Bushing non-uniform external pressure loading test device and bushing non-uniform external pressure loading test method

A loading test device and non-uniform external pressure technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of not considering non-uniform external pressure, aggravating the non-uniform effect of casing external pressure, etc., and achieve the test The method is simple and easy, the effect of increasing the test cost and low test cost

Active Publication Date: 2013-09-18

BC P INC CHINA NAT PETROLEUM CORP +1

View PDF6 Cites 27 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Especially for the developing process of coalbed methane and shale gas, factors such as changes in ground stress due to long-distance horizontal well sections and repeated acidizing and fracturing processes have exacerbated the non-uniformity of casing external pressure effect

At present, most of the traditional casing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Inner diameter range | aaaaa | aaaaa |

Login to View More

Abstract

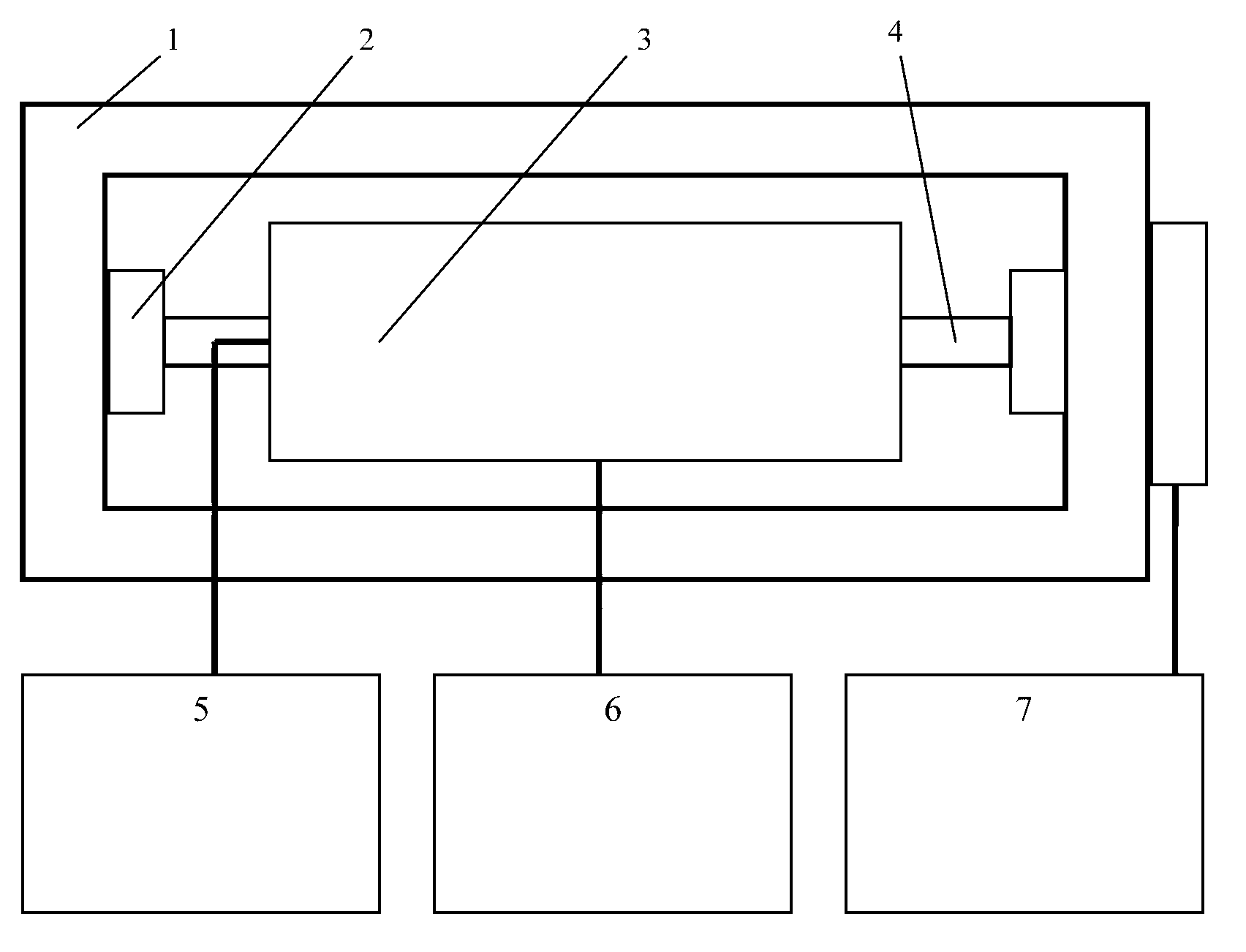

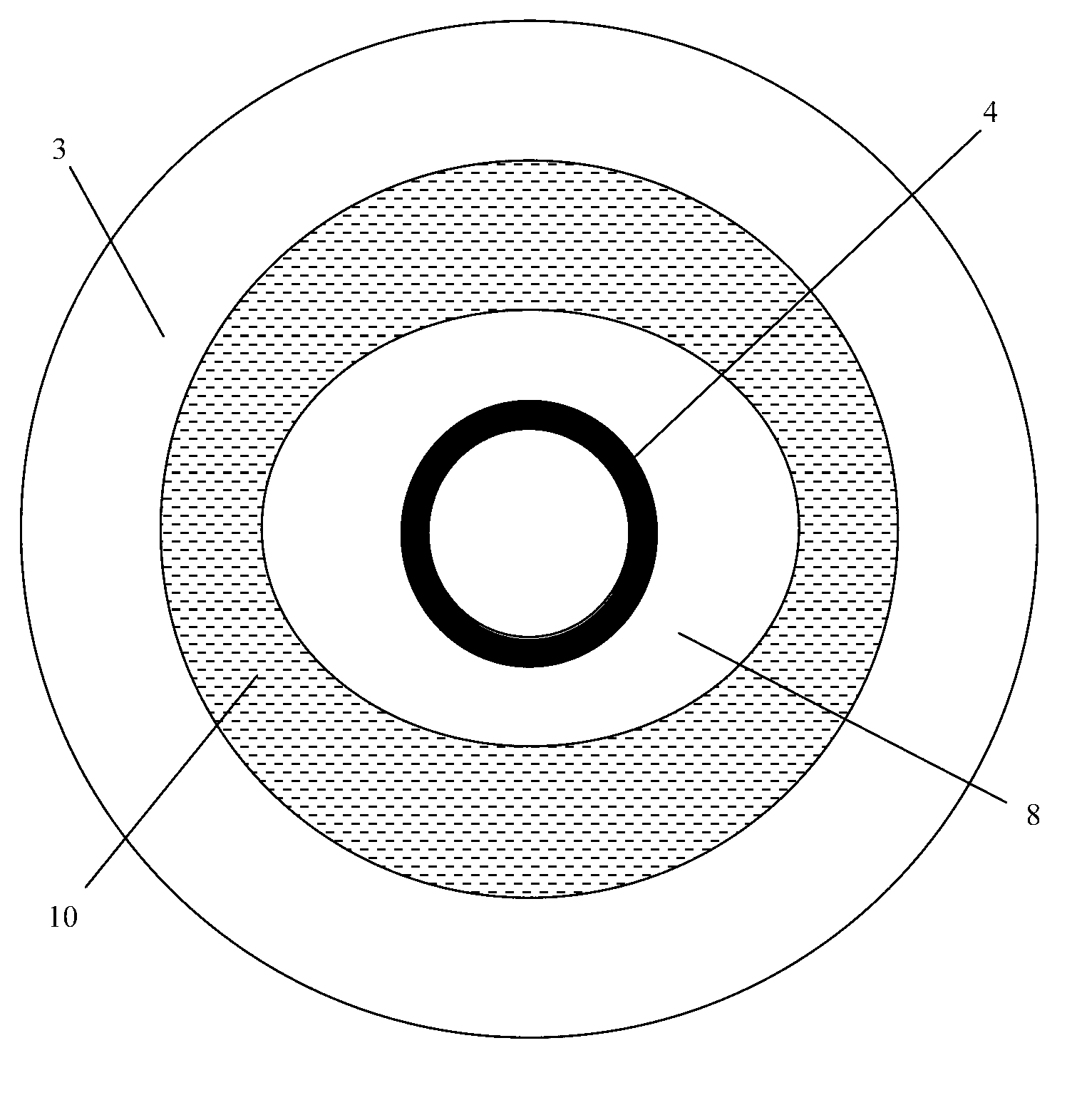

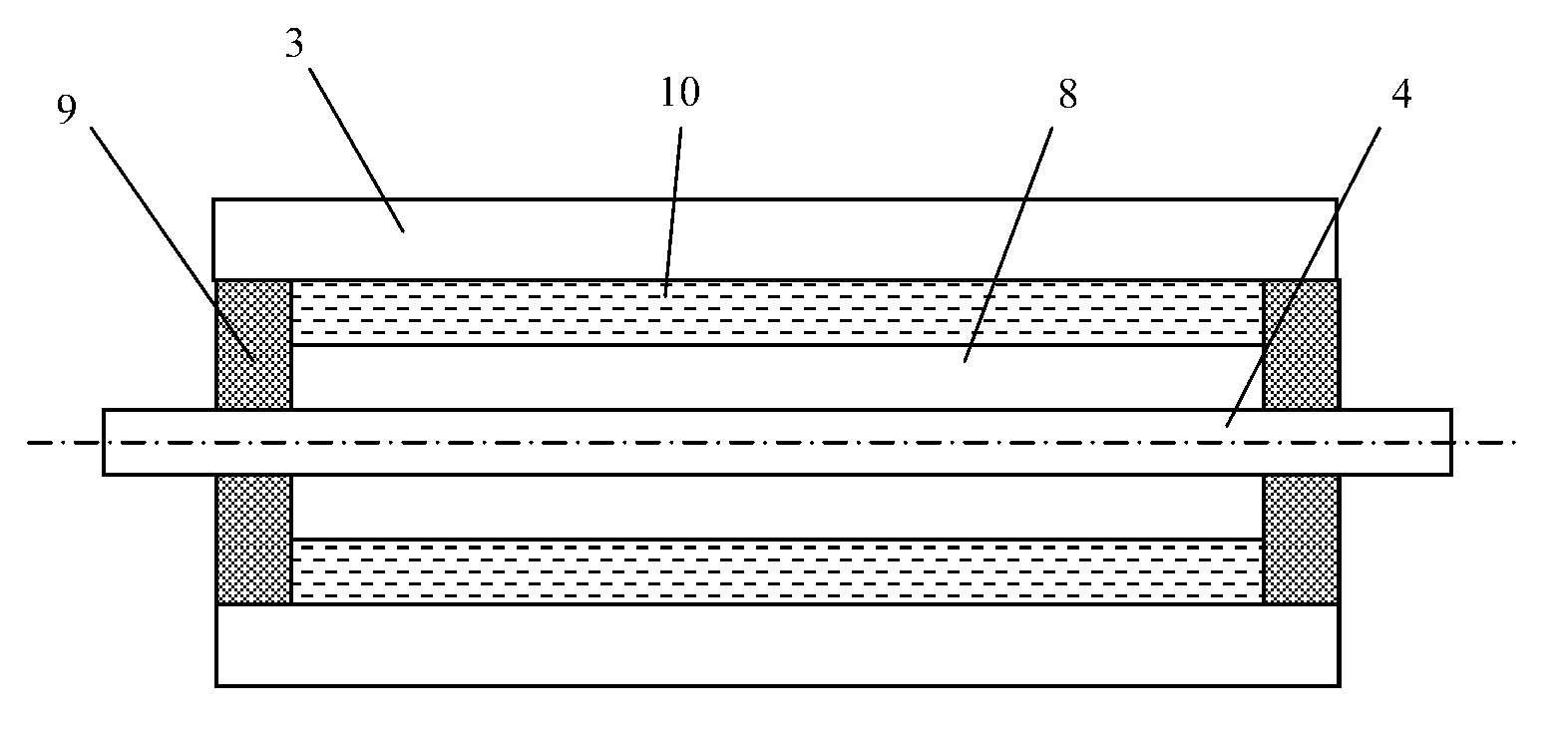

