Functionalized graphene oxide enhanced benzoxazine-based composite resin and preparation method thereof

A technology of benzoxazine and composite resin, which is applied in the field of polymer materials, can solve the problems of small interaction between nanoparticles and resin, low crosslinking density of composite resin, and lower resin curing temperature, so as to improve processing performance and physical properties, Effect of improving heat resistance and increasing glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Preparation of carboxylated graphene oxide:

[0035] Using natural flake graphite with a particle size of 50 μm as a raw material, graphite oxide was obtained through an improved Hummers method, wherein the improved Hummers method was to add natural flake graphite to a sulfuric acid / phosphoric acid mixed solution with a volume ratio of 9:1, stir, add Potassium permanganate; specifically: by mass %, natural flake graphite accounts for 3, sulfuric acid / phosphoric acid mixture accounts for 85, and potassium permanganate accounts for 12; control the reaction system temperature below 10°C in an ice-water bath, and heat up after 60 minutes of reaction Reaction at 40°C for 20 hours; the reaction product was washed by centrifugation until there was no sulfate ion, and then dried at 60°C to obtain graphite oxide.

[0036] Then chemically modify graphite oxide by chloroacetic acid method to obtain carboxylated graphene oxide: first add graphite oxide to deionized water and ultras...

Embodiment 1

[0041] Preparation of carboxylated graphene-reinforced benzoxazine / phenolic binary nanocomposite resin:

[0042] According to the mass % ratio, 1% carboxylated graphene oxide and 99% bisphenol A benzoxazine monomer (molecular formula C 22 h 3 0N 2 o 2 , molecular weight 354) / first-stage phenolic resin (phenol source is phenol, cresol, xylenol) prepolymer mixture is blended and intercalated in a high-speed planetary ball mill, wherein the bisphenol A benzoxazine monomer The mass ratio of bisphenol A benzoxazine monomer to the first-stage phenolic resin prepolymer in the first-stage phenolic resin prepolymer is 6:4. The specific process is to first ball mill the mixture at 400rpm for 3 hours, and then at 500rpm for 1 hour. During this process, the high-speed planetary ball mill runs continuously for 20 minutes and stops for 5 minutes.

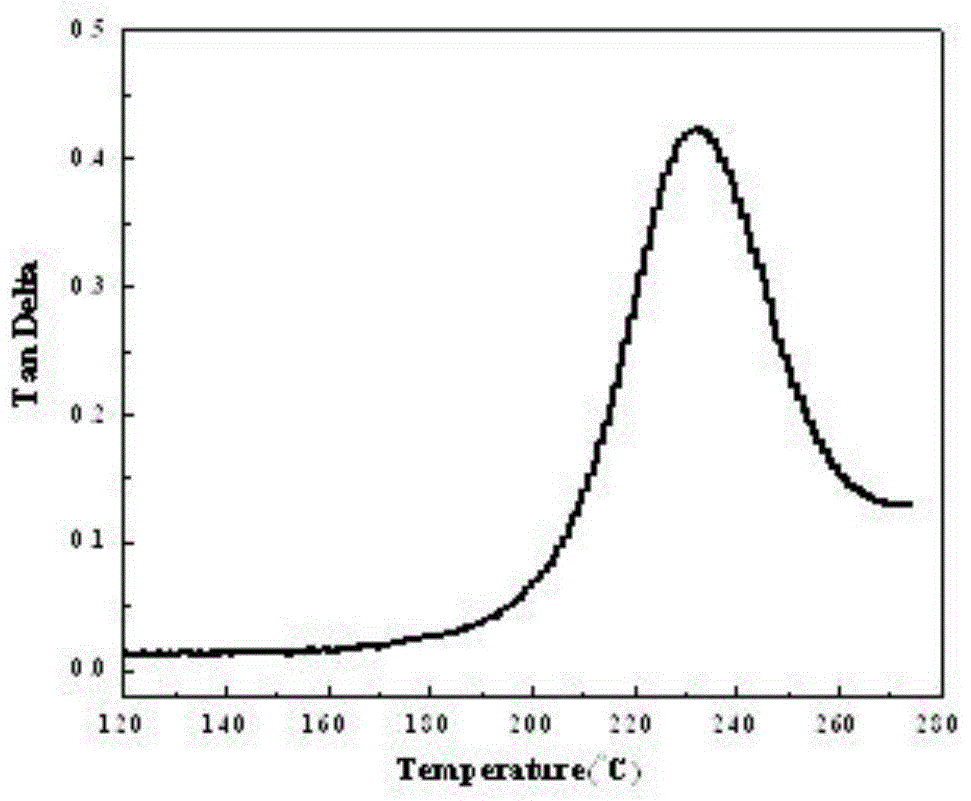

[0043] The obtained mixed sample was vacuum degassed at 80°C for 2h to remove air bubbles, and then cured at 220°C for 6h to obtain carboxyl...

Embodiment 2

[0046] Preparation of aminated graphene-reinforced benzoxazine / phenolic binary nanocomposite resin:

[0047] According to the mass % ratio, 1% aminated graphene oxide and 97% bisphenol F benzoxazine monomer (molecular formula C 30 h 30 N 2 o 2 , molecular weight 450) / secondary phenolic resin (phenol source is phenol) prepolymer mixture for blending, intercalation, wherein bisphenol F benzoxazine monomer / secondary phenolic resin prepolymer bisphenol F benzene The mass ratio of oxazine monomer to the second-order phenolic resin prepolymer is 7:3. The specific process is to ball mill the mixture at 400rpm for 3 hours, and then at 500rpm for 1 hour. During this process, the high-speed planetary ball mill continues to run for 20 minutes. Turn for 5 minutes.

[0048] The mixed sample was vacuumed and degassed at 100°C for 1 hour to remove air bubbles, and then cured at 200°C for 8 hours to obtain an aminated graphene oxide reinforced benzoxazine / phenolic binary nanocomposite res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com