Catalyst for preparing glycolate through hydrogenating oxalate, preparation method for catalyst and use of catalyst

A glycolic acid ester and oxalic acid ester technology is applied in the preparation of carboxylic acid esters, molecular sieve catalysts, chemical instruments and methods, etc., and can solve the problems of low glycolic acid ester selectivity and poor catalyst activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

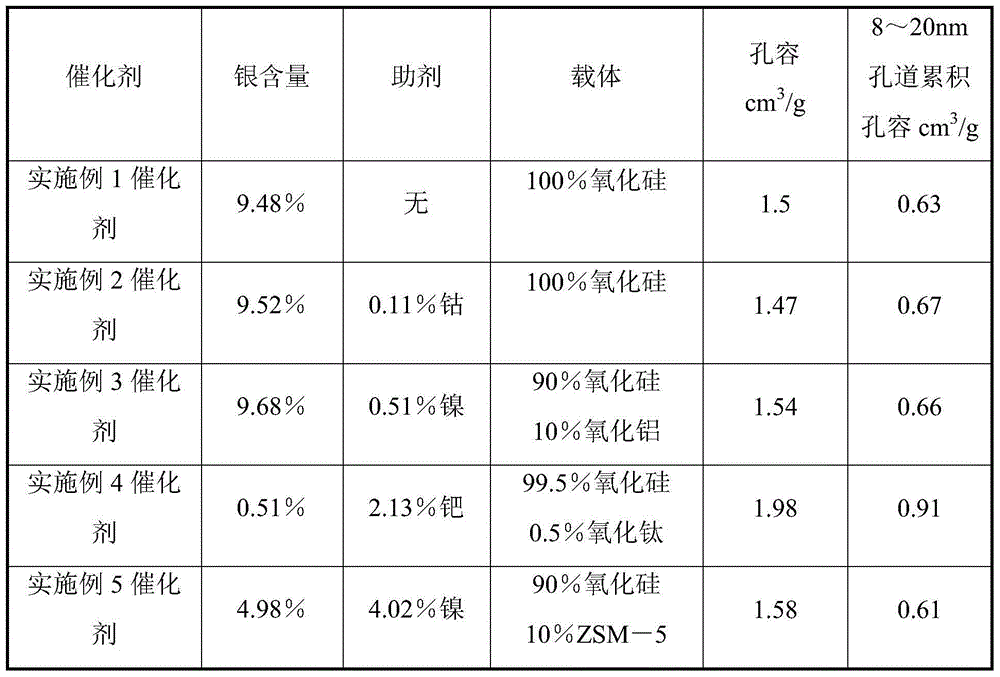

[0037] Prepare 50ml silver acetate solution I containing 4.5% silver, then dissolve 35g P123 in 1.2L aqueous solution containing 1.5mol / L acetic acid, stir well to obtain solution II, then add 75ml tetraethyl orthosilicate dropwise under stirring into solution II to obtain solution III and to obtain slurry IV after stirring for 20 hours. Add the prepared solution I to the slurry IV under stirring, transfer the slurry to the crystallization kettle for aging at 50°C for 12 hours after stirring evenly, after the crystallization is completed, use sodium hydroxide to degrade the pH in the crystallization kettle for 5. Take out the product and filter, then wash the filter cake with ethanol and deionized water, dry at 120°C, and roast at 500°C. Hydrogen glycolate catalyst cat-A1. Catalyst samples were taken for ICP and BET characterization tests, and the test results are shown in Table 1.

Embodiment 2

[0039]Prepare 50ml solution I of silver acetate and cobalt nitrate containing 4.5% silver and 0.045% cobalt, then dissolve 35g P123 in 1.2L aqueous solution containing 1.5mol / L acetic acid, stir well to obtain solution II, and then dissolve 75ml Ethyl orthosilicate was added dropwise to solution II to obtain solution III, and after stirring for 14 hours, slurry IV was obtained. Add the prepared solution I into the slurry IV under stirring, and transfer the slurry to the crystallization tank at 40°C for aging for 12 hours after stirring evenly. After the crystallization is completed, adjust the pH in the crystallization tank with sodium hydroxide to 5. Take out the product and filter, then wash the filter cake with ethanol and deionized water, dry at 120°C, and roast at 500°C. Hydrogen glycolate catalyst cat-A2. Catalyst samples were taken for ICP and BET characterization tests, and the test results are shown in Table 1.

Embodiment 3

[0041] Prepare 50ml solution I of silver acetate and nickel nitrate containing 4.5% silver and 0.22% nickel, then dissolve 35g P123 in 1.2L aqueous solution containing 1.5mol / L acetic acid, stir well to obtain solution II, and then dissolve 69ml Ethyl orthosilicate was added dropwise to solution II to obtain solution III, and then 2 g of alumina was added and stirred for 4 hours to obtain slurry IV. Add the prepared solution I to the slurry IV under stirring, and transfer the slurry to the crystallization tank at 100°C for aging for 12 hours after stirring evenly. . Take out the product and filter, then wash the filter cake with ethanol and deionized water, dry at 120°C, and roast at 500°C. Hydrogen glycolate catalyst cat-A3. Catalyst samples were taken for ICP and BET characterization tests, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com