Rigid body mode testing method for powertrain mounting system under loading condition

A powertrain and testing method technology, which is applied in vehicle testing, machine/structural component testing, vehicle suspension/shock absorbing mechanism testing, etc., can solve the problems of lack of effective testing methods, powertrain damage, and vibration exciter operation. Space limitations and other issues, to achieve the effect of saving test costs, practical test methods, and test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

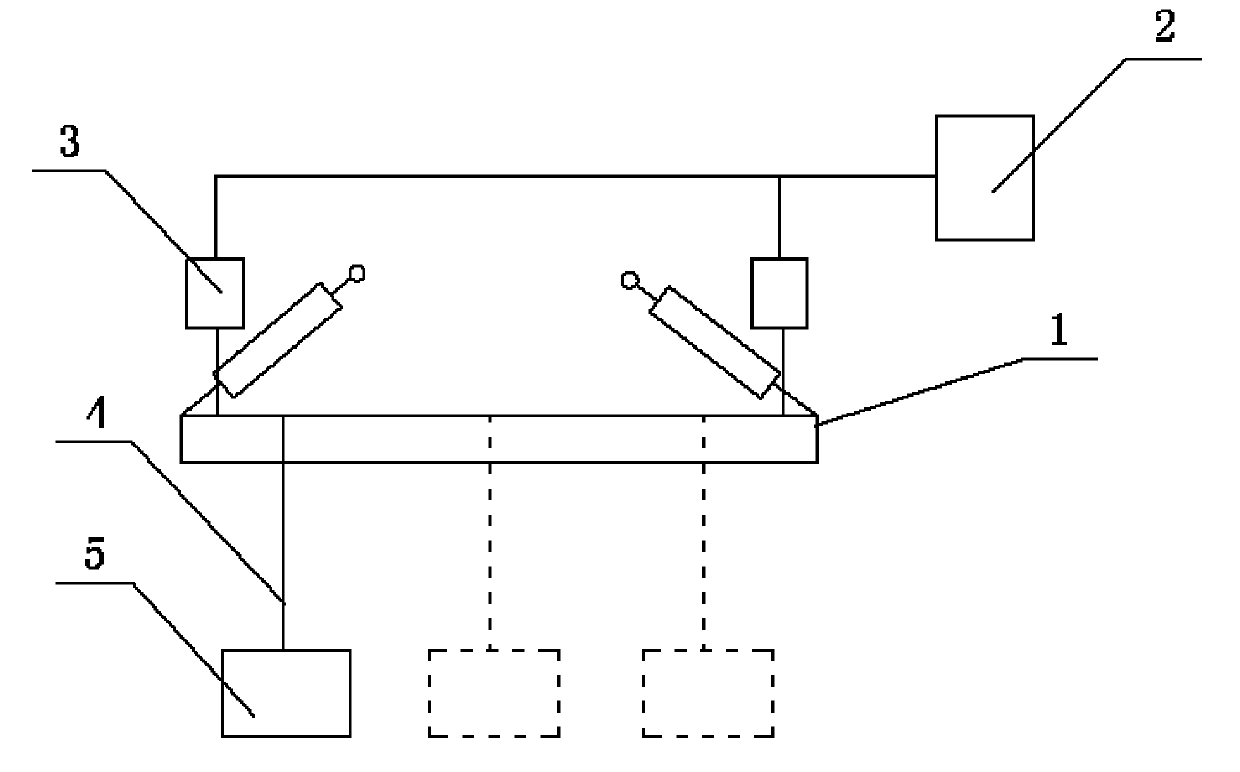

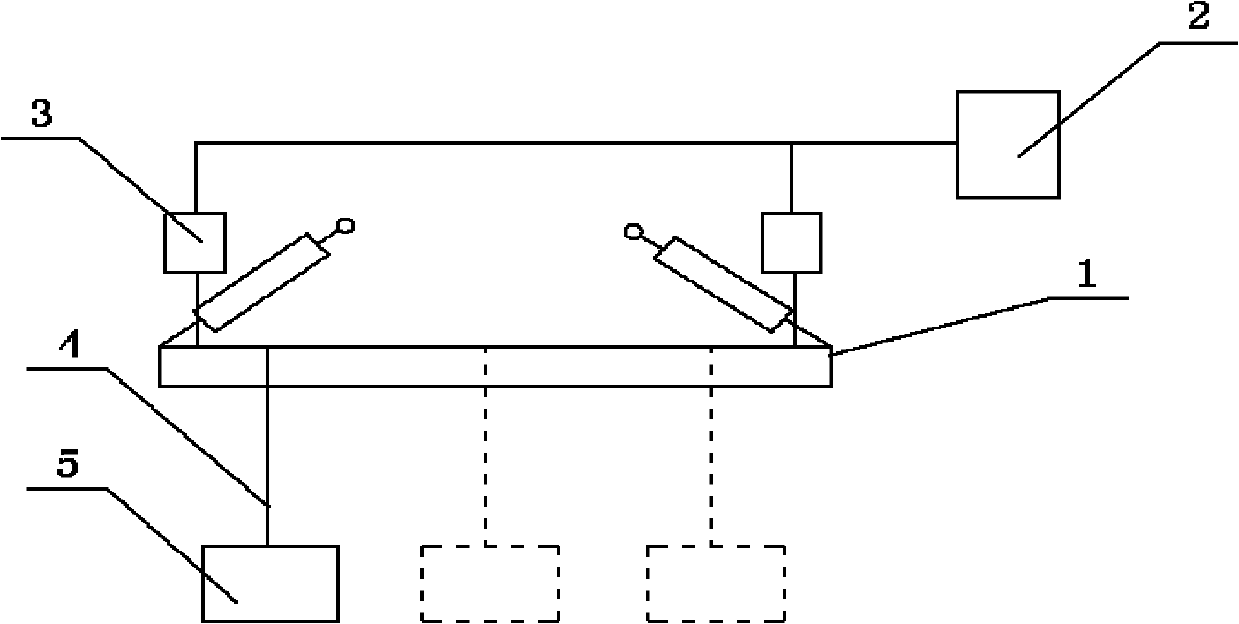

[0025] Embodiment 1: as figure 1 As shown, a rigid body modal test method of the powertrain suspension system under the loading condition, the equipment part includes a powertrain suspension device 1 for testing, a vibration sensor 3 and a data acquisition device 2, and also includes A weight 5 and a rope 4 are used for auxiliary testing. The mass of the weight 5 is two-fifths of the total weight of the powertrain suspension device 1 of the vehicle to be tested. Two vibration sensors 3 are arranged on the powertrain suspension device 1 , and the above vibration sensors 3 are connected to the data acquisition device 2 .

[0026] Before the preparation of the rigid body mode test method, the whole vehicle is lifted to a certain height through the lift, and then the following test method steps are implemented:

[0027] Step S1: hanging the heavy object 5 on one side of the powertrain suspension device 1 through the rope 4;

[0028] Step S2: Re-initialize the modal test and anal...

Embodiment 2

[0032] Embodiment 2: Before the preparation of the rigid body mode test method, the four wheels of the whole vehicle are emptied and placed on the maintenance platform with a ditch in the middle. All the other are with embodiment 1.

Embodiment 3

[0033] Embodiment 3: In steps S1 and S4, the force surface between the rope 4 and the powertrain suspension device 1 is increased by adding a sheath on the rope 4, so as to avoid excessive local force and prevent powertrain causes Damage caused by excessive local force. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com