Method for preparing glycolate by catalyzing oxalate under action of hydrogenation

A technology of glycolic acid ester and hydrogenation catalysis, which is applied in the preparation of organic compounds, carboxylic acid ester preparation, chemical instruments and methods, etc., can solve the problems of affecting economy and low yield of methyl glycolate, and improve the conversion efficiency, high selectivity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

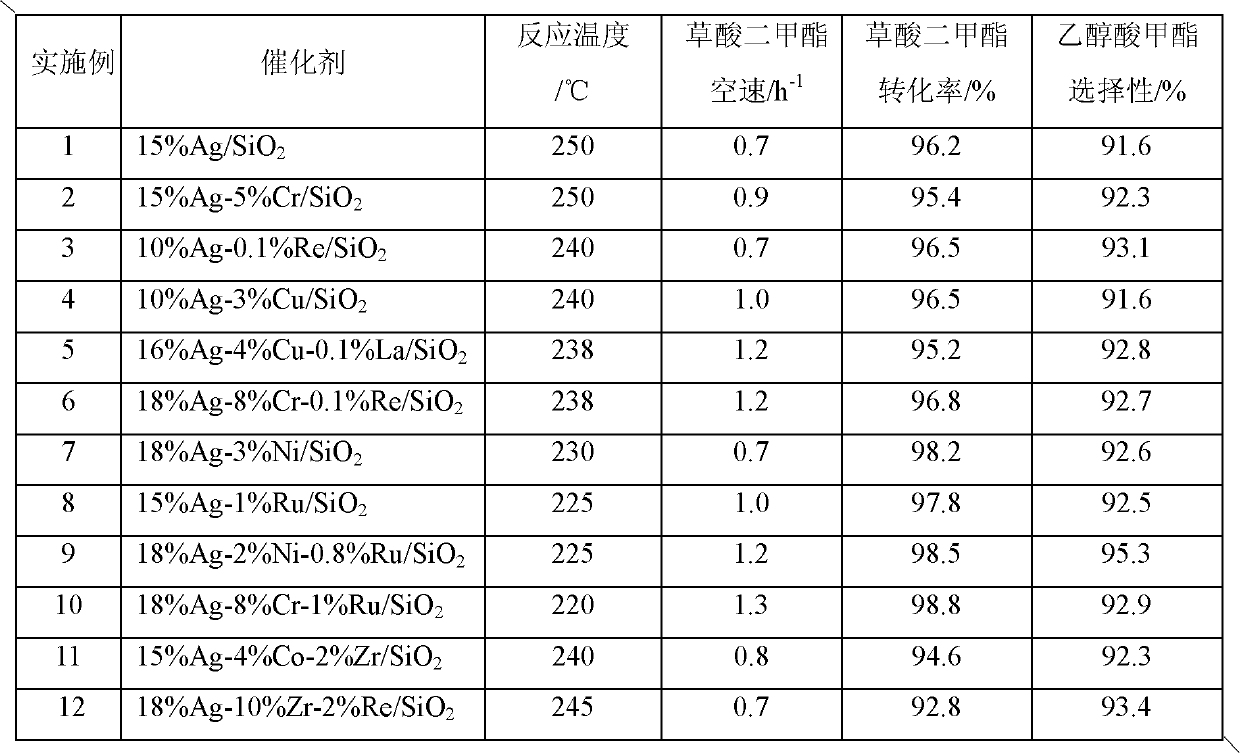

[0018] 100 grams of catalyst (catalyst non-oxygen element composition expressed in mass percent) was loaded into a fixed-bed tubular reactor, reduced with hydrogen at 300 ° C for 4 hours, after the reduction, the temperature was lowered to the reaction temperature, and dimethyl oxalate and hydrogen were mixed After preheating, enter the reactor for reaction, the reaction pressure is 2.5MPa, the molar ratio of dimethyl oxalate / hydrogen is 1:50, the reaction product is analyzed by gas chromatography, and the specific reaction conditions and results are shown in Table 1.

[0019] Table 1

[0020]

Embodiment 13~15

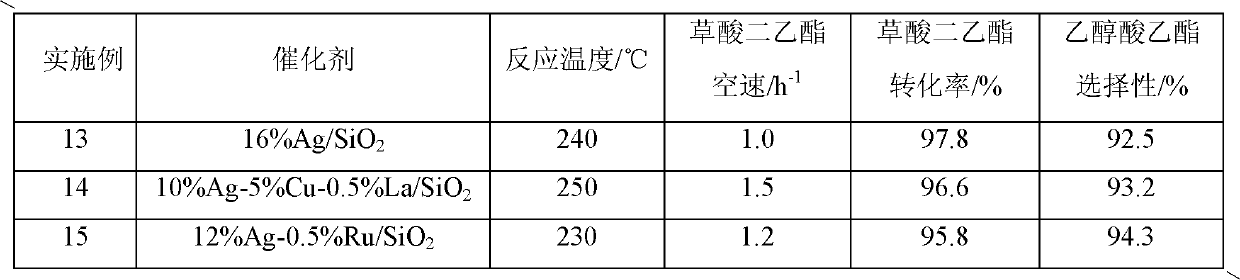

[0022] 100 grams of catalyst (catalyst non-oxygen composition expressed in mass percent) was loaded into a fixed-bed tubular reactor, and reduced with hydrogen at 300°C for 4 hours. After the reduction, the temperature was lowered to the reaction temperature, and diethyl oxalate and hydrogen were mixed Enter reactor reaction after preheating, reaction pressure 2.5MPa, the mol ratio of diethyl oxalate / hydrogen 1: 50, reaction product uses gas chromatography analysis, other reaction conditions and reaction result among the embodiment 13~15 are shown in Table 2.

[0023] Table 2

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com