Method and system for measuring concentration of chemical solution by fiber bragg gratings (FBG)

A fiber grating and chemical solution technology, applied in color/spectral characteristic measurement, measurement devices, material analysis through optical means, etc., can solve problems such as high risk and impossibility, and achieve high safety and accurate measurement results , the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

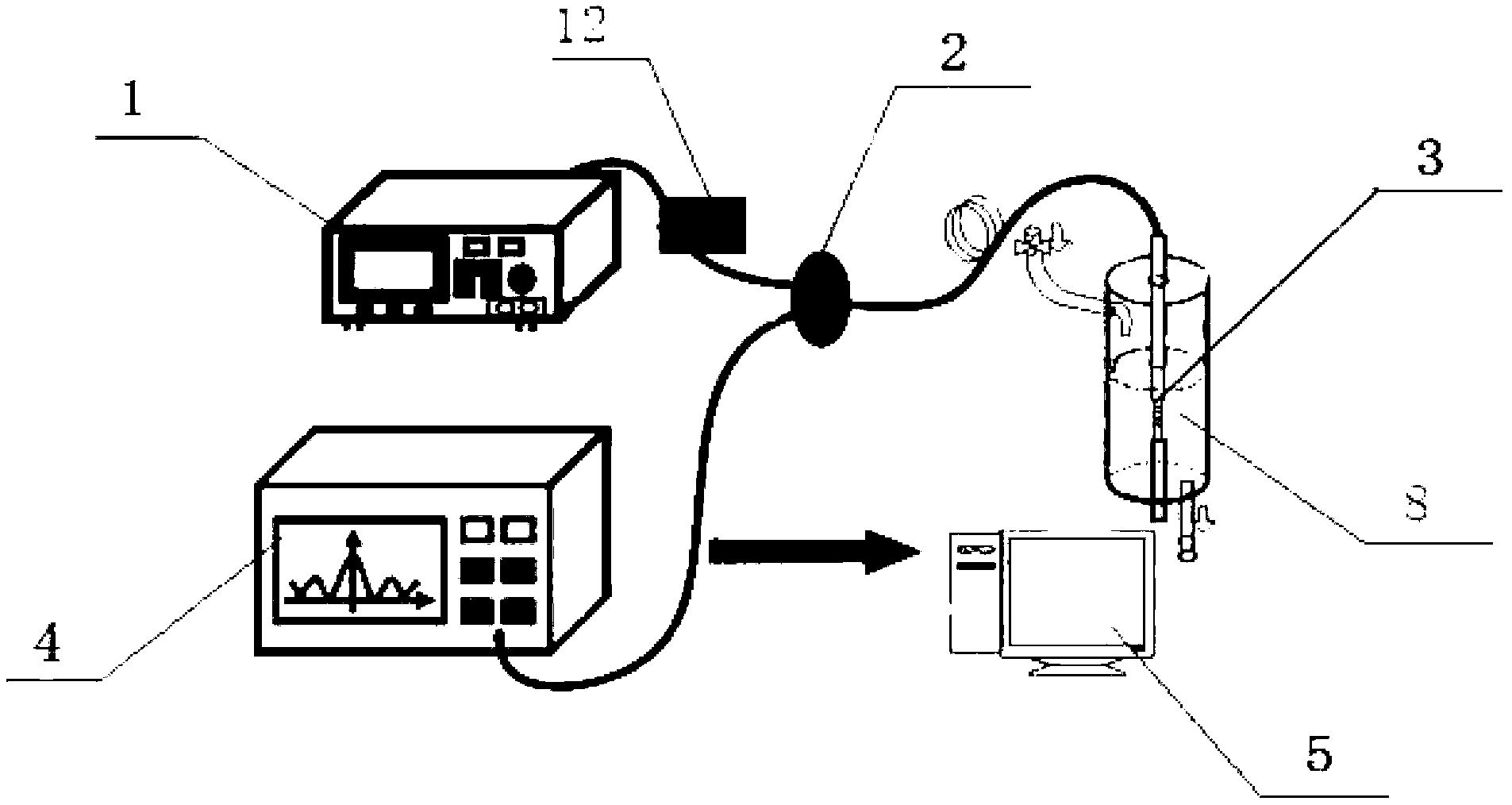

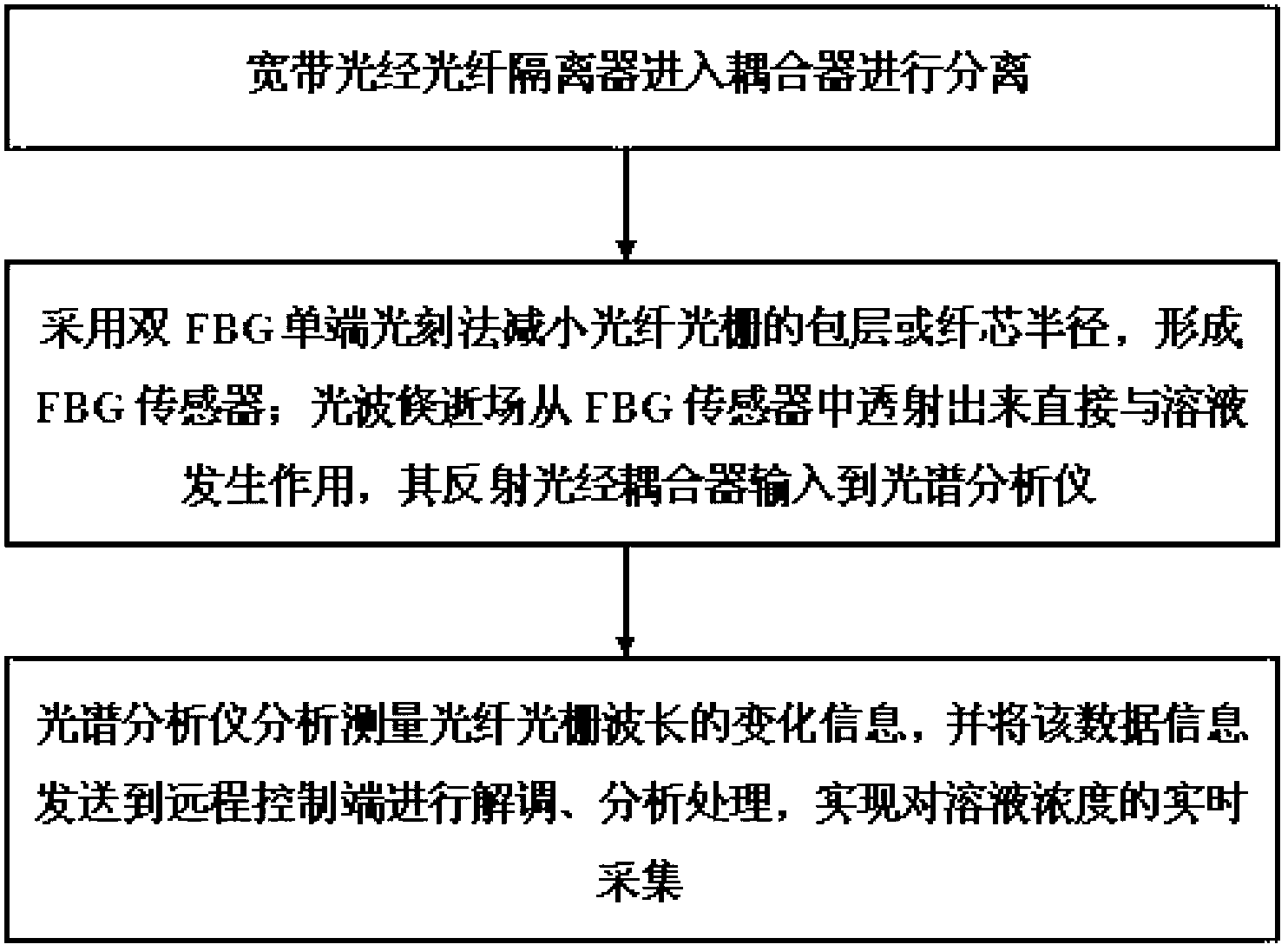

[0034] Embodiment 1 of the present invention: a kind of method utilizing optical fiber grating to measure chemical solution concentration, comprises the following steps:

[0035] S1, the broadband light enters the coupler through the fiber isolator for separation;

[0036] S2, using double FBG single-ended photolithography to reduce the cladding or core radius of the fiber grating to form a FBG sensor; the evanescent field of light wave is transmitted from the FBG sensor to directly interact with the solution, and the reflected light is input to the spectrum analyzer;

[0037] S3, the spectrum analyzer analyzes and measures the change information of the fiber grating wavelength, and sends the data information to the remote control terminal for demodulation, analysis and processing, so as to realize the real-time collection of the solution concentration.

