Lithium ion battery state-of-charge estimation method based on embedded optical fiber sensor

A lithium-ion battery and optical fiber sensor technology, applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., can solve problems such as direct information, inability to provide battery physical and chemical states, limited measurability, etc., and achieve the effect of improving estimation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

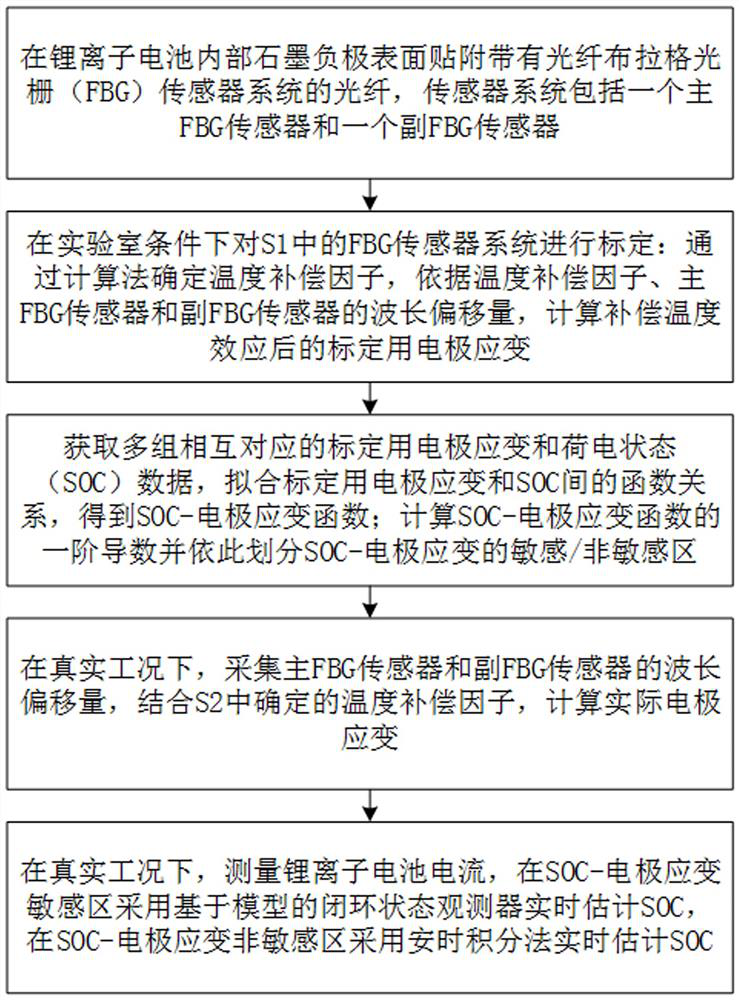

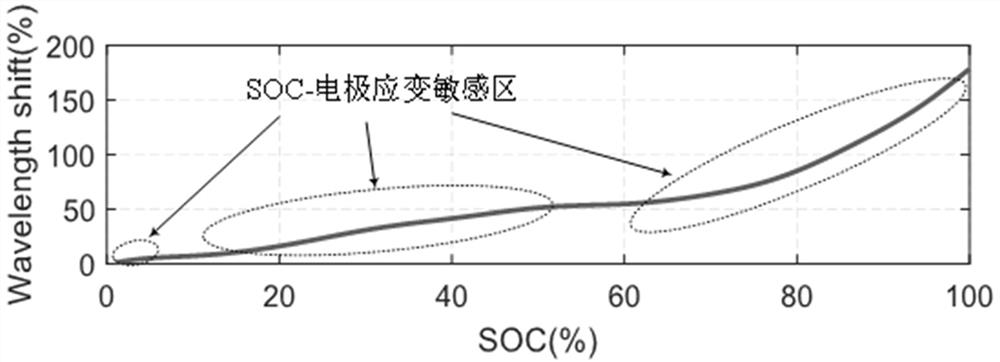

[0020] like figure 1 As shown, a lithium-ion battery state-of-charge estimation method based on an embedded fiber optic sensor includes the following steps:

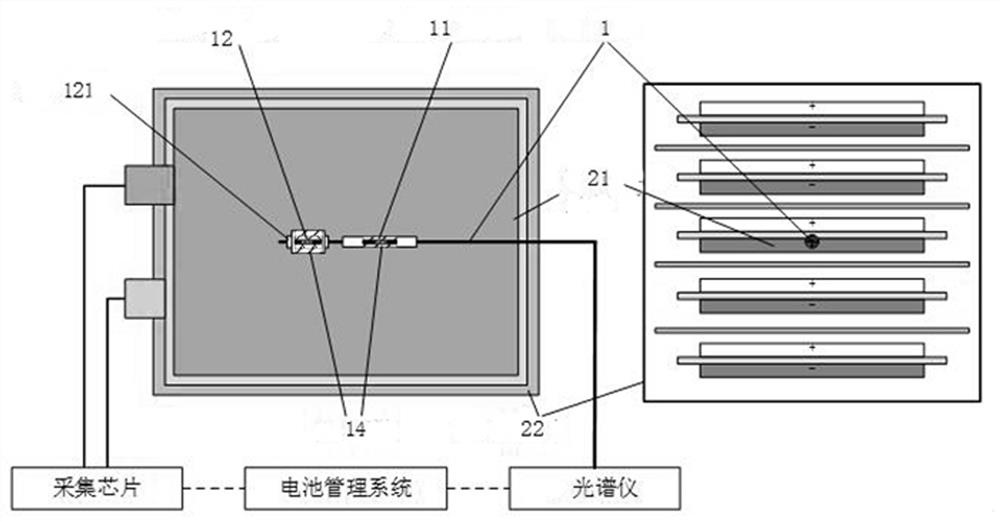

[0021] S1. An optical fiber 1 with a FBG sensor system is attached to the surface of the graphite negative electrode 21 inside the lithium-ion battery. The FBG sensor system includes a main FBG sensor 11 and a secondary FBG sensor 12, such as figure 2 Shown, where the FBG sensor system refers to the fiber Bragg grating sensor system.

[0022] S101. Photoetching two Bragg grating microstructures in series in one core of the same optical fiber. The section inscribed with a Bragg grating microstructure in the core of the optical fiber 1 is used as the main FBG sensor 11 . The wavelen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com