Method for detecting blow-by of hydrogen and oxygen in fuel cell stack quickly

A fuel cell stack and detection method technology, which is applied in the direction of fuel cell grouping, current/voltage measurement, and electricity measurement, can solve problems such as difficult to determine the specific position of hydrogen-oxygen cross-gas in the stack, and achieve the promotion of commercial development, Solve safety hazards and test accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The specific embodiment is to carry out the detection of hydrogen-oxygen gas crossover to a newly assembled 128-cell fuel cell stack, and its specific working steps are as follows:

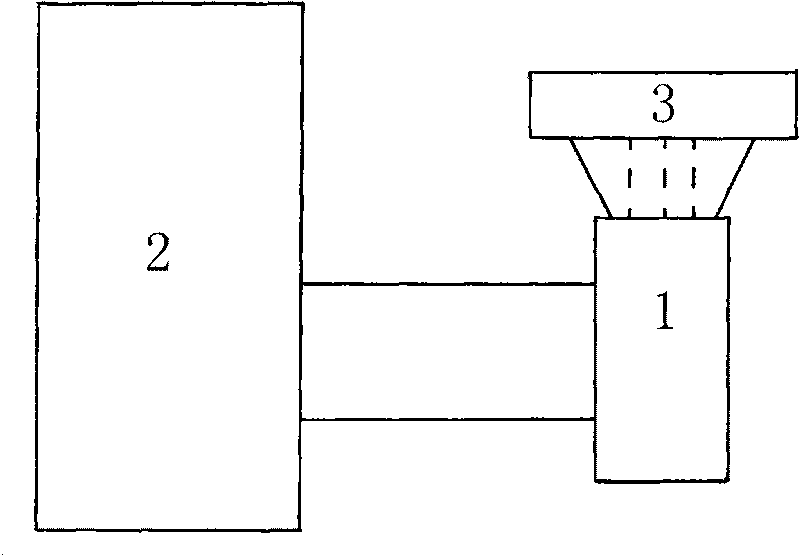

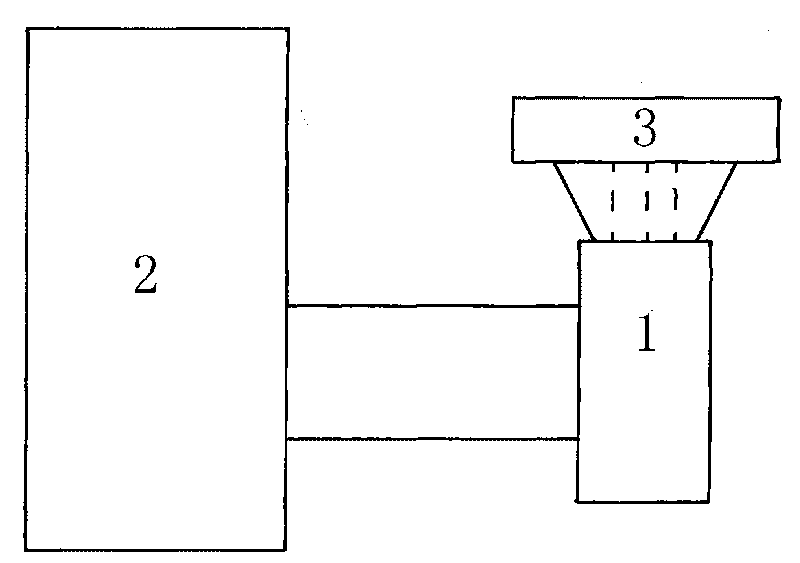

[0016] a. Install the 128-cell fuel cell stack on the fuel cell testing platform, connect the gas pipeline between the stack and the test platform, and connect the fuel cell stack and the voltage detection line of the stack voltage inspection system;

[0017] b. Introduce 30kpa of detection gas with a hydrogen volume concentration of 20% into the anode chamber of the electric stack, the detection gas is a mixed gas of hydrogen and nitrogen, and feed 20kpa of air into the cathode chamber of the electric stack as the detection gas;

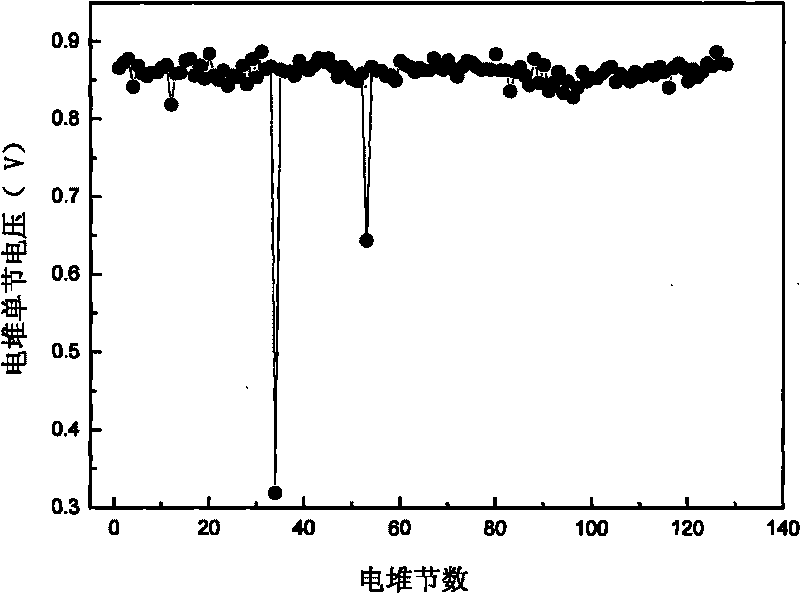

[0018] c. When the voltage of each node in the stack reaches an open circuit state of 0.9V or more, stop the introduction of the detection gas on the cathode side, and then hold down the pressure of the detection gas on the anode side to 50kpa for 1 minute, observ...

Embodiment 2

[0021] Change the detection gas that feeds into the cathode cavity of the electric stack in embodiment 1 into a mixed gas of oxygen and nitrogen; wherein, the volume concentration of oxygen is 10%, and the pressure is 20kpa, and other steps are the same as in embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com