Method for coating and modifying surface of inorganic paper making fiber calcium sulfate whisker and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

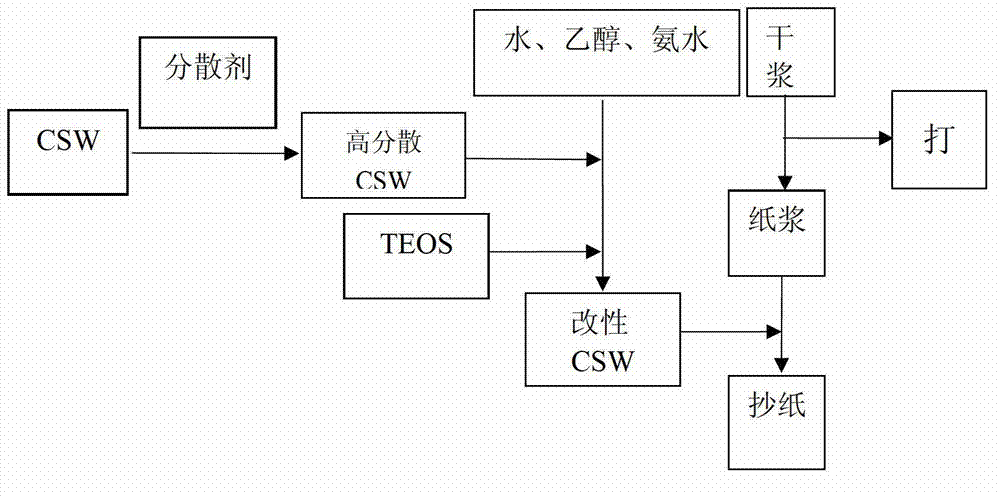

[0033] Embodiment one: see Figure 1 to Figure 6 , the surface coating modification method of the inorganic papermaking fiber calcium sulfate whisker that the present embodiment provides, it comprises the following steps:

