Spraying type ultraviolet cured woodware varnish

A clear topcoat and ultraviolet light technology, applied in the direction of coating, etc., can solve the problems of cracking of the coating film, improper use of additives, and high viscosity, and achieve the effect of avoiding cracking and preventing stress accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

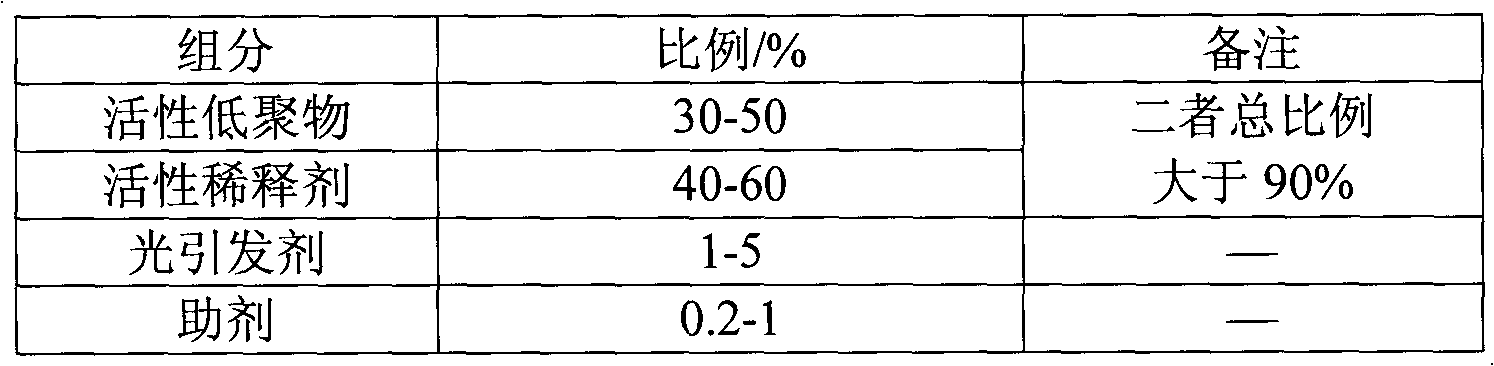

Method used

Image

Examples

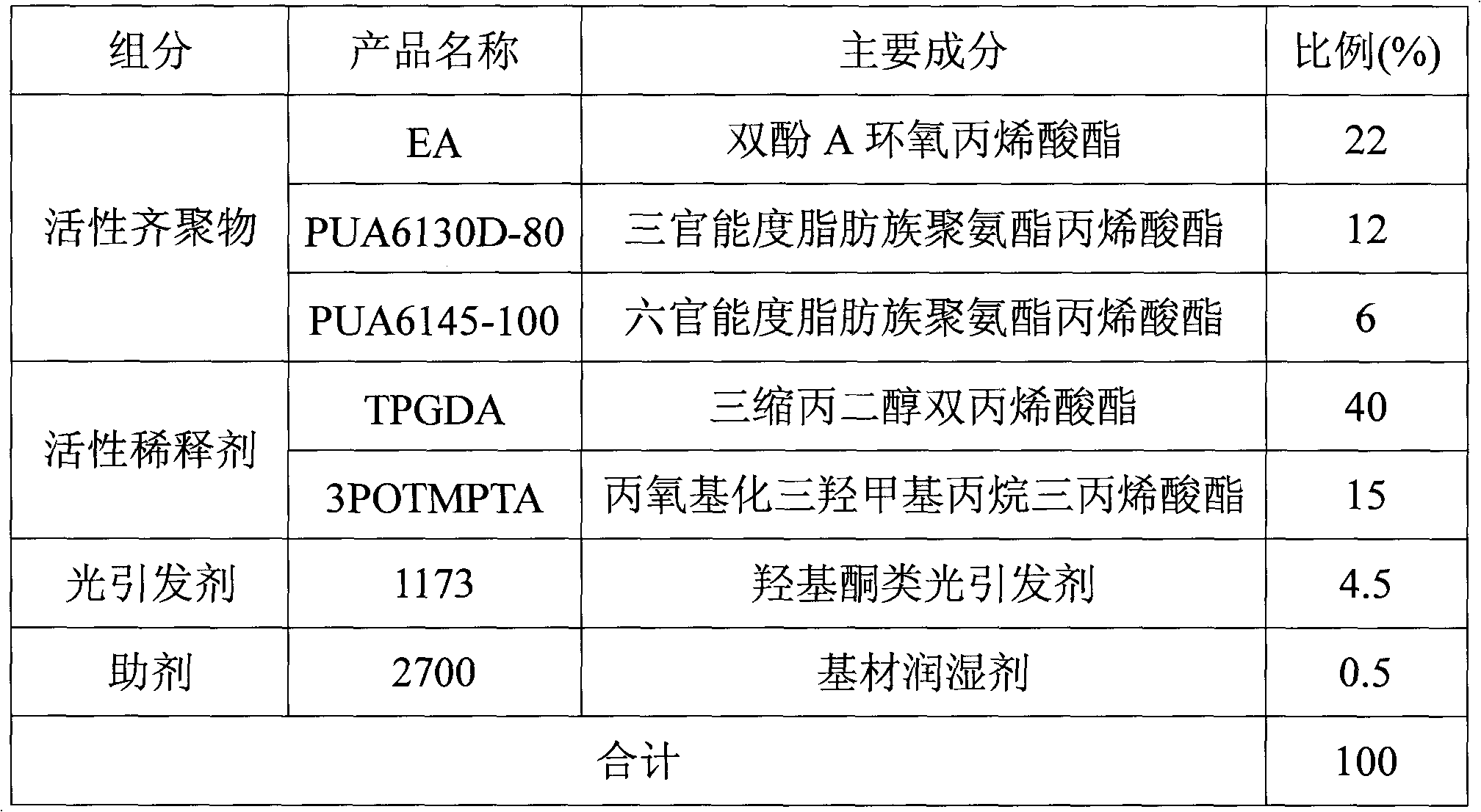

Embodiment 1

[0050] Each component of table 4 embodiment 1 and its weight percentage content table

