A Method for Improving the Degradability of Hydroxyapatite by Electron Irradiation

A technology of hydroxyapatite and electron irradiation, which is used in material analysis, material excitation analysis, and instrumentation using wave/particle radiation, which can solve the complex experimental process of modification technology, slow degradation rate of hydroxyapatite, and introduction of Heterogeneous ions and other problems, to achieve the effect of large-scale production, significant modification effect, and increase the degree of degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

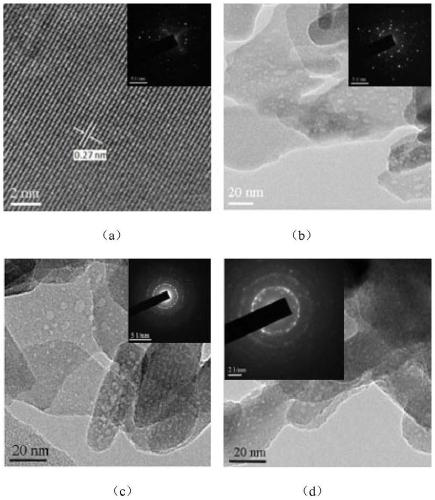

Embodiment 1

[0041] In this embodiment, the method for improving the degradability of apatite by electron irradiation comprises the following steps:

[0042] a. Put the HA powder into a φ13 tableting mold, use a hydraulic tableting machine to apply pressures of 1.5t, 2.0t, and 2.5t respectively and keep the pressure for half a minute. After demoulding, the diameter is 13mm and the height is 1.93mm. , 2.00mm and 2.07mm small wafers. Subsequently, the small discs were placed in a muffle furnace for heat treatment at 400 °C for 1 h to obtain HA block samples.

