Hydrolysable non-inflammatory polymer serving as medicament delivery carrier

A transmission carrier and hydrolyzable technology, applied in the direction of non-active components of polymer compounds, etc., to achieve the effect of simple synthesis process, no toxic side effects, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

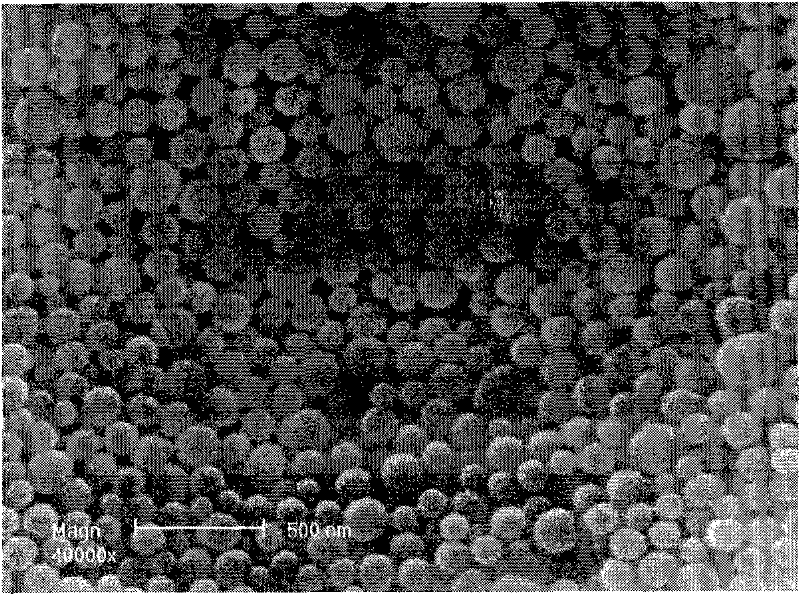

Image

Examples

Embodiment 1

[0017] First, 1.0 mmol of α-cyclodextrin was dissolved in 5 ml of 20% sodium hydroxide aqueous solution, 5 mmol of epichlorohydrin was added thereto, and reacted at 20° C. for 3 hours to obtain α-cyclodextrin polymer; then, under nitrogen protection Dissolve 0.5mmol α-cyclodextrin polymer in 10ml N,N-dimethylformamide, add 0.01mmol pyridine p-toluenesulfonate, and add 10mmol 2,2-dimethoxypropane at 20°C React under magnetic stirring; add 0.2 mmol triethylamine to the reaction system after 3 hours to stop the reaction, precipitate in water and vacuum dry to obtain the target polymer.

Embodiment 2

[0019] Firstly, 1.0 mmol of β-cyclodextrin was dissolved in 10 ml of 15% sodium hydroxide aqueous solution, 7 mmol of epichlorohydrin was added thereto, and reacted at 30°C for 3.5 hours to obtain β-cyclodextrin polymer; then, under nitrogen protection Dissolve 0.5mmol β-cyclodextrin polymer in 15ml N,N-dimethylformamide, add 0.012mmol pyridine p-toluenesulfonate, and add 10mmol 2,2-dimethoxypropane at the same time React under magnetic stirring at 0° C.; add 0.1 mmol triethylamine to the reaction system after 3.5 hours to stop the reaction, precipitate in water and dry in vacuum to obtain the target polymer.

Embodiment 3

[0021] Firstly, 1.0 mmol of γ-cyclodextrin was dissolved in 5 ml of 18% potassium hydroxide aqueous solution, 6 mmol of epichlorohydrin was added thereto, and reacted at 25° C. for 3 hours to obtain a γ-cyclodextrin polymer; then, under nitrogen protection Dissolve 0.5mmol γ-cyclodextrin polymer in 10ml N,N-dimethylacetamide, add 0.01mmol pyridine p-toluenesulfonate, and add 20mmol 2,2-dimethoxypropane at 20 ℃ under magnetic stirring; after 5 hours, 0.1 mmol triethylamine was added to the reaction system to stop the reaction, and the target polymer was obtained by precipitation in water and vacuum drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com