[0051]

[0052]Prepare 100g photocurable coating according to the formula shown in Table 4: get 22g bisphenol A epoxy acrylate, 12g trifunctionality aliphatic urethane acrylate, 6g hexafunctionality aliphatic urethane acrylate and mix, add 40g tripropylene glycol under stirring Diacrylate, 15g propoxylated trimethylolpropane triacrylate, 2.5g 1173 hydroxyketone photoinitiator, 2g 184 hydroxyketone photoinitiator, 0.25g 2700 substrate wetting agent and 0.25g 432 substrate wetting agent , to obtain UV-curable coatings.

[0053] The active oligomer includes bisphenol A epoxy acrylate with an acid value of 10-25 mgKOH / g.

[0054] Bisphenol A epoxy acrylate, trifunctional aliphatic urethane acrylate and hexafunctional aliphatic urethane acrylate are selected from the corresponding industrial grade products of Sartomer Company in the United States, and the code names are CN104, CN970A60 and C...

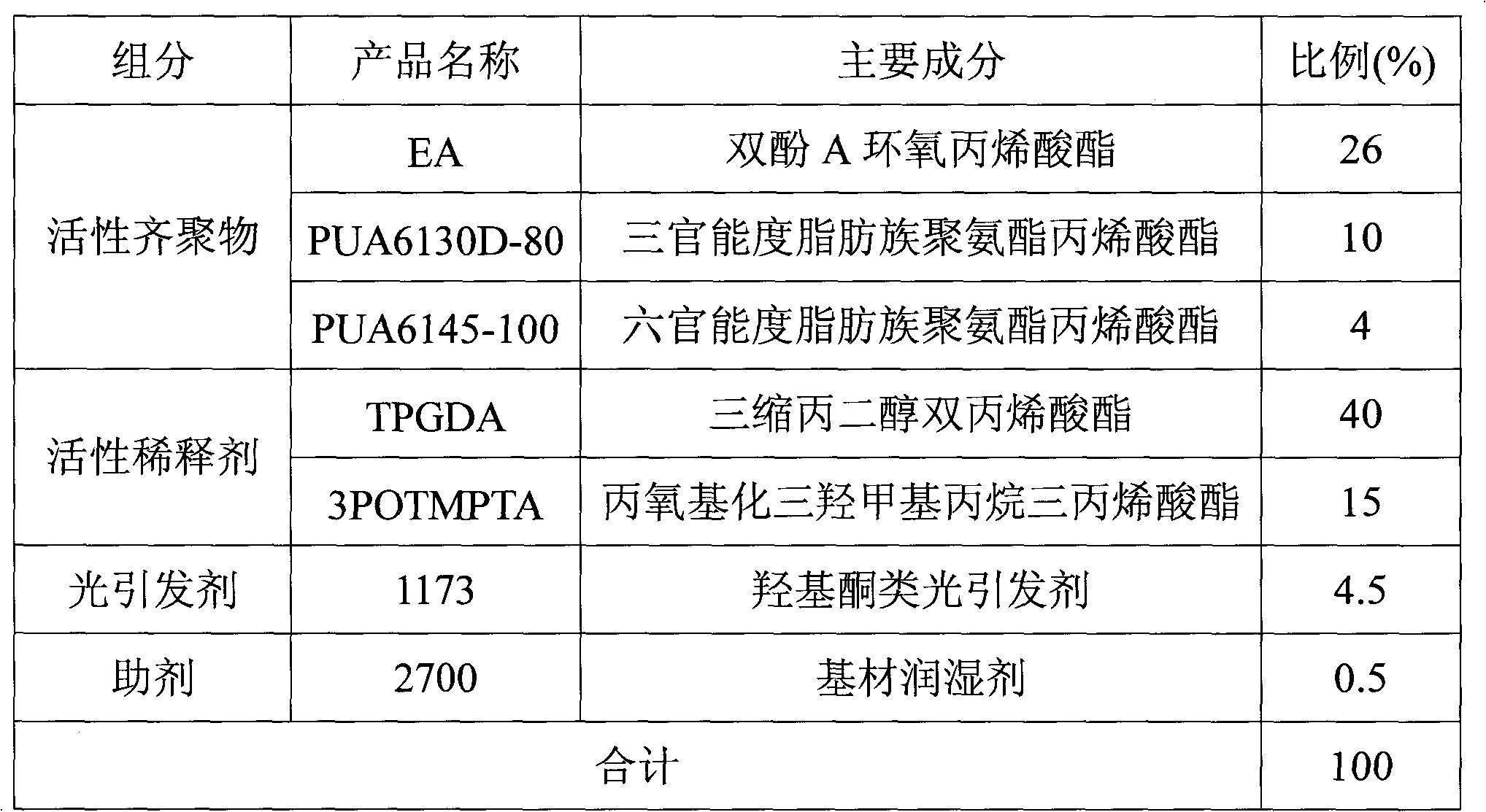

Embodiment 2

[0059] What is different from Example 1 is that the ratio of each component changes, specifically as follows:

[0060] Each component of table 5 embodiment 2 and its weight percentage content table

[0061]

Embodiment 3

[0063] What is different from Example 1 is that the ratio of each component changes, specifically as follows:

[0064] Each component of table 6 embodiment 3 and its weight percentage content table

[0065]

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com