Preparation method of glycolide

A glycolide and glycolate technology, which is applied in chemical instruments and methods, molecular sieve catalysts, organic chemistry, etc., can solve the problems of catalyst recovery and utilization under harsh conditions for glycolide synthesis, and catalysts that cannot be recycled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a preparation method of glycolide.

[0036] In a specific embodiment provided by the present invention, in the preparation method of glycolide, the gaseous glycolate is subjected to a cyclization reaction under the conditions catalyzed by a titanium-containing molecular sieve to obtain the product glycolide.

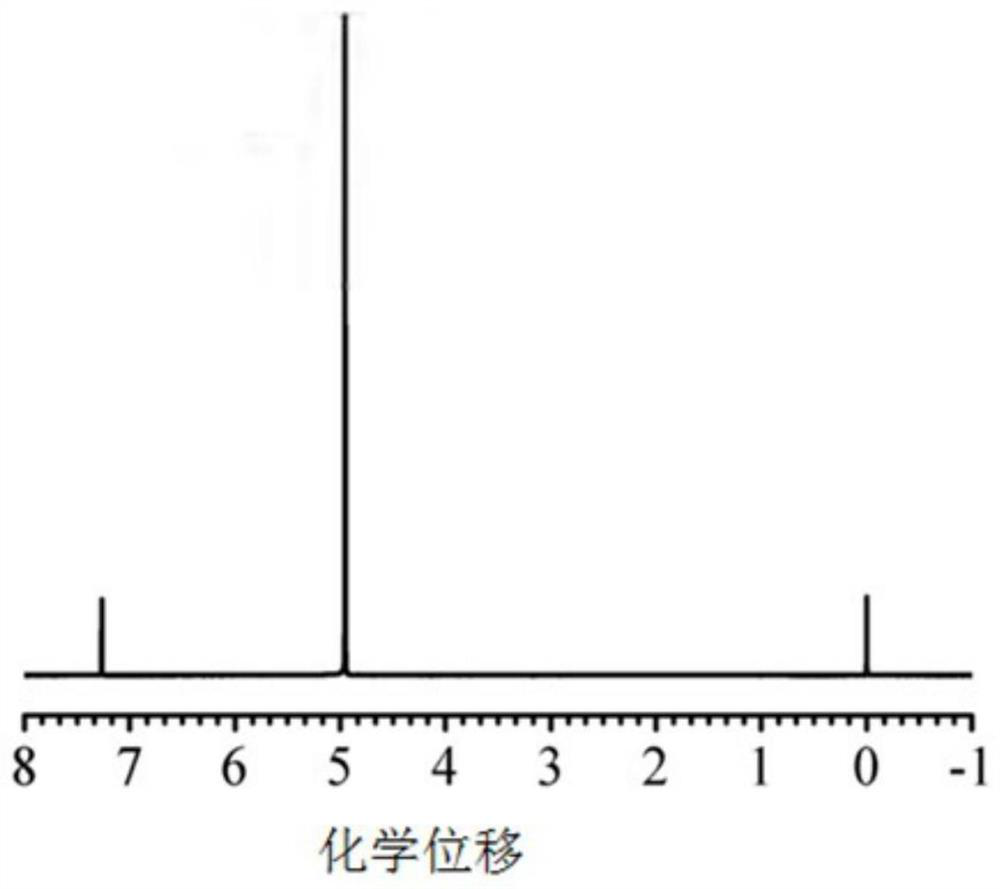

[0037] The reaction formula of glycolate cyclization synthetic glycolide is as follows:

[0038]

[0039] R can be methyl, ethyl, n-propyl, isopropyl, n-butyl.

[0040] In a specific embodiment provided by the present invention, the titanium-containing molecular sieve is a regular structure titanium-containing molecular sieve.

[0041] The titanium-containing molecular sieve with regular structure mentioned in the present invention refers to a titanium-containing molecular sieve with high crystallinity and regular appearance.

[0042] In a specific embodiment provided by the present invention, the titanium-containing molecular sieve is ...

Embodiment 1

[0069] The preparation of embodiment 1 titanium silicon molecular sieve TS-1

[0070] With silica sol (silicon dioxide content is 30wt%) as silicon source, tetrabutyl titanate as titanium source, tetrapropyl ammonium bromide as template, silica sol, tetrabutyl titanate, tetrapropyl ammonium bromide The mass ratio is 91.5:4:4.5, crystallized at 180°C for 30h, filtered, washed, dried and calcined to obtain titanium silicon molecular sieve TS-1 raw powder. Mix 100g of raw powder and 2g of Tianqing powder evenly, add 38g of silica sol and mix evenly, then extrude with extruder, dry the formed sample at 100°C for 12h, and then roast to obtain strip-shaped titanium-silicon molecular sieve TS- 1.

