Ultraviolet-cured weather-proof self-cleaning coating composition

A self-cleaning, ultraviolet light technology, used in polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc. Diversified coating process, fast curing rate and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

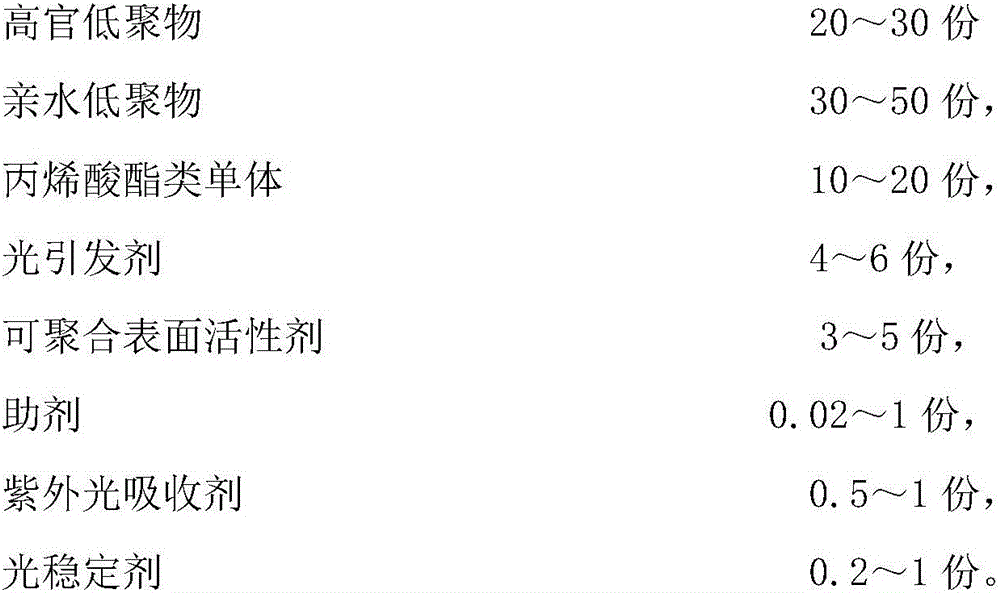

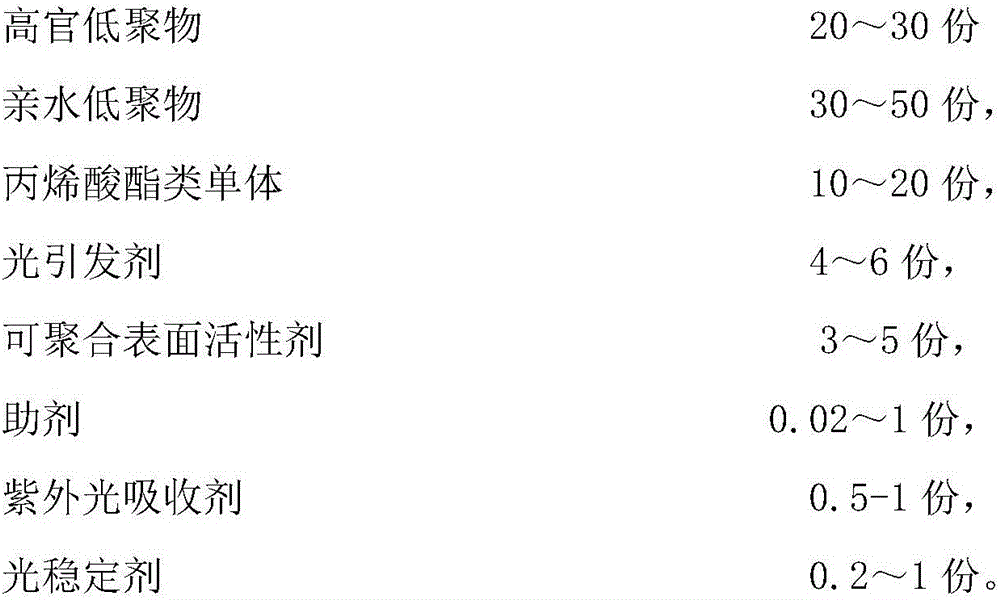

Method used

Image

Examples

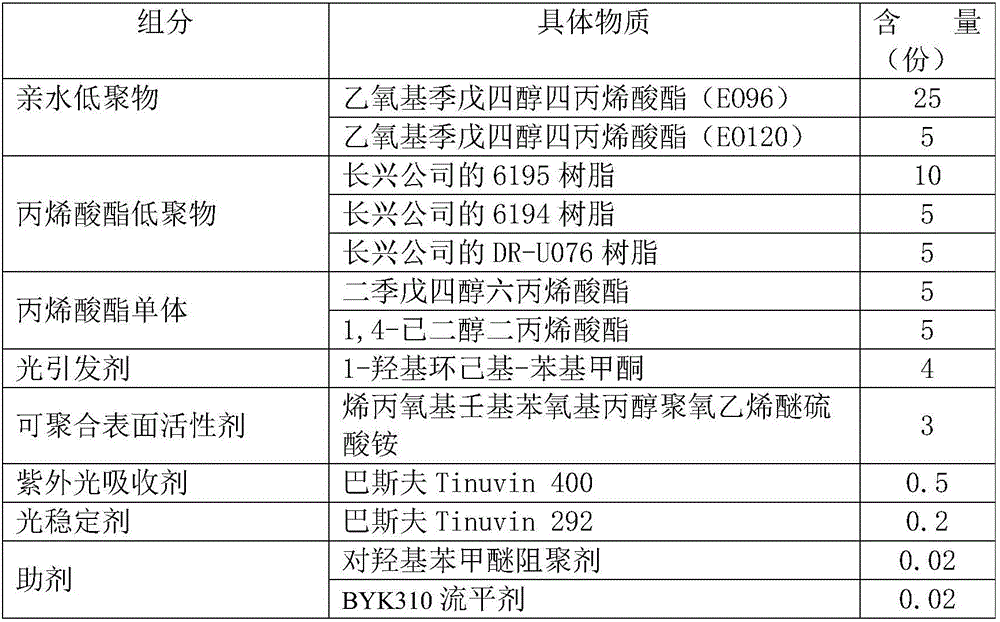

Embodiment 1

[0045] The present embodiment 1 relates to a kind of UV curable coating composition with weather resistance and self-cleaning effect, comprises each component of the parts by weight shown in Table 1; Get each component by weight parts, after each component Mix evenly, dilute the coating prepared above with an organic solvent (a mixed solution of ethyl acetate, butyl acetate, and n-butanol with a mass ratio of 1:2:3) at a mass ratio of 1:2.5, and place it on a PC board Spraying, baking at 45°C for 4 minutes, and then UV curing, the curing energy is 500mJ / cm 2 .

[0046] Table 1

[0047]

[0048] The conventional paint performance, weather resistance performance index and self-cleaning performance of the obtained coating were tested, and the results are shown in Table 4.

Embodiment 2

[0050] This embodiment relates to a UV-curable coating composition with weather resistance and self-cleaning effect, including the components in parts by weight shown in Table 1; Mix, dilute the coating prepared above with an organic solvent (a mixed