Biodegradable tissue engineering urethral stent and preparation method thereof

A technology of tissue engineering and urethra, which is applied in the field of urethral stent, can solve the problems of high porosity and low density, achieve the effect of improving toughness, controllable shape and size, and improving the success rate of surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

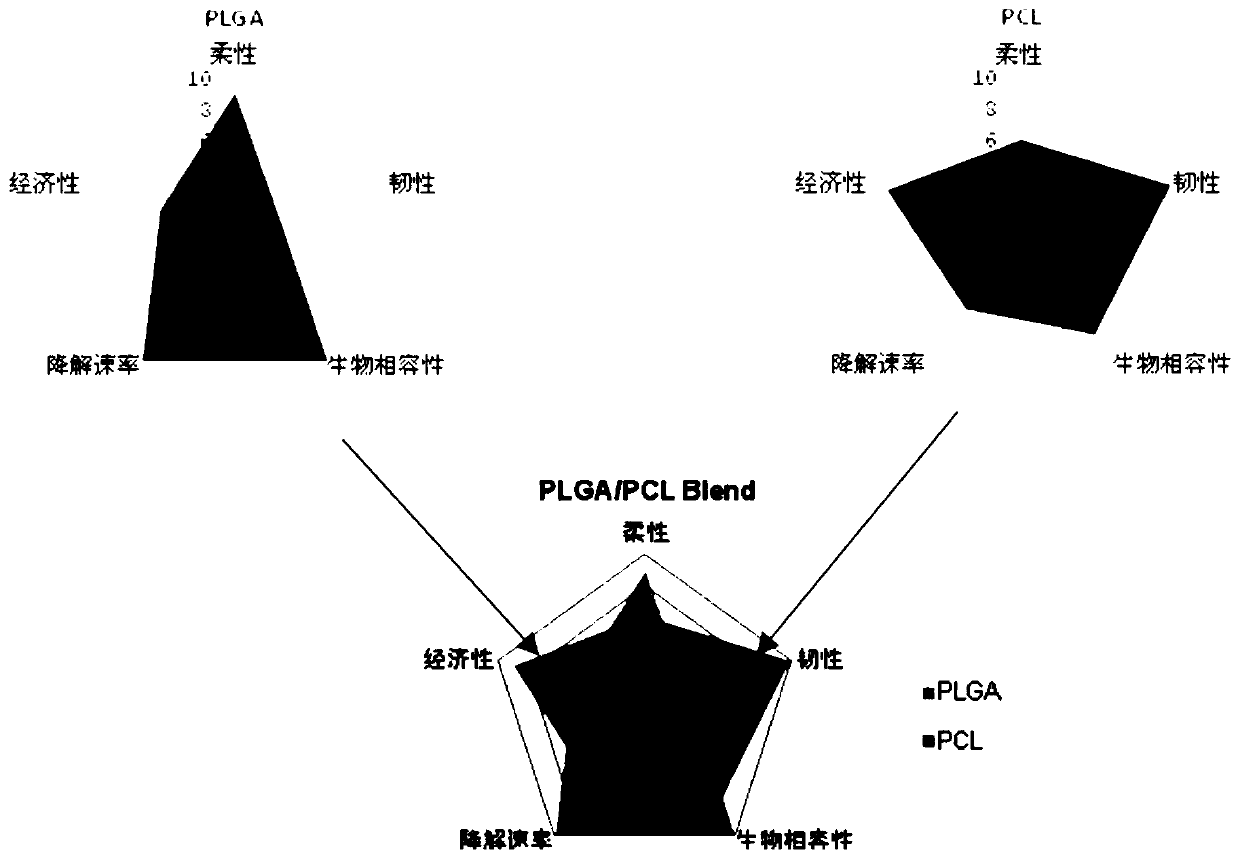

AI Technical Summary

Problems solved by technology

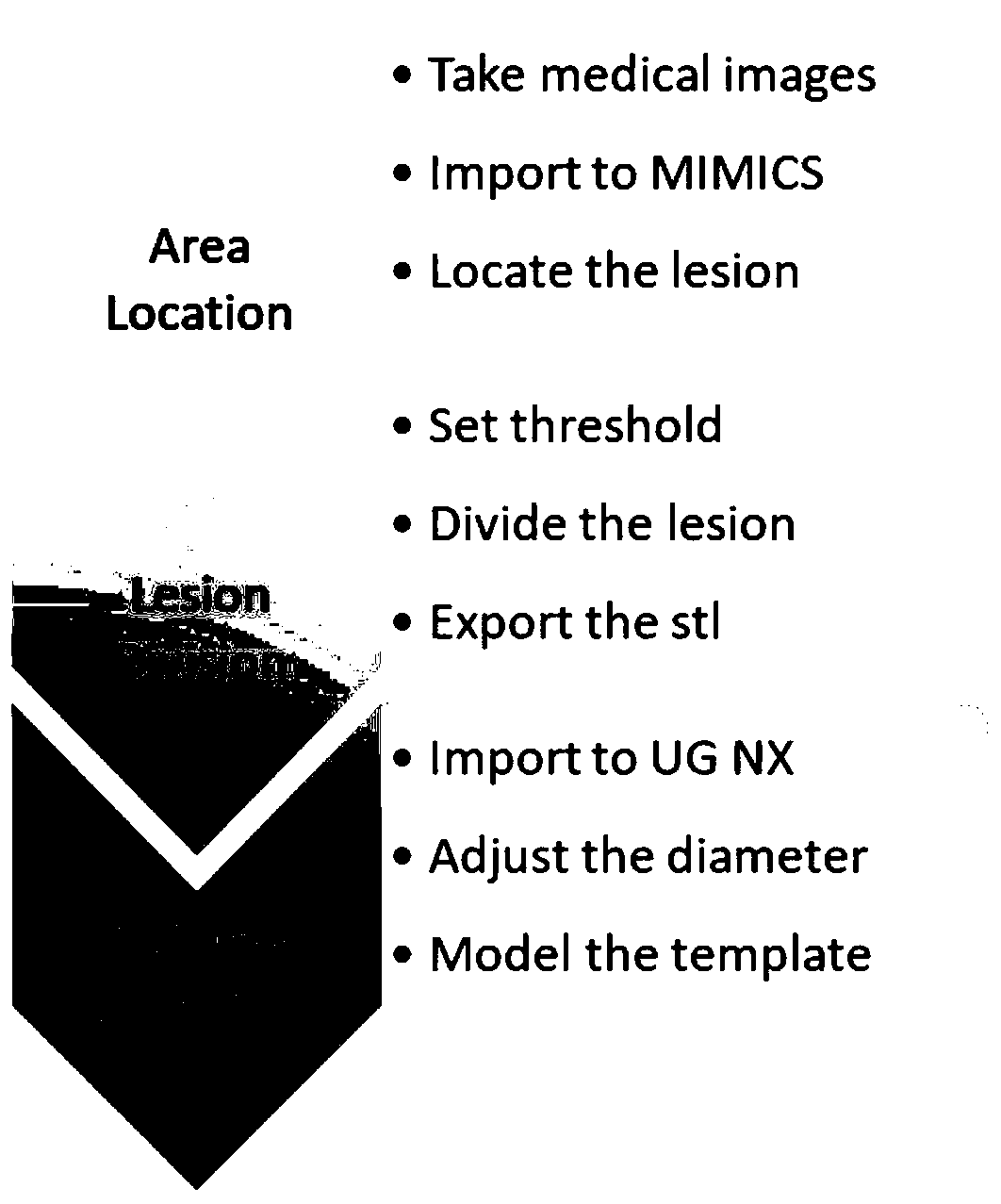

Method used

Image

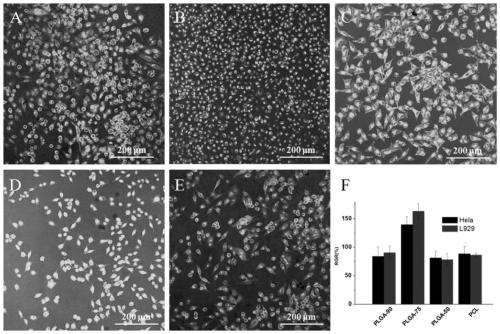

Examples

Embodiment 1

[0040] Example 1, Preparation of PLGA / PCL / TEC (70:30:2) scaffold:

[0041] a) Preparation of modified material solution blending: weigh 10.5g of polylactic acid-co-glycolic acid ester, 4.5g of polycaprolactone, 0.12g of p-toluenesulfonic acid and 0.3g of triethyl citrate (relatively The polymer mass is 2%), heated and stirred at 60°C and dissolved in 80ml of 1,2-dichloroethane. Then the temperature was raised to 110°C and then heated to reflux for 4h. After cooling to room temperature, under vigorous stirring, 180ml of absolute ethanol was slowly added dropwise to produce a large amount of white flocculent precipitate. Then the precipitate was filtered out with suction and rinsed several times with ethanol, and then dried with an infrared lamp to obtain a blend material of PLGA and PCL, which was recorded as PLGA / PCL / TEC 70:30:2. Among them, polylactic acid-co-glycolic acid ester is PLGA-75, a copolymer formed of lactic acid and glycolic acid in a weight ratio of 3:1.

[00...

Embodiment 2

[0045] Example 2, Preparation of PLGA / PCL / TEC (70:30:4) scaffold:

[0046] The content of triethyl citrate is 0.6g (4% relative to the polymer mass), and the others are the same as in Example 1.

Embodiment 3

[0047] Example 3, Preparation of PLGA / PCL / TEC (70:30:6) scaffold:

[0048] The content of triethyl citrate is 0.9g (6% relative to the polymer mass), and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com