Method for making artificial leather release paper in radiation curing manner

A technology of radiation curing and artificial leather, which is applied in the direction of papermaking, paper machine, textile and papermaking, etc. It can solve the problems of lowering the production efficiency of artificial leather release paper, easy bottom leakage, and slow vehicle speed, so as to improve the curing rate and prevent bottom leakage. , full pattern effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

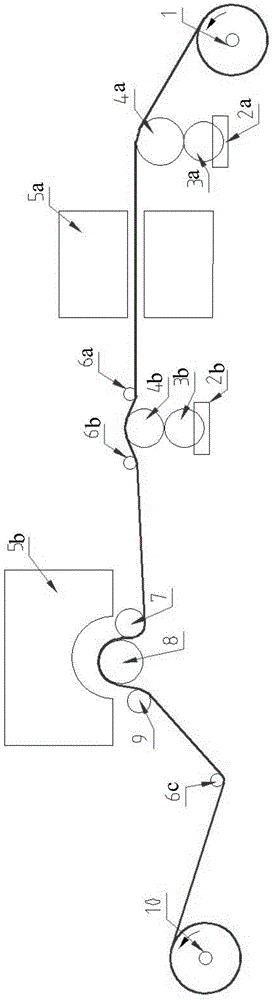

Method used

Image

Examples

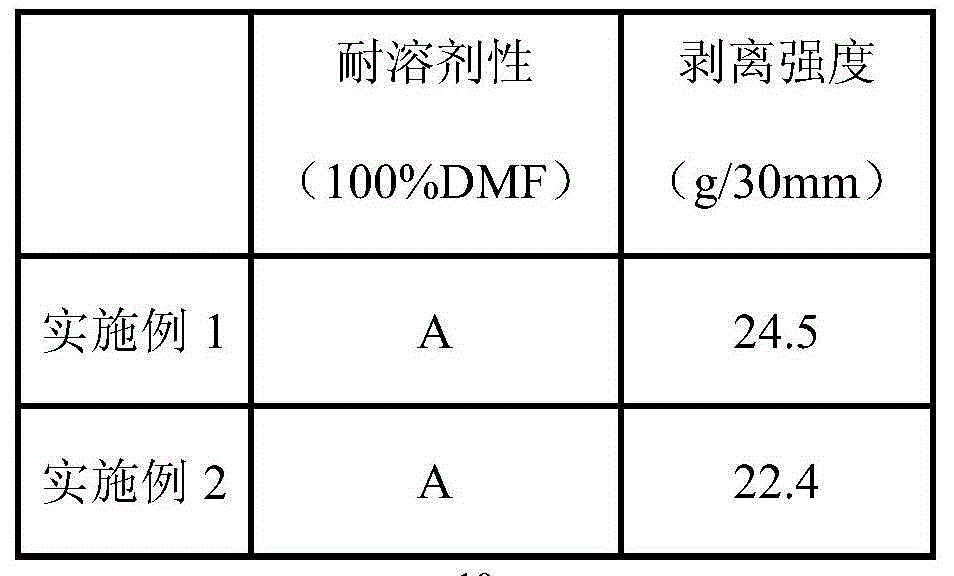

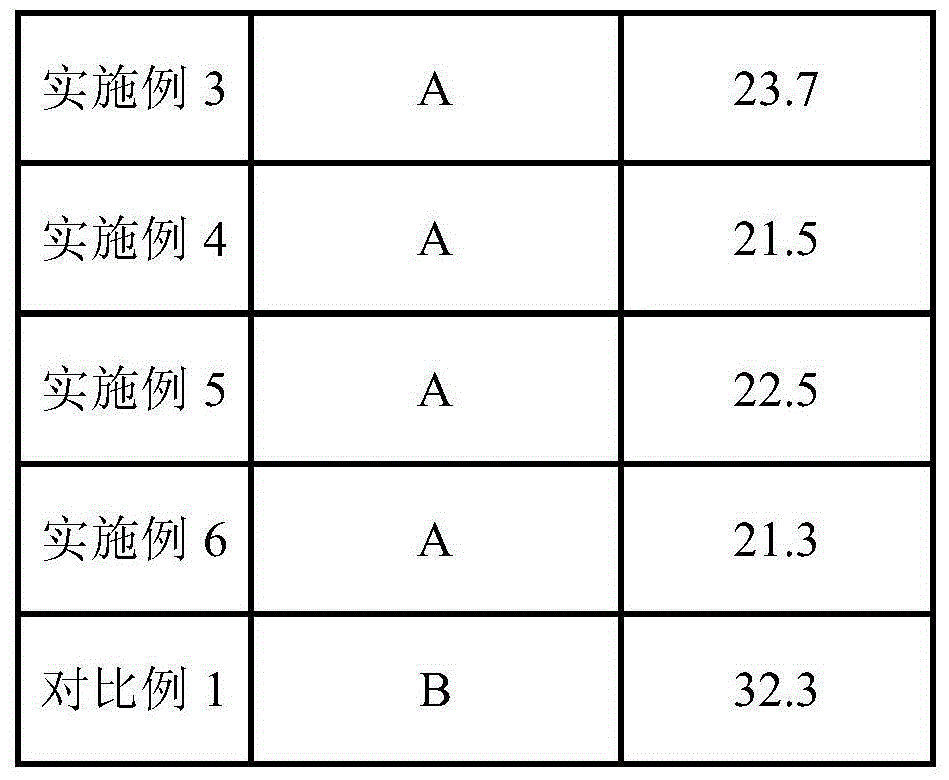

Embodiment 1

[0060] 80 parts by weight of aliphatic urethane acrylate (Heshan Lizhimen, LE-6706, functionality is 6), and 10 parts by weight of isooctyl methacrylate and 10 parts by weight of hydroxyethyl methacrylate are mixed After uniformity, 4 parts by weight of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide was added, and the mixture was stirred again to be uniform, and the operation should be protected from light to finally obtain a coating solution. Using the above-mentioned specific radiation curing device for making artificial leather release paper, the coating liquid is coated on the surface of the base paper by two-roller transfer coating twice. Base paper weight is 200g / m 2 , the width is 2000mm, and the thickness is 260μm. The coating amount of the first process is 50g / m 2 , UV curing, the wavelength is 370nm, the energy is 480w / cm, the coating amount of the second process is 100g / m 2 , solidified under the same conditions, and at the same time, patterned, the speed was c...

Embodiment 2