solution of ethyl acetate, butyl acetate, and n-butanol at a mass ratio of 1:2:3) at a mass ratio of 1:2.5, and carry out the process on a PC board. Spray coating, bake at 45°C for 4 minutes, then UV light curing, the curing energy is 500mJ / cm 2 .

[0051] Table 2

[0052]

[0053] The conventional paint performance, weather resistance performance index and self-cleaning performance of the obtained coating were tested, and the results are shown in Table 4.

Embodiment 3

[0055] This embodiment relates to a UV-curable coating composition with weather resistance and self-cleaning effect, including the components in parts by weight shown in Table 1; Mix, dilute the coating prepared above with an organic solvent (a mixed solution of ethyl acetate, butyl acetate, and n-butanol at a mass ratio of 1:2:3) at a mass ratio of 1:2.5, and carry out the process on a PC board. Spray coating, bake at 45°C for 4 minutes, then UV light curing, the curing energy is 500mJ / cm 2 .

[0056] table 3

[0057]

[0058]

[0059] Performance testing:

[0060] The coatings prepared in Experimental Examples 1 to 3 were tested for performance, and the adhesion, pencil hardness, light transmittance, artificial accelerated aging test, initial water contact angle and sustained water contact angle performance of the coating were measured.

[0061] The specific performance testing items and corresponding methods are as follows:

[0062] 1. Adhesion

[0063] 3M 610 ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com