The invention discloses a bushing non-uniform external pressure loading test device and a bushing non-uniform external pressure loading test method. The bushing non-uniform external pressure loading test device comprises, a rubber sleeve, an extruding cylinder, a mechanical plugging device, an external pressure loading system, an end clamping mechanism and a pressure detecting system, wherein the rubber sleeve is tubular rubber, a channel with the circular section is arranged at the axial centre, the rubber sleeve is sleeved outside a to-be-tested bushing, the periphery of the cross section of the rubber sleeve is a non-circular curved surface, an extruding cylinder is sleeved outside the rubber sleeve to form a pressure cavity for containing a high-pressure medium; the mechanical plugging device is hermetically arranged at two ends of the extruding cylinder, the centre of the mechanical plugging device is provided with a bushing hole through which a bushing is capable of passing; two ends of the rubber sleeve prop against the inner sides of the mechanical plugging device, and the space between the bushing hole of the mechanical plugging deice and the peripheral wall of the bushing is sealed; the external pressure loading system is communicated with the extruding cylinder and used for injecting the high-pressure medium into the extruding cylinder; the end clamping mechanism is used for clamping two ends of the bushing; the pressure detecting system is used for detecting the pressure on the outer wall of the bushing through a pressure sensor arranged on the outer wall of the bushing; the end clamping mechanism is fixed on a test frame. The combined loading pressure test for applying non-uniform external pressure is realized according to the device disclosed by the invention.

Description

technical field [0001] The invention relates to a casing external pressure loading test, in particular to a casing non-uniform external pressure loading test device and method. Background technique [0002] The collapse of oil casing under external pressure during service is one of the main failure modes. Many practices and studies have shown that the collapse and failure of a large number of casings is caused by non-uniform formation external pressure loads. Under the action of non-uniform external pressure, stress concentration occurs inside the casing, which is more likely to cause deformation or instability of the casing and loss of bearing capacity than when it is subjected to uniform external pressure. During the development and production of oil and gas wells, due to the creep effect of rock-salt layers, mudstone layers, etc., as well as other complex geological factors and engineering factors, the casing confining pressure is unevenly distributed. Especially for the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/12

Inventor 王鹏胡美娟申昭熙宋生印李磊冯春

Owner BC P INC CHINA NAT PETROLEUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com