Thermochromic water-based UV coating and preparation method thereof

A technology of temperature-induced discoloration and temperature-sensitive discoloration, which is applied in the field of coatings, can solve the problems of discoloration materials being easily affected by environmental impurities, increase production costs, increase production processes, etc., and achieve broad application prospects and values, sensitive to temperature changes, and decorative strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

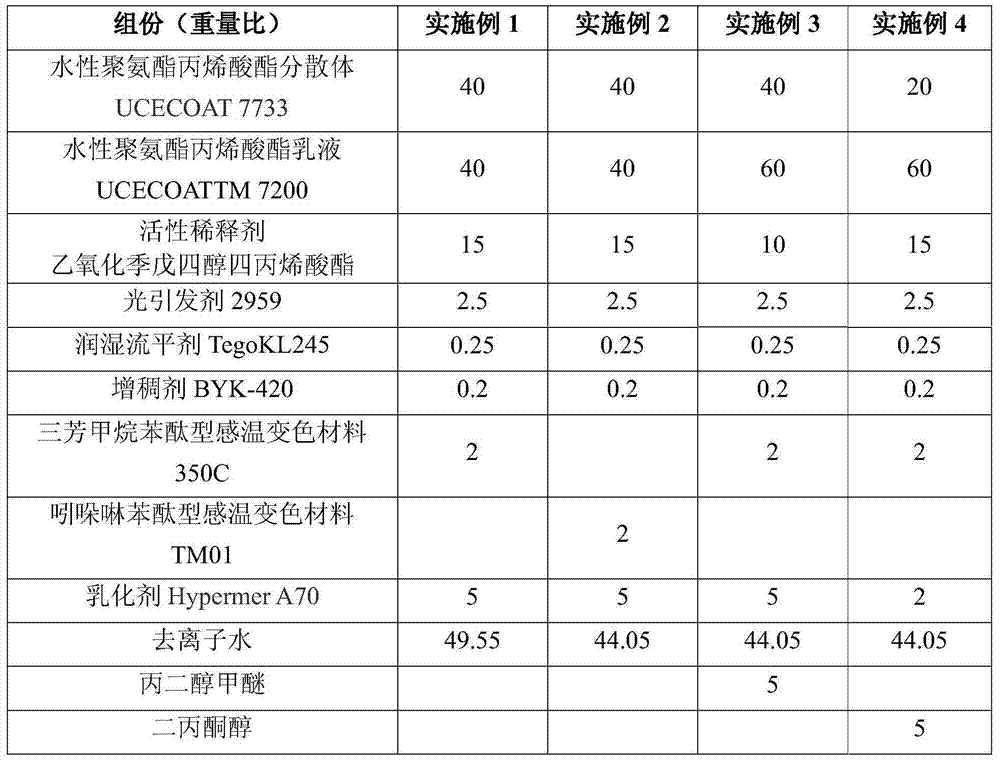

[0033] According to the weight ratio shown in the following tables 1 and 2, respectively prepare thermochromic water-based UV coatings, the specific preparation process is as follows:

[0034] (1) Add the photoinitiator, film-forming aid, and reactive diluent into the stirring tank in sequence, stir at 500-1000r / min for 5-10min, dissolve and mix evenly.

[0035] (2) Under the condition of stirring, add the water-based UV resin into the stirred tank, and stir for 10-15 minutes at the speed of 500-1000r / min. After mixing evenly, add deionized water, defoamer, emulsifier, wetting and leveling agent, thickener and temperature-sensitive color-changing material in sequence, disperse at 1000-3000r / min for 0.5-1h, filter and discharge , to obtain thermochromic water-based UV coatings.

[0036] Table 1

[0037]

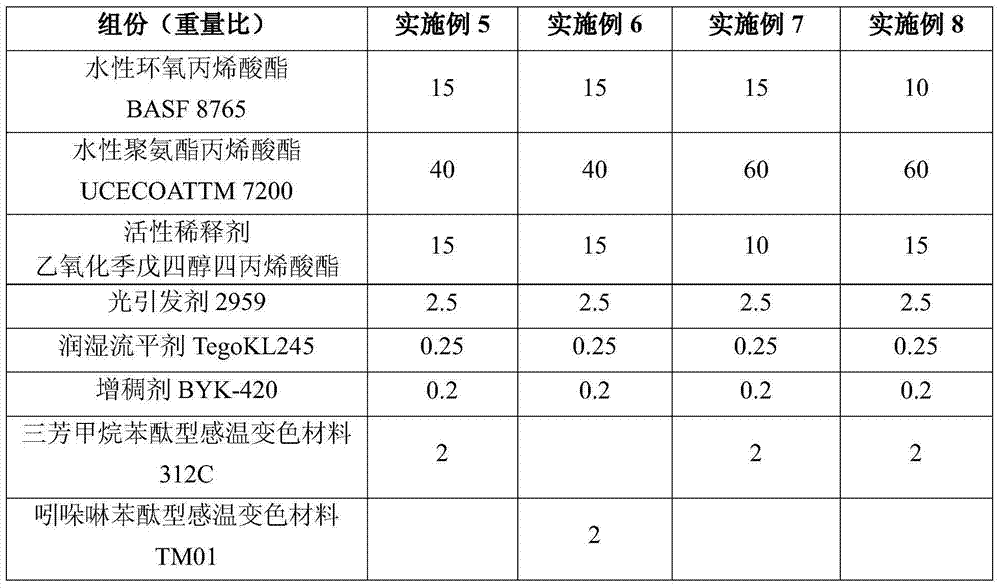

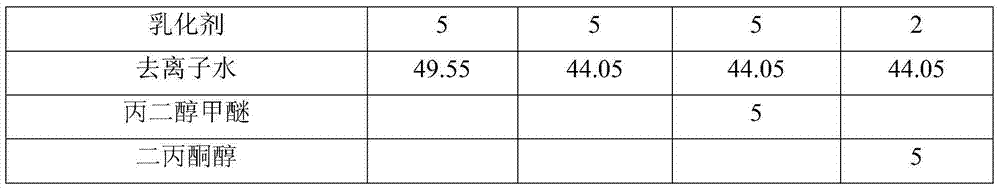

[0038] Table 2

[0039]

[0040]

[0041] The construction technology of above-mentioned coating is as follows:

[0042] After spraying the above paint on the pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com