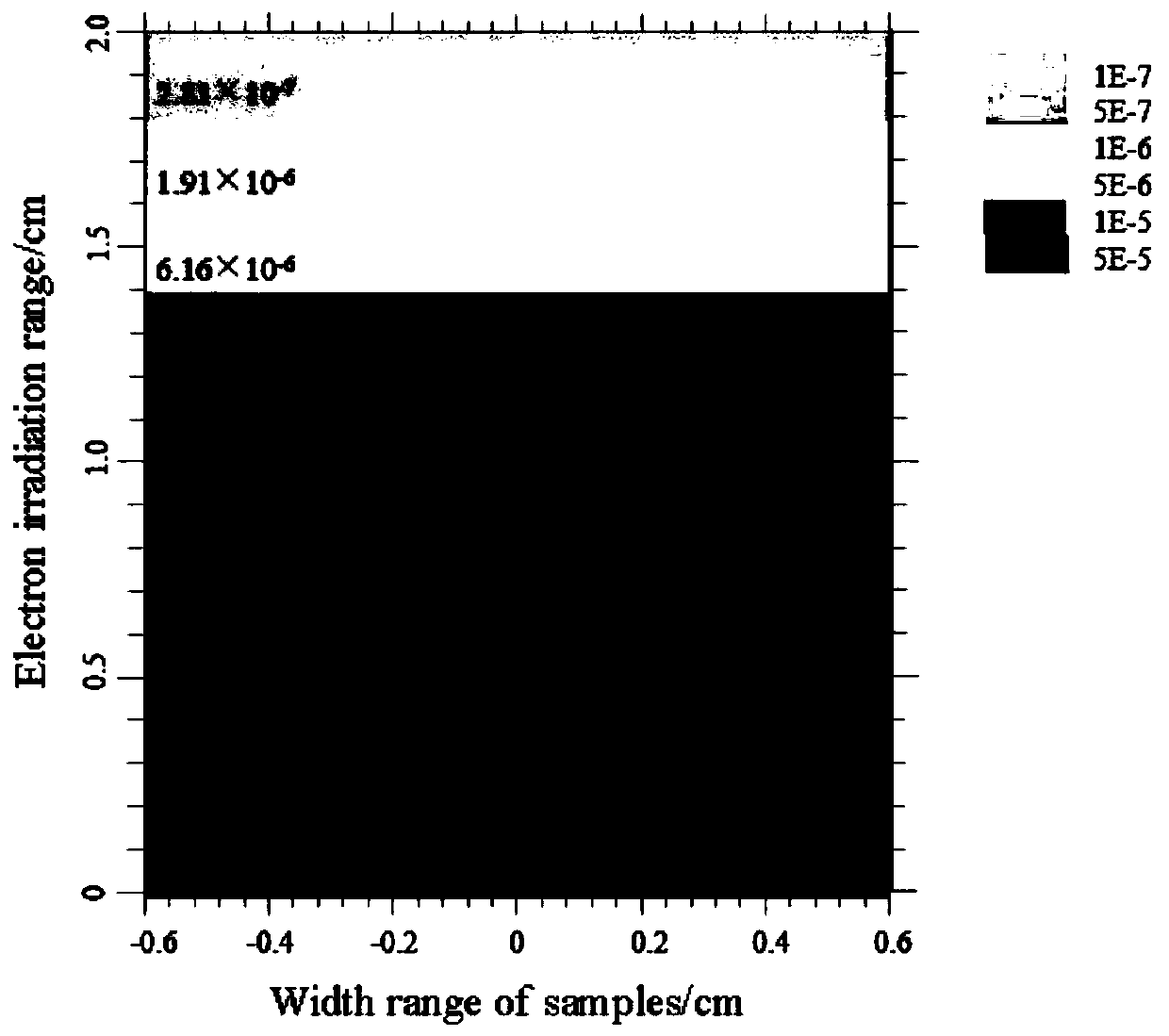

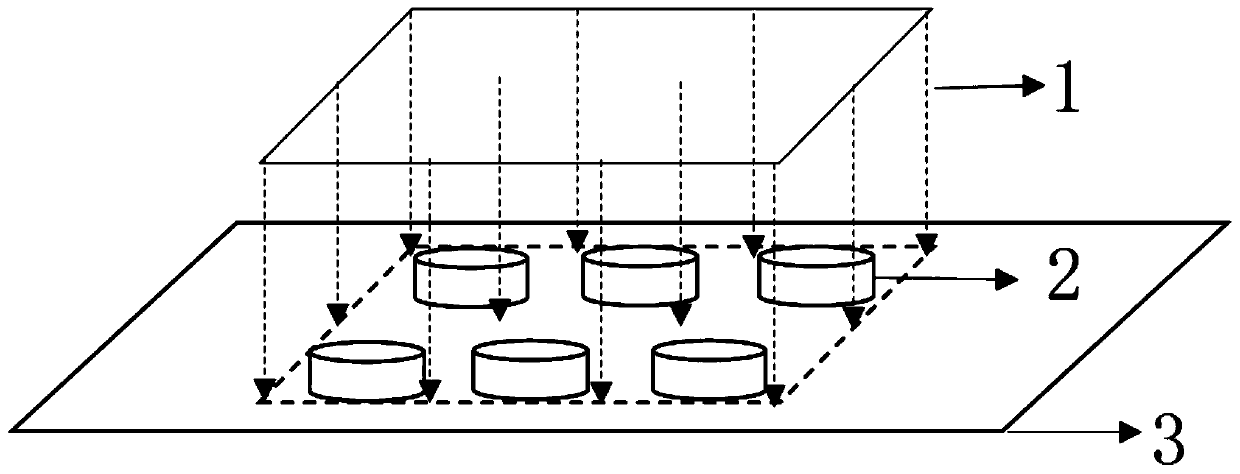

[0043] b. Transfer the HA block sample to a copper irradiated sample box with a height of 2 mm, place it evenly on the sample stage, and fix it with copper glue. The HA block sample is located directly below the irradiation window, and the electron beam will shoot vertically into the surface of the HA block sample. Turn on the electron accelerator, prepare for irradiation, control the energy of the electron accelerator at 1.19-1.21 M...

Embodiment 2

[0046] In this embodiment, the method for improving the degradability of apatite by electron irradiation comprises the following steps:

[0047] a. Put the HA powder into a φ13 tableting mold, use a hydraulic tablet press to apply a pressure of 2t and keep the pressure for half a minute, and get a small disc with a diameter of 13mm and a height of 2mm after demoulding. Subsequently, the wafer was placed in a muffle furnace for heat treatment at 400 °C for 1 h to obtain a HA block sample.

[0048] b. Transfer the HA block sample to a copper irradiated sample box with a height of 2 mm, place it evenly on the sample stage, and fix it with copper glue. The HA block sample is located directly below the irradiation window, and the electron beam will shoot vertically into the surface of the HA block sample. Turn on the electron accelerator, prepare for irradiation, control the energy of the electron accelerator at 1.19-1.21 MeV, the intensity of the electron beam at 5.00-5.70 mA, th...

Embodiment 3

[0051] In this embodiment, the method for improving the degradability of apatite by electron irradiation comprises the following steps:

[0052] a. Put the HA powder into a φ13 tableting mold, use a hydraulic tablet press to apply a pressure of 2t and keep the pressure for half a minute, and get a small disc with a diameter of 13mm and a height of 2mm after demoulding. Subsequently, the wafer was placed in a muffle furnace for heat treatment at 400 °C for 1 h to obtain a HA block sample.

[0053] b. Transfer the HA block sample to a copper irradiated sample box with a height of 2 mm, place it evenly on the sample stage, and fix it with copper glue. The HA block sample is located directly below the irradiation window, and the electron beam will shoot vertically into the surface of the HA block sample. Turn on the electron accelerator, prepare for irradiation, control the energy of the electron accelerator at 1.19-1.21 MeV, the intensity of the electron beam at 5.00-5.70 mA, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com