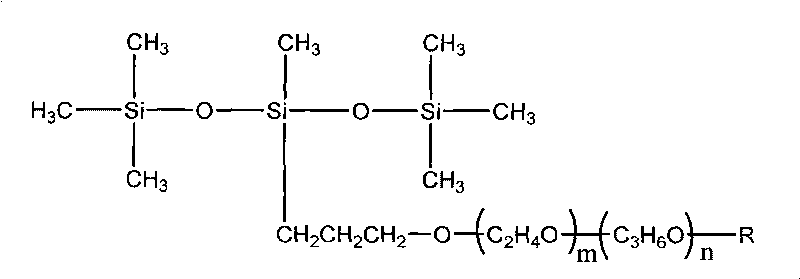

[0042] 70g98% hydrogen-containing trisiloxane and 930g allyl polyether (m=20, n=20, R=CH 3 ) into a 2L four-neck flask, heated to 120°C under stirring with nitrogen, added 1g of platinum-allyl polyether catalyst, reacted for 2 hours, vacuumed for 30 minutes, cooled to room temperature, and obtained 980g of silicone surfactant, The structure is as follows:

[0043]

Embodiment 2

[0045] Add 150g of hydrogen-containing silicone oil (n=5), 150g of hexamethyldisiloxane and 3g of perfluorosulfonic acid into a 500ml four-port reactor, control the temperature at 50°C under stirring, cool down after 8 hours, and remove The catalyst was then purified by rectification to obtain 198g of hydrogen-containing trisiloxane with a content of 98%;

[0046] Put 98g of hydrogen-containing trisiloxane with a content of 98% and 98g of allyl polyether (m=4, n=0, R=H) in a 250ml flask, heat up to 60°C under stirring with nitrogen, and add 2g of platinum-ene Propyl polyether catalyst, reacted for 12 hours, took off the vacuum for 30 minutes, cooled to room temperature, obtained 197g organic silicon surfactant, the structure is as follows:

[0047]

Embodiment 3

[0049] Add 20g of hydrogen-containing silicone oil (n=30), 100g of hexamethyldisiloxane and 30g of strongly acidic ion-exchange resin into a 250ml flask, control the temperature at 100°C while stirring, cool down after 6 hours of reaction, and filter out the resin , and then carry out rectification and purification to obtain 27g content of 98% hydrogen-containing trisiloxane;

[0050] 20g of hydrogen-containing trisiloxane with a content of 98%, 80g of allyl polyether (m=6, n=2, R=C 2 h 5 ) into the reactor, heated to 85°C under stirring with nitrogen, added 0.2g of platinum-allyl polyether catalyst, reacted for 6 hours, vacuumed for 30 minutes, cooled to room temperature, and obtained 98g of silicone surfactant, structure as follows:

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com