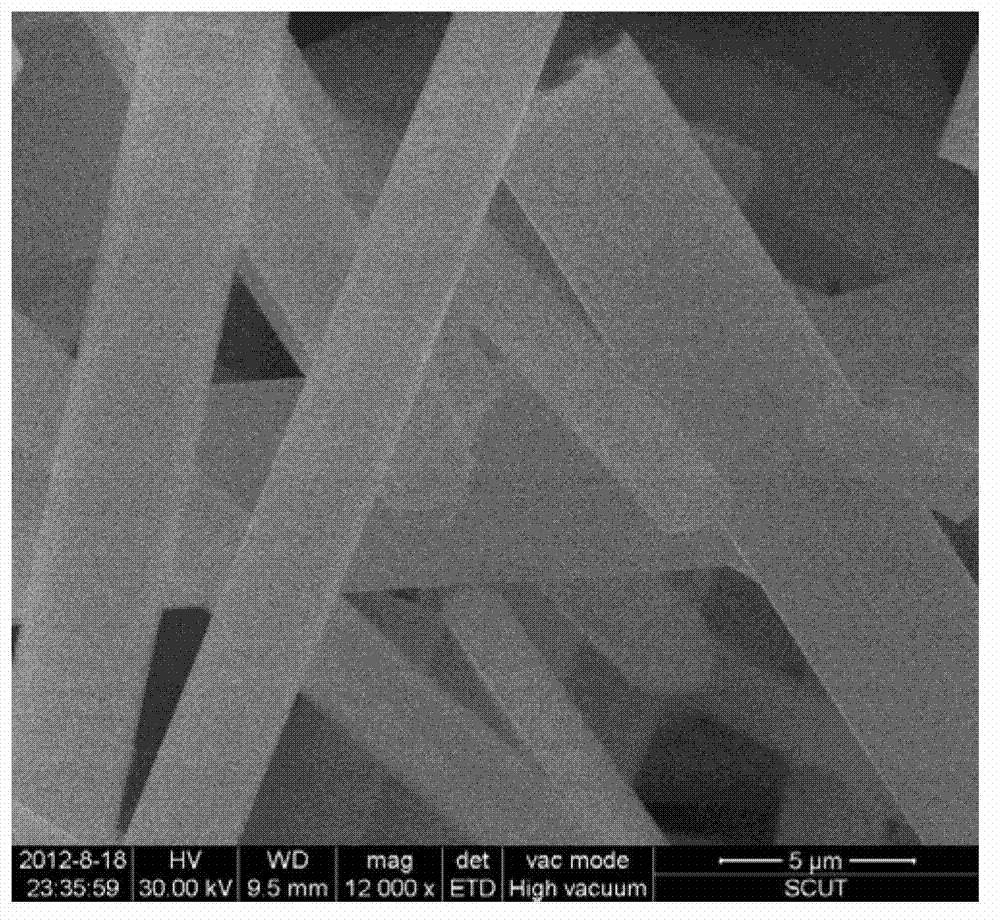

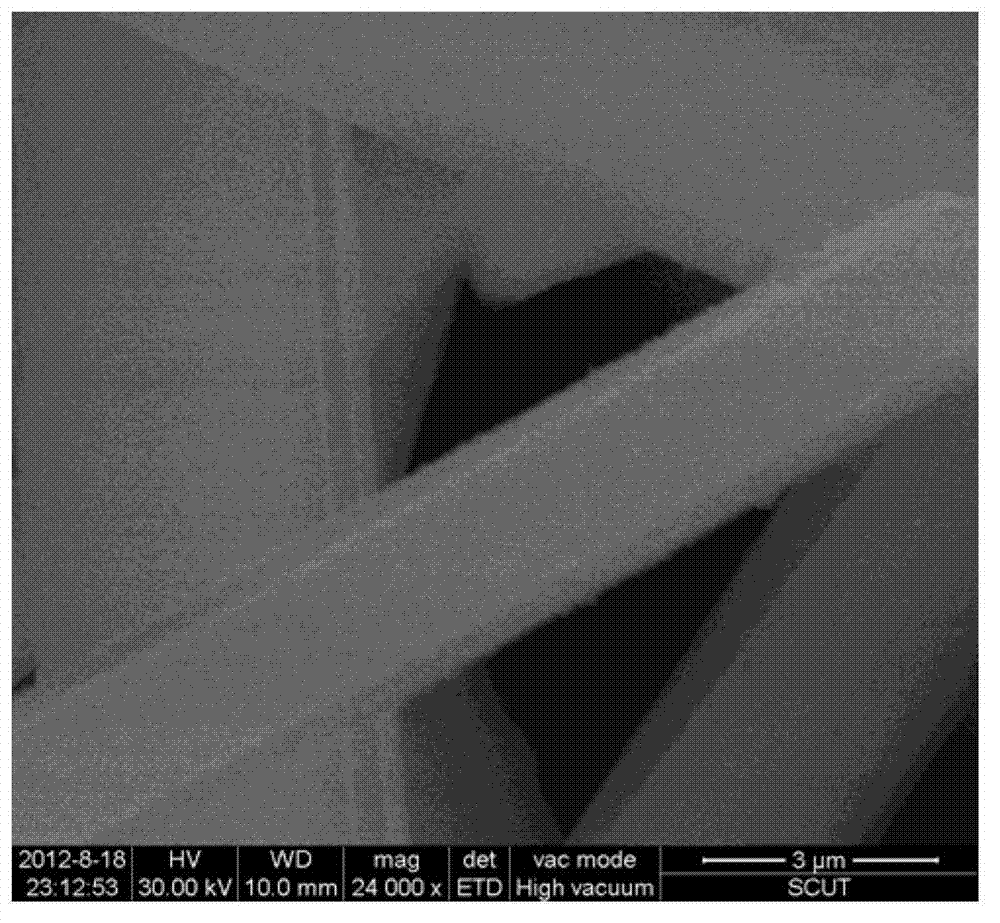

[0034] (1) Disperse the whiskers in an aqueous solution with 5% trisodium citrate relative to the mass fraction of the calcium sulfate whiskers for 2 hours; after processing, filter and dry to obtain highly dispersed calcium sulfate whiskers; figure 2 It is a scanning electron microscope picture of the whiskers after dispersion treatment obtained after the preparation in this step. Table 1 is its energy spectrum analysis table:

[0035] The energy spectrum analysis table of the whiskers after the dispersion treatment in table 1

[0036] Element

Wt%

At%

CK

09.25

15.89

OK

44.40

57.28

01.15

01.03

PK

00.57

00.38

SK

18.99

12.22

CaK

25.65

13.21

...

Embodiment 2

[0047] Embodiment two: the present embodiment provides a kind of surface coating modification method and application of inorganic papermaking fiber calcium sulfate whisker, and it is basically the same as embodiment 1, and its difference is that it also includes the following steps:

[0048] (1) Use a mixed solution of sodium polyphosphate and sodium hexametaphosphate relative to the mass fraction of the calcium sulfate whiskers at 3% to disperse the whiskers in the aqueous solution for 2 hours; after the treatment, filter and dry Obtain highly dispersed calcium sulfate whiskers;

[0049] (2) Measure water, ethanol, ammonia water and ethyl orthosilicate with a volume ratio of 4:8:0.1:1 respectively, and add a small amount of ethanol into the ethyl orthosilicate for dilution; Ethanol and ammonia water are placed in a three-necked flask, and magnetically stirred, then a mixed solution of surfactant sodium dodecylbenzenesulfonate and sodium dodecyl sulfate is added, and the mixtu...

Embodiment 3

[0053] Embodiment three: the present embodiment provides a kind of surface coating modification method and application of inorganic papermaking fiber calcium sulfate whisker, and it is basically the same as embodiment 1, 2, and its difference is, it also comprises the following steps:

[0054] (1) With 3% sodium hexametaphosphate relative to the mass fraction of the calcium sulfate whiskers, the whiskers were dispersed in an aqueous solution for 2 hours; after processing, filter and dry to obtain highly dispersed calcium sulfate whiskers ;

[0055] (2) Measure water, ethanol, ammonia water and ethyl orthosilicate with a volume ratio of 4:8:0.1:1 respectively, and add a small amount of ethanol into the ethyl orthosilicate for dilution; Ammonia water was placed in a three-necked flask, and magnetically stirred, then the surfactant cetyltrimethylammonium bromide was added, and mixed evenly;

[0056] (3) The highly dispersed calcium sulfate whiskers prepared in step (1) are measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com