Method for testing and analyzing frictional noise and test device for method

A technology of friction noise and analysis methods, applied in the direction of measuring devices, analyzing materials, and adopting mechanical devices, etc., can solve the problems of high test repeatability and test accuracy, difficulty in manual control reproduction or simulation, etc., and achieve control and test accuracy High, high degree of automation, improve the effect of related design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

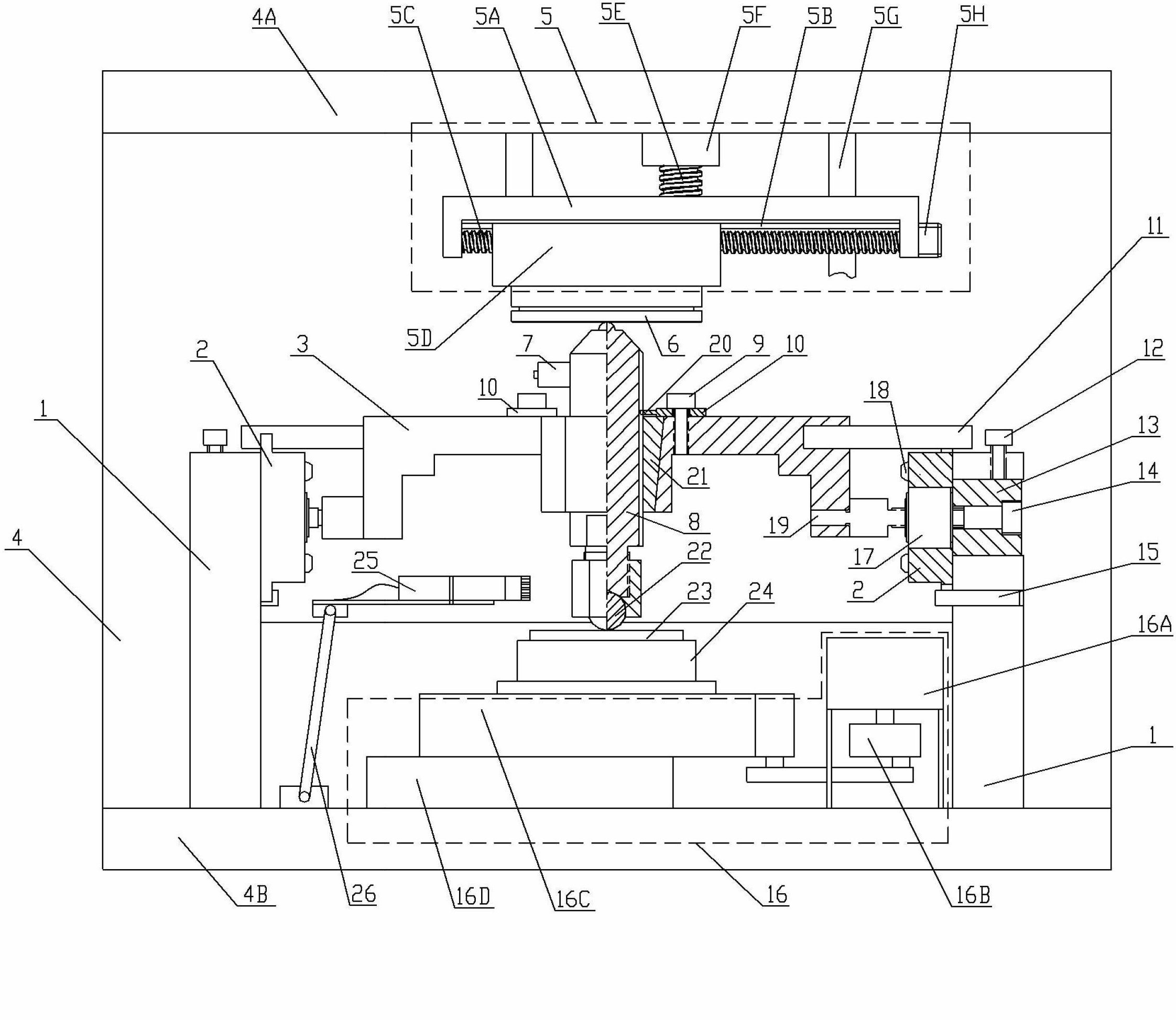

