A kind of porous PTT fiber hoy silk and preparation method thereof

A fiber and spinneret technology, applied in the field of PTT fiber, can solve the problems of poor mechanical properties, uneven dyeing of PTT fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

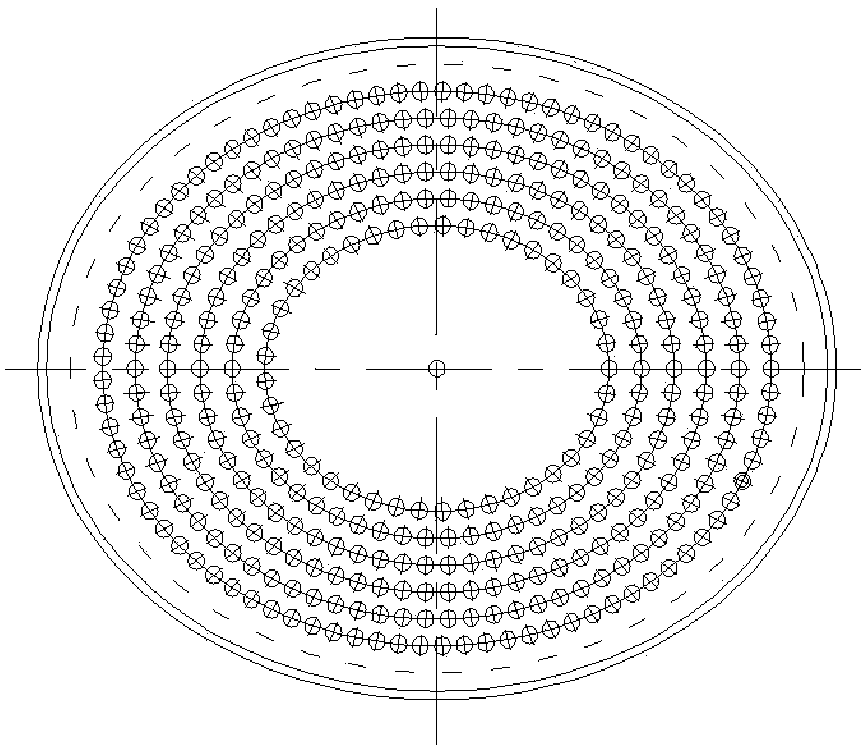

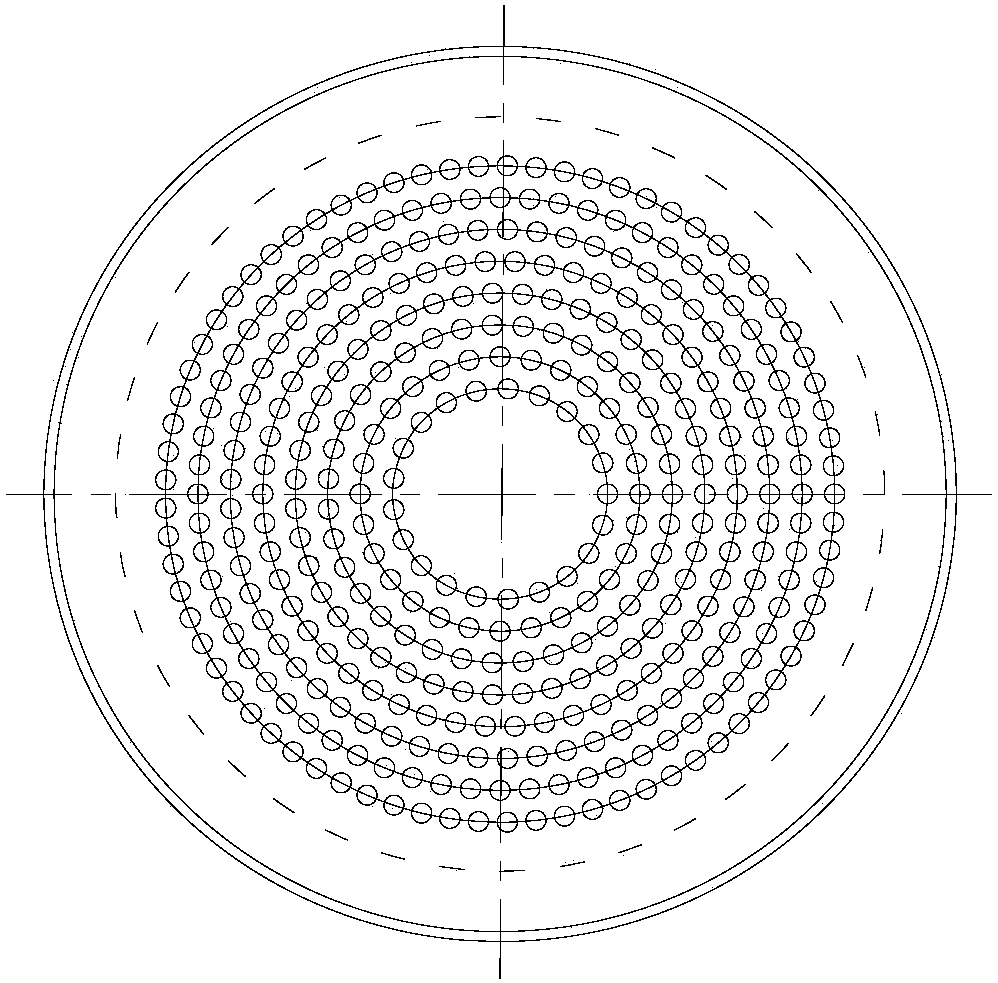

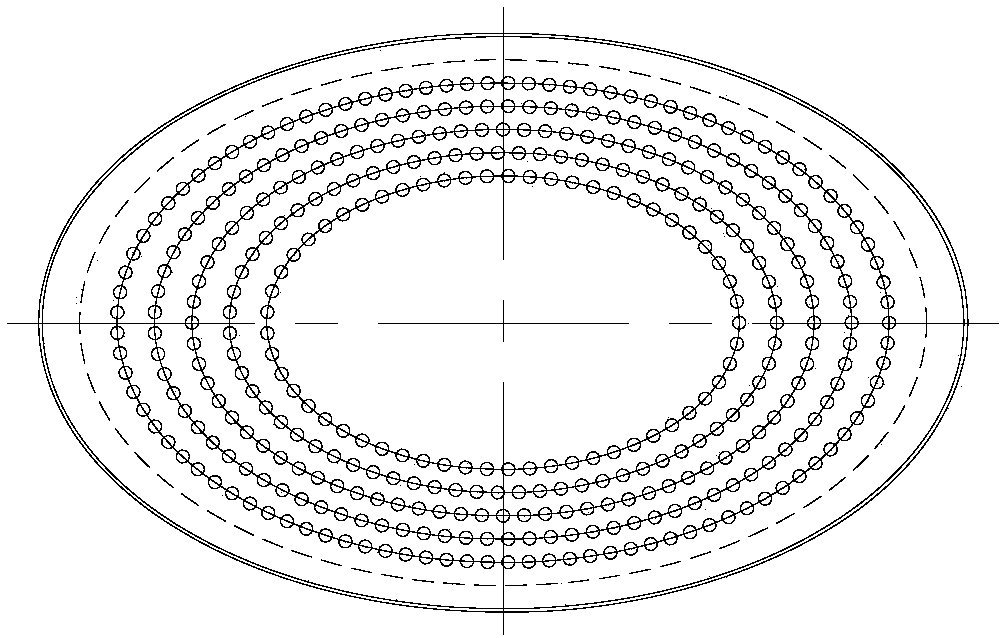

Image

Examples

Embodiment 1

[0062] A preparation method of modified PTT polyester, specifically comprising the following steps:

[0063] (1) Preparation of glycol terephthalate:

[0064] Put terephthalic acid and 2-pentyl-1,3 propanediol with a molar ratio of 1:1.3 into a slurry and add it to the reactor at a concentration of 50 wt%, and the addition amount is 0.3% of the weight of terephthalic acid. Under the catalysis of sulfuric acid, esterification reaction is carried out. The esterification reaction is pressurized in a nitrogen atmosphere. The pressurized pressure is normal pressure and the temperature is 180°C. Time is the end point of the esterification reaction to obtain diol terephthalate;

[0065] (2) Preparation of 1,3-propylene glycol terephthalate:

[0066] After making terephthalic acid and 1,3-propanediol into a slurry, carry out esterification reaction. The esterification reaction is pressurized in a nitrogen atmosphere, the pressure is controlled at normal pressure, and the temperature...

Embodiment 2

[0071] A preparation method of modified PTT polyester, specifically comprising the following steps:

[0072] (1) Preparation of glycol terephthalate:

