Novel FBG temperature sensor based on low-melting glass, and packaging process of the same

A low-melting glass and temperature sensor technology, applied to thermometers, thermometers, instruments, etc. that change physically/chemically, can solve problems such as high cost, complicated process, and reduced sensing accuracy, and achieve high reliability and simple packaging process , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

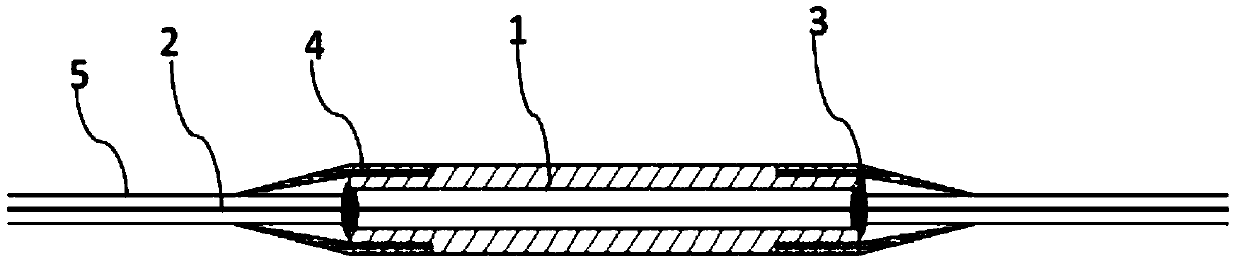

[0022] Such as figure 1 , is the novel FBG temperature sensor packaging structure based on low-melting glass of the present invention. The package structure includes alumina ceramic tube 1 , polyimide FBG 2 , low-melting glass 3 , rubber boot 4 and high temperature protection cover 5 . Among them, the polyimide FBG 2 passes through the alumina ceramic tube 1, and is in the center of the alumina ceramic tube 1, and the two are parallel to each other; the alumina ceramic tube 1 is connected to the polyimide ceramic tube 1 from both ends by using the low melting point glass 3. The imine FBG 2 forms a submerged state to form a ceramic tube-FBG combination; the rubber boot 4 is respectively sleeved on both ends of the alumina ceramic tube 1 by means of interference fit; the high-temperature protection s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com