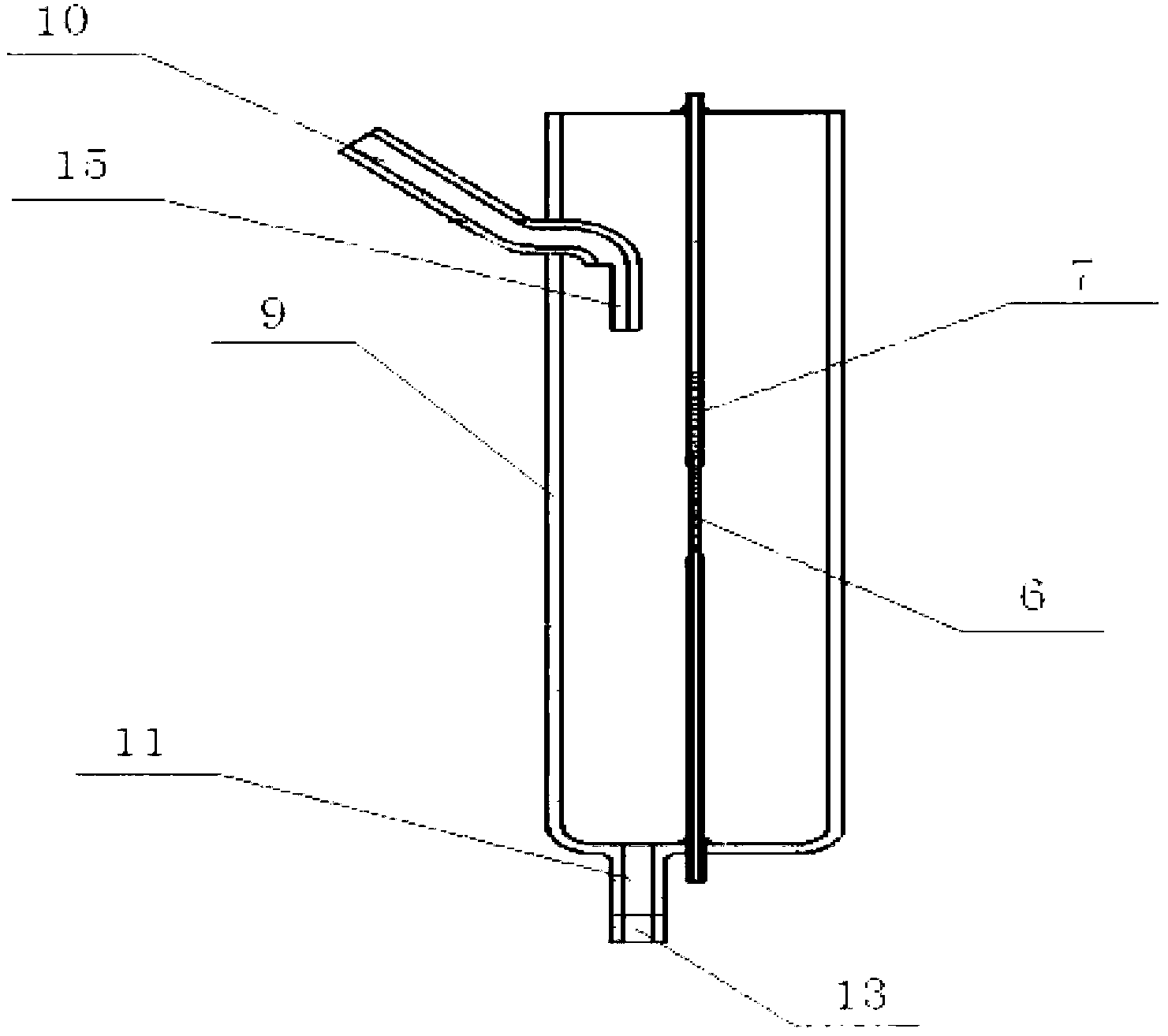

[0038] In step S2, the double-FBG single-ended lithography method refers to first placing the sensitive grating on a preci...

Embodiment 2

[0055] Embodiment 2: a kind of method utilizing optical fiber grating to measure chemical solution concentration, comprises the following steps:

[0056] S1, the broadband light enters the coupler through the fiber isolator for separation;

[0057] S2, using double FBG single-ended photolithography to reduce the cladding or core radius of the fiber grating to form a FBG sensor; the evanescent field of light wave is transmitted from the FBG sensor to directly interact with the solution, and the reflected light is input to the spectrum analyzer;

[0058] S3, the spectrum analyzer analyzes and measures the change information of the fiber grating wavelength, and sends the data information to the remote control terminal for demodulation, analysis and processing, so as to realize the real-time collection of the solution concentration.

[0059]A system for measuring the concentration of a chemical solution using an optical fiber grating to achieve the above method, comprising: a bro...

Embodiment 3

[0060] Embodiment 3: a kind of method utilizing optical fiber grating to measure chemical solution concentration, comprises the following steps:

[0061] S1, the broadband light enters the coupler through the fiber isolator for separation;

[0062] S2, using double FBG single-ended photolithography to reduce the cladding or core radius of the fiber grating to form a FBG sensor; the evanescent field of light wave is transmitted from the FBG sensor to directly interact with the solution, and the reflected light is input to the spectrum analyzer;

[0063] S3, the spectrum analyzer analyzes and measures the change information of the fiber grating wavelength, and sends the data information to the remote control terminal for demodulation, analysis and processing, so as to realize the real-time collection of the solution concentration.

[0064] A system for measuring the concentration of a chemical solution using an optical fiber grating to realize the above method, comprising: a br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com