Calibration platform of FBG sensor

A technology for calibrating platforms and fiber gratings, which is applied to instruments, optical devices, measuring devices, etc., can solve the problems of small ductility of fiber grating sensors, and it is not easy to stretch fiber grating sensors, and achieves easy operation, convenient measurement and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

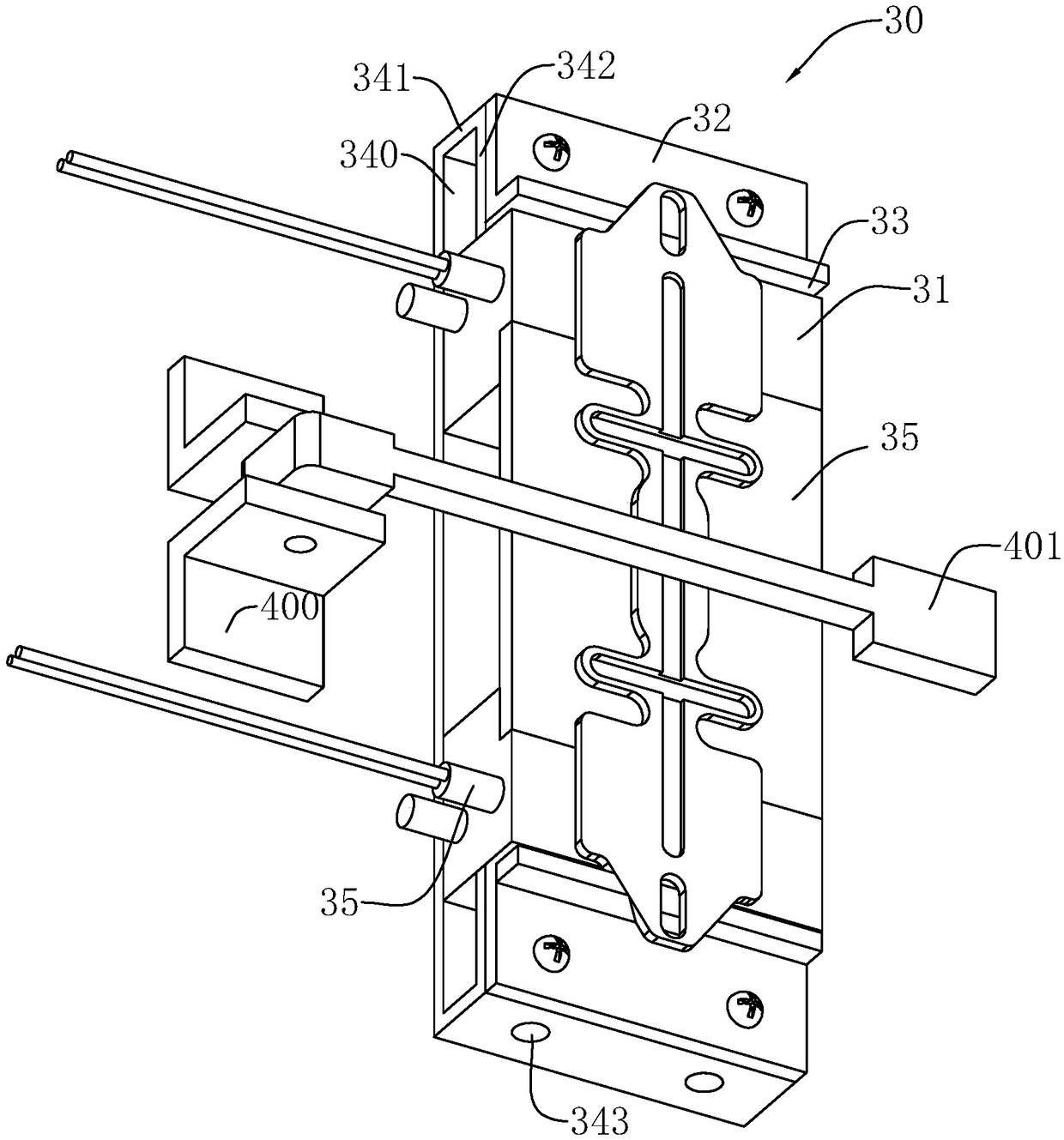

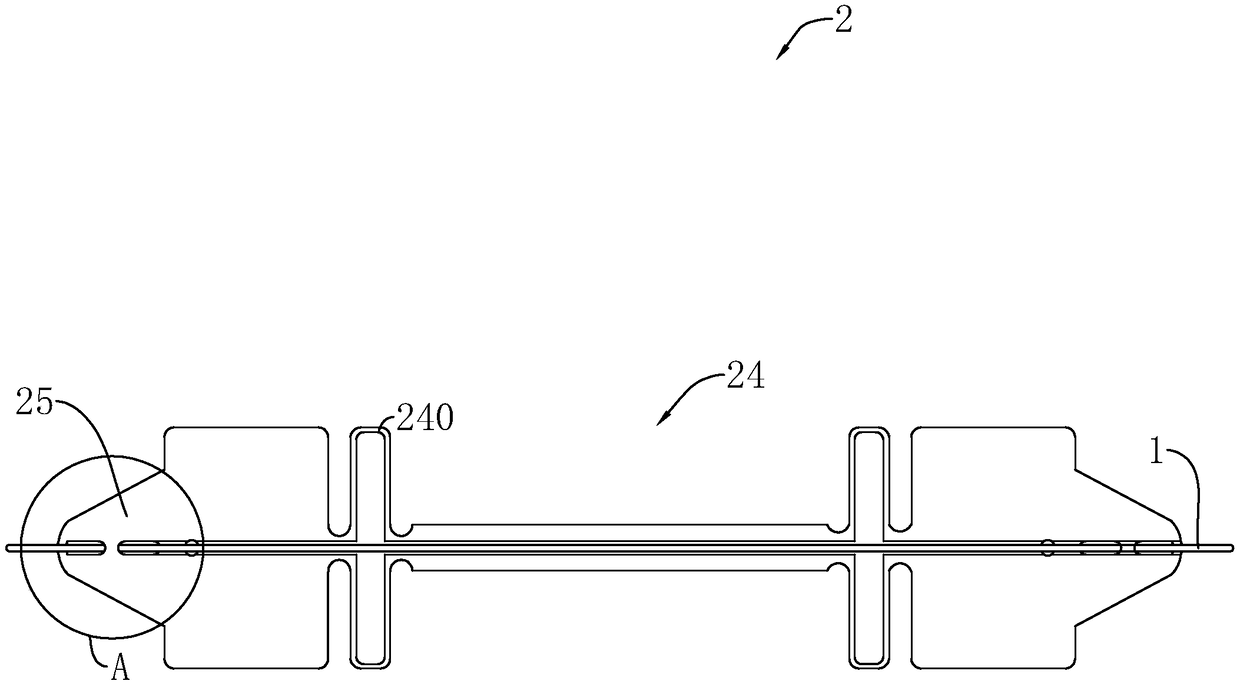

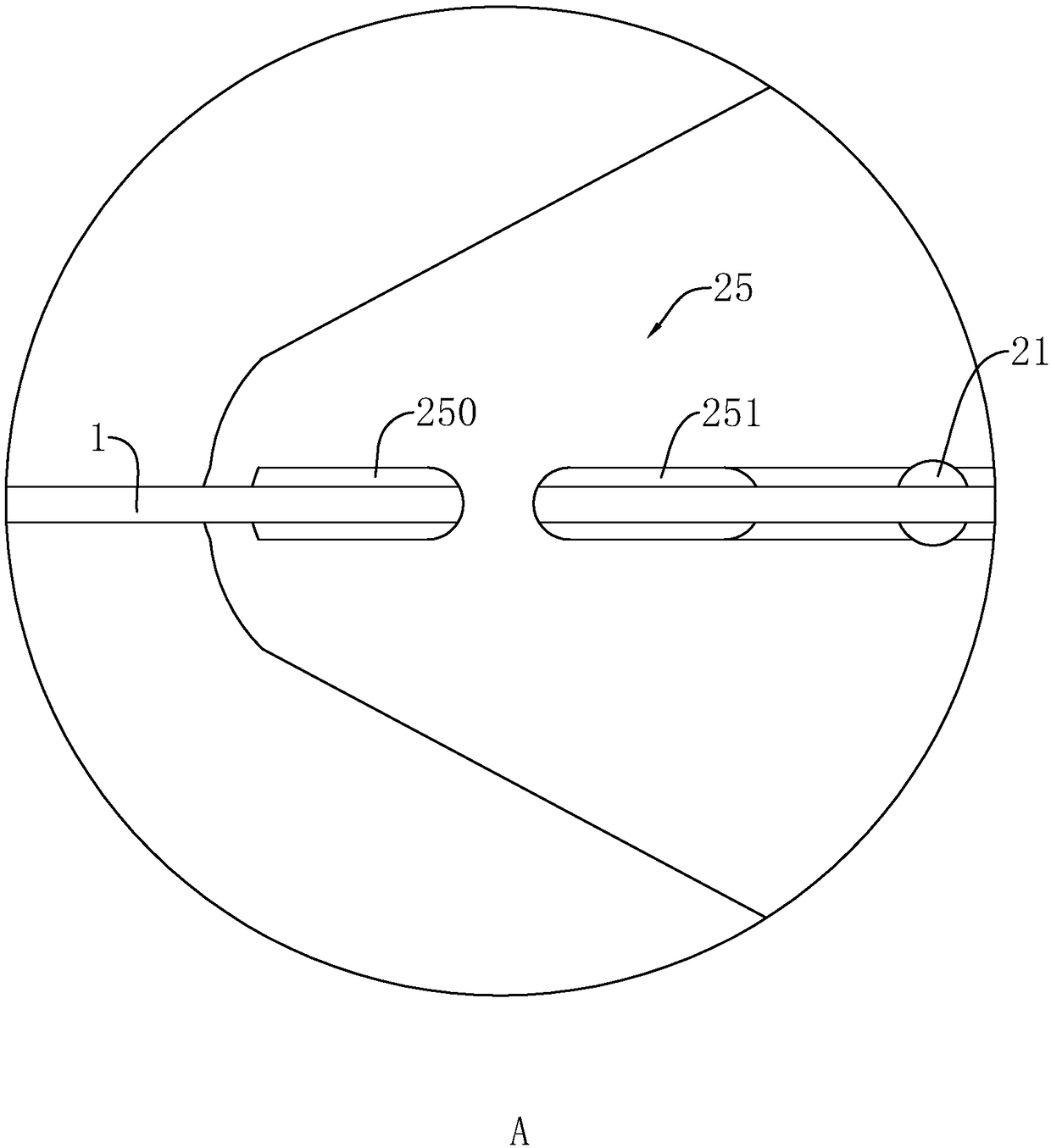

[0043] Embodiment 1, a kind of fiber grating sensor, with reference to figure 1 , figure 2 , including a frame for encapsulating the optical fiber 1 and the optical fiber 1 passing through the frame sheet 2, the frame can be set in a cylindrical shape, a flat shape or a cube shape, preferably a flat frame sheet 2 in this embodiment, a flat shape The frame piece 2 can be easily fixed or installed with the equipment under test. The optical fiber 1 inside the frame piece 2 is engraved with a grating. When the grating is deformed, the spectrum passing through the grating will be changed. After the optical fiber 1 enters the frame piece 2, a Reflection, forming reflection spectrum and refraction spectrum. By observing the changes of the two spectra, the deformation of the grating can be reflected. The grating is packaged on the frame sheet 2, and the frame sheet 2 is pasted on the device to be measured, and the slight deformation of the device can be felt. After the corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com