[0073]Put terephthalic acid and 2-hexyl-1,3 propanediol with a molar ratio of 1:1.38 into a slurry and add to the reactor, at a concentration of 55wt%, add concentrated sulfuric acid in an amount of 0.32% of the weight of terephthalic acid Under the catalysis of the catalyst, the esterification reaction is carried out. The esterification reaction is pressurized in a nitrogen atmosphere. The pressurized pressure is 0.13 MPa and the temperature is 181 °C. For the end point of the esterification reaction, obtain diol terephthalate;

[0074] (2) Preparation of 1,3-propylene glycol terephthalate:

[0075] After making terephthalic acid and 1,3-propanediol into a slurry, carry out esterification reaction. The esterification reaction is pressurized in a nitrogen atmosphere, the pressure is controlled at normal pressure, and the temp...

Embodiment 3

[0080] A preparation method of modified PTT polyester, specifically comprising the following steps:

[0081] (1) Preparation of glycol terephthalate:

[0082] Put terephthalic acid with a molar ratio of 1:1.33 and 2-heptyl-1,3 propanediol into a slurry and add it to the reactor. Under the catalysis of sulfuric acid, esterification reaction is carried out. The esterification reaction is pressurized in a nitrogen atmosphere. The pressurized pressure is 0.12 MPa and the temperature is 183 ° C. When the amount of water distilled in the esterification reaction reaches 92% of the theoretical value Time is the end point of the esterification reaction to obtain diol terephthalate;

[0083] (2) Preparation of 1,3-propylene glycol terephthalate:

[0084] After making terephthalic acid and 1,3-propanediol into a slurry, carry out esterification reaction. The esterification reaction is pressurized in a nitrogen atmosphere, the pressure is controlled at normal pressure, and the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com