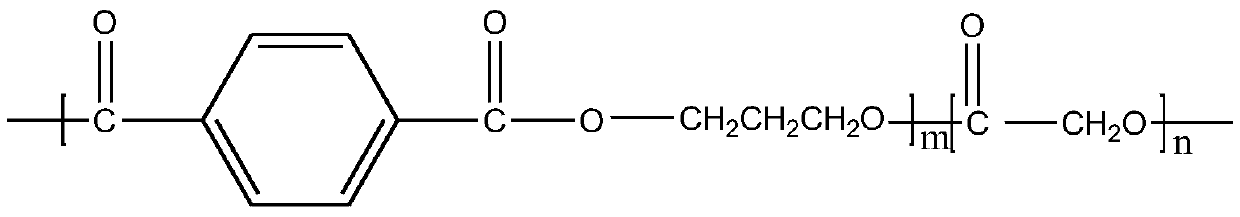

Preparation method of degradable polytrimethylene terephthalate copolyester

A polytrimethylene terephthalate copolyester and terephthalic acid technology, which is applied in the field of degradable copolyester preparation, can solve the problems of white pollution, no biodegradation function, unfavorable environmental sustainable development, and the like, To achieve the effect of reducing content and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] General embodiment: a kind of preparation method of degradable poly(trimethylene terephthalate) copolyester comprises following preparation steps: (1) preparation of low molecular weight polyglycolic acid: glycolic acid and catalyst are placed in reactor, in React at 150-200°C for 3-6 hours, and polymerize to obtain low-molecular-weight polyglycolic acid with a molecular weight of 6000-9000, and the mass ratio of glycolic acid to catalyst is 2000-3000:1;

[0036] (2) Preparation of esterification solution: put terephthalic acid and propylene glycol in a reaction kettle to perform esterification at 220-235°C and 0.1-0.3Mpa for 1-2.5h, and end when the esterification rate reaches above 85%. Prepare esterification liquid, the molar ratio of terephthalic acid and propylene glycol is 1:1.4-1.8;

[0037] (3) Add low-molecular-weight polyglycolic acid to the esterification solution, then add composite catalyst and trimethyl phosphate, and react at 250-260°C and 0.1-0.3Mpa for ...

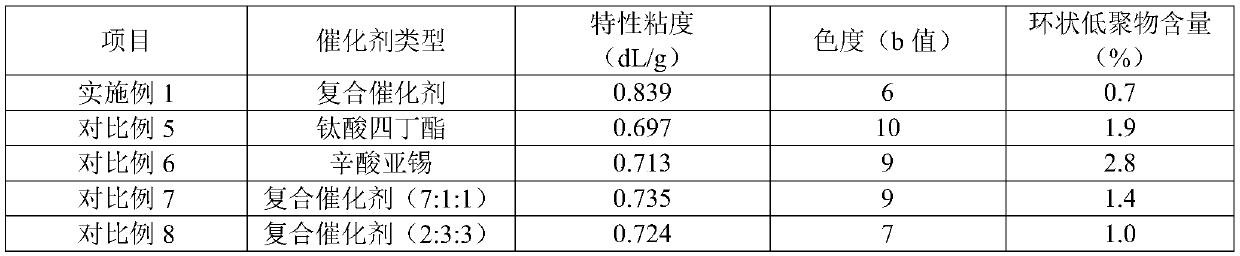

Embodiment 1

[0044] Embodiment 1: a kind of preparation method of degradable polytrimethylene terephthalate copolyester comprises following preparation steps:

[0045] (1) Preparation of low-molecular-weight polyglycolic acid: place glycolic acid and tetrabutyl titanate in a reaction kettle, react at 170°C for 4 hours, and polymerize to obtain low-molecular-weight polyglycolic acid with a molecular weight of 8000, wherein glycolic acid and The mass ratio of catalyst is 2500:1;

[0046] (2) Preparation of esterification solution: place terephthalic acid and propylene glycol in a reaction kettle for esterification at 225° C. and 0.2 Mpa for 2 hours, and end when the esterification rate reaches more than 85%, and prepare esterification solution. The mol ratio of said terephthalic acid and propylene glycol is 1:1.4;

[0047] (3) Low-molecular-weight polyglycolic acid is added to the esterification solution, and the addition is 30% of the total mass of copolyester, and then the composite catal...

Embodiment 2

[0052] Embodiment 2: a kind of preparation method of degradable polytrimethylene terephthalate copolyester comprises the following preparation steps:

[0053] (1) Preparation of low-molecular-weight polyglycolic acid: place glycolic acid and tetrabutyl titanate in a reactor, react at 200°C for 6 hours, and polymerize to obtain low-molecular-weight polyglycolic acid with a molecular weight of 9000, wherein glycolic acid and The mass ratio of catalyst is 2000:1;

[0054] (2) Preparation of esterification solution: place terephthalic acid and propylene glycol in a reaction kettle for esterification at 220° C. and 0.1 Mpa for 1 hour, and end when the esterification rate reaches above 85%, and prepare esterification solution. The mol ratio of said terephthalic acid and propylene glycol is 1:1.4;

[0055] (3) Low-molecular-weight polyglycolic acid is added to the esterification liquid, and the addition is 10% of the total mass of copolyester, and then the composite catalyst (n-tetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com