Energy-saving and environment-friendly corrugated board production technique

A corrugated cardboard, energy saving and environmental protection technology, applied in the field of papermaking, can solve the problems of poor damage resistance, low strength, not easy to stack, etc., and achieve the effects of increasing curing rate, improving production efficiency, and environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

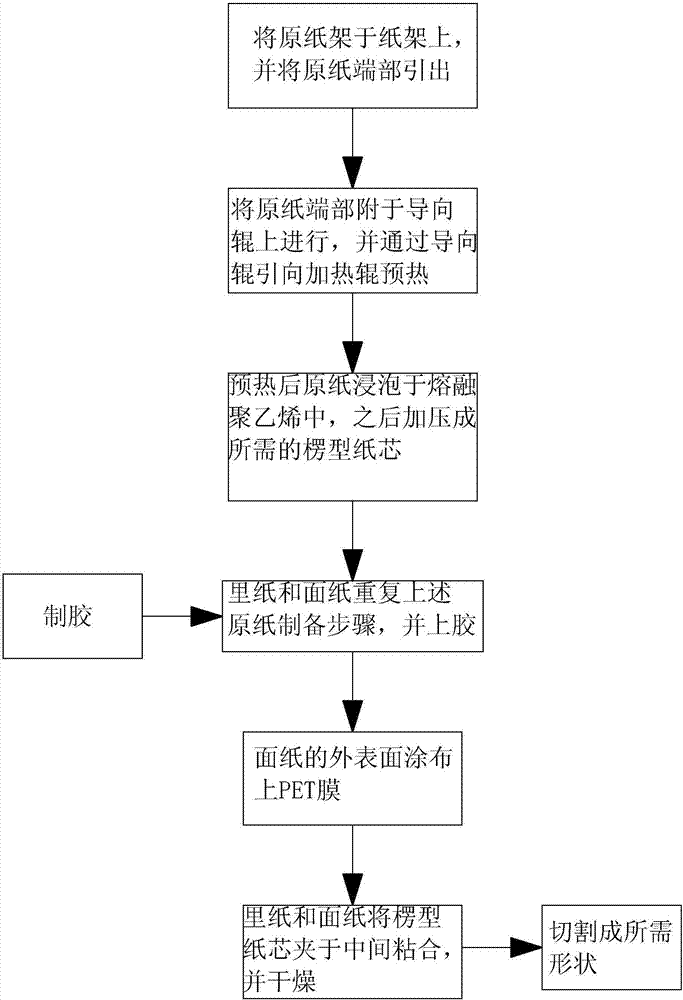

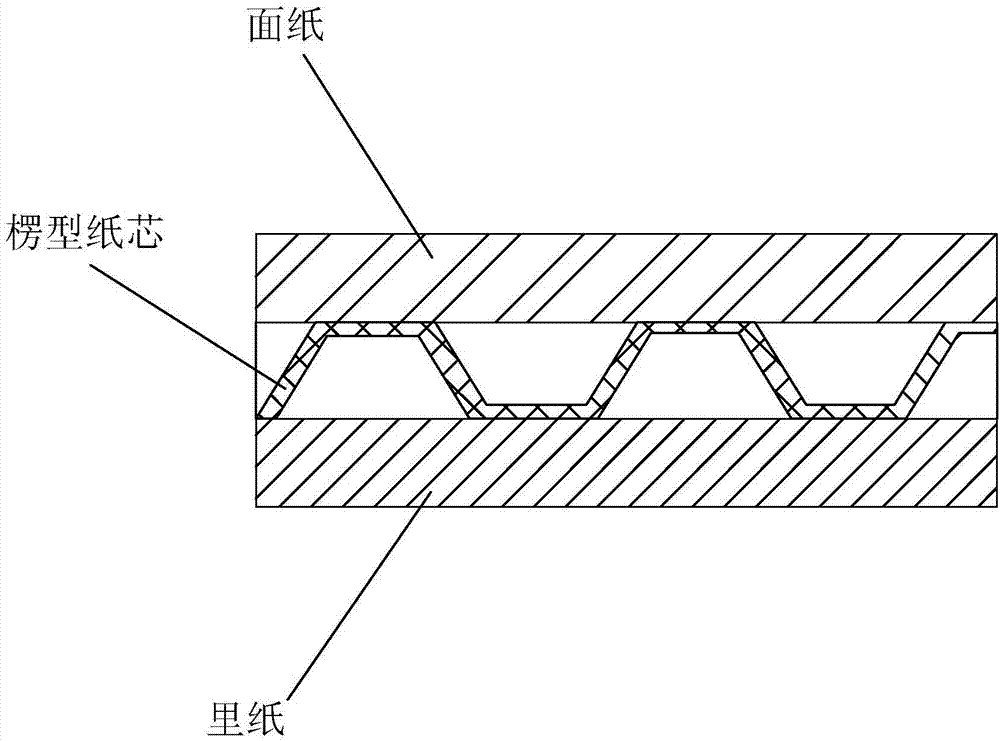

[0045] An energy-saving and environment-friendly corrugated cardboard production process, comprising the following steps:

[0046] S1 glue making:

[0047] a. Add 200Kg of water to barrel A of the glue making barrel, and add 50Kg of water to barrel B;

[0048] b. Add 30Kg of corn flour, 20Kg of bentonite, 10Kg of borax, 5Kg of sodium dodecylbenzenesulfonate, 6Kg of carbonamide, 20Kg of modified polyvinyl alcohol, 5Kg of polyether silicone defoamer, and isothiazole into barrel A. 6Kg of ketone, 40Kg of acrylic acid and 10Kg of water-based epoxy resin, and stir at a speed of 500-800rpm to fully mix to obtain a glue;

[0049] c. Add 10Kg of epoxy curing agent to barrel B, and stir at a speed of 500-700rpm to fully dilute the epoxy curing agent;

[0050]d. According to the required amount, mix the glue solution in barrel A and the epoxy curing agent solution in barrel B at a weight ratio of 12:1 to make the required adhesive;

[0051] S2 Install the paper tube of the base paper...

Embodiment 2

[0059] An energy-saving and environment-friendly corrugated cardboard production process, comprising the following steps:

[0060] S1 glue making:

[0061] a. Add 300Kg of water to barrel A of the glue making barrel, and add 80Kg of water to barrel B;