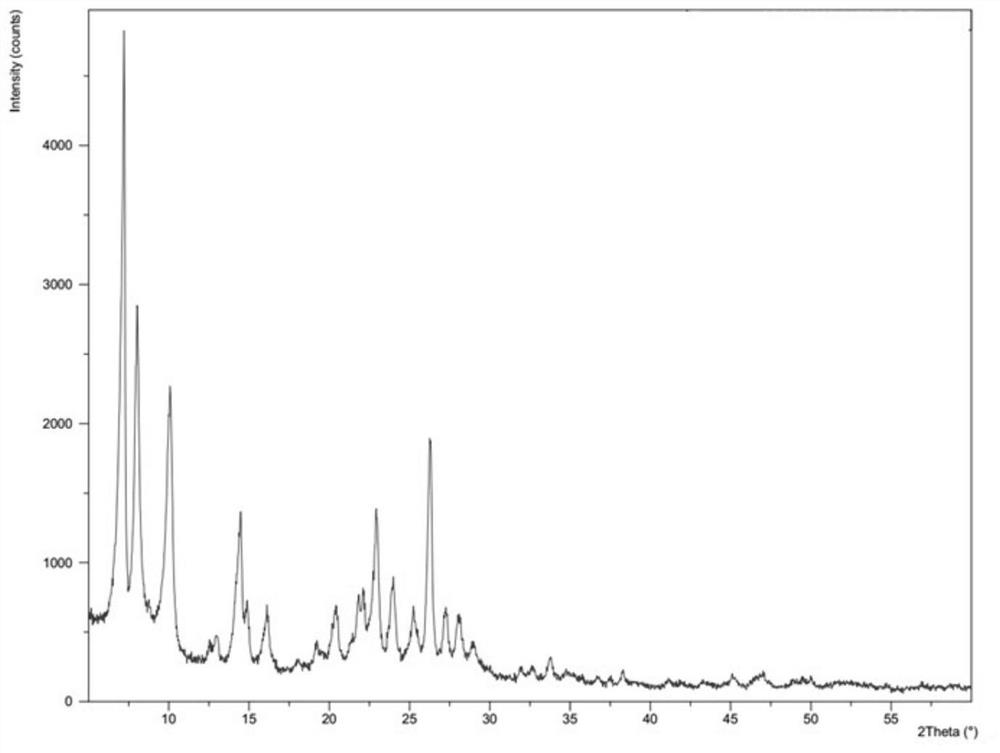

[0071] The XRD spectrum of titanium silicon molecular sieve TS-1 is attached figure 1 , 99% crystallinity.

Embodiment 2

[0072] The preparation of embodiment 2 titanium silicon molecular sieve Ti-MWW

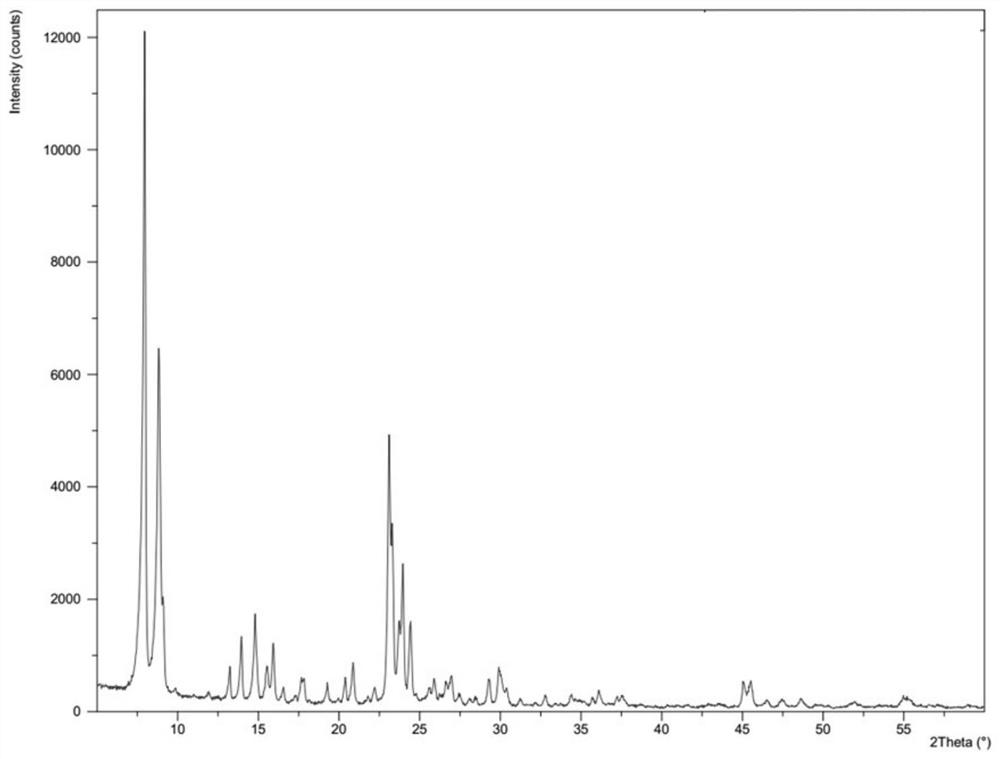

[0073] Using boric acid as the boron source, silica sol (with a silica content of 30wt%) as the silicon source, and piperidine as the template, the mass ratio of boric acid, silica sol, and piperidine is 20:53:27, crystallized at 100°C After 30 hours, B-MWW was obtained after filtration, washing and drying. After the B-MWW was treated with nitric acid with a mass fraction of 33% at 120°C to deboron, the secondary hydrothermal crystallization was performed using tetrabutyl titanate as the titanium source. , crystallized at 160°C for 60 hours, filtered, washed, dried, and roasted to obtain the original titanium-silicon molecular sieve Ti-MWW powder. After mixing 38g of the original powder and 2g of Tianqing powder, add 38g of silica sol and mix evenly before extruding Machine extruded rods were formed, and the formed samples were dried at 100°C for 12 hours and then calcined to obtain strip-shaped t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com