[0062] 60 parts by weight of aliphatic urethane acrylate (Shanghai Miki, the product of SM6621, with a functionality of 6), was mixed evenly with 20 parts by weight of isooctyl methacrylate and 20 parts by weight of hydroxyethyl methacrylate, Then add 6 parts by weight of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide, stir evenly again, pay attention to the operation in dark, and finally obtain the coating liquid. Using the above-mentioned specific radiation curing device for making artificial leather release paper, the coating liquid is coated on the surface of the base paper by two-roller transfer coating twice. Base paper weight is 150g / m 2 , the width is 2000mm, and the thickness is 200mm. The coating amount of the first process is 30g / m 2 , UV curing, the wavelength is 370nm, the energy is 300w / cm, and the coating amount of the second process is 70g / m 2 , solidify under the same conditions, and at the same time pattern forming, the speed of the vehicle is controlled...

Embodiment 3

[0064] Stir and mix 30 parts by weight of aliphatic urethane acrylate (Kesheng, Huizhou, UV613, with a functionality of 3) with 40 parts by weight of isooctyl methacrylate and 30 parts by weight of hydroxyethyl methacrylate, Then add 2 parts by weight of perphenylbis(2,4,6-trimethylbenzoyl)phosphine oxide, stir evenly again, pay attention to the operation in dark place, and finally obtain the coating liquid. Using the above-mentioned specific radiation curing device for making artificial leather release paper, the coating liquid is coated on the surface of the base paper by two-roller transfer coating twice. Base paper weight is 120g / m 2 , the width is 2000mm, and the thickness is 150μm. The coating amount of the first process is 10g / m 2 , UV curing, the wavelength is 370nm, the energy is 100w / cm, and the coating amount of the second process is 10g / m 2 , solidify under the same conditions, and at the same time pattern forming, the vehicle speed is controlled at 100m / min, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com