[0062] b. Add 50Kg of corn flour, 40Kg of bentonite, 20Kg of borax, 13Kg of sodium dodecylbenzenesulfonate, 14Kg of carbonamide, 30Kg of modified polyvinyl alcohol, 8Kg of polyether silicone defoamer, and isothiazole into barrel A. 10Kg of ketone, 60Kg of acrylic acid and 20Kg of water-based epoxy resin, and stir at a speed of 500-800rpm to fully mix to obtain a glue;

[0063] c. Add 18Kg of epoxy curing agent to barrel B, and stir at a speed of 500-700rpm to fully dilute the epoxy curing agent;

[0064] d. According to the required amount, mix the glue solution in barrel A and the epoxy curing agent solution in barrel B at a weight ratio of 12:1 to make the required adhesive;

[0065] S2 Install the paper tube of the base p...

Embodiment 3

[0073] An energy-saving and environment-friendly corrugated cardboard production process, comprising the following steps:

[0074] S1 glue making:

[0075] a. Add 250Kg of water to barrel A of the glue making barrel, and add 65Kg of water to barrel B;

[0076] b. Add 40Kg of corn flour, 30Kg of bentonite, 15Kg of borax, 9Kg of sodium dodecylbenzenesulfonate, 10Kg of carbonamide, 25Kg of modified polyvinyl alcohol, 6.5Kg of polyether silicone defoamer, 8Kg of thiazolinone, 50Kg of acrylic acid and 15Kg of water-based epoxy resin are stirred and mixed at a speed of 500-800rpm to obtain glue;

[0077] c. Add 14Kg of epoxy curing agent to barrel B, and stir at a speed of 500-700rpm to fully dilute the epoxy curing agent;

[0078] d. According to the required amount, mix the glue solution in barrel A and the epoxy curing agent solution in barrel B at a weight ratio of 12:1 to make the required adhesive;

[0079] S2 Install the paper tube of the base paper on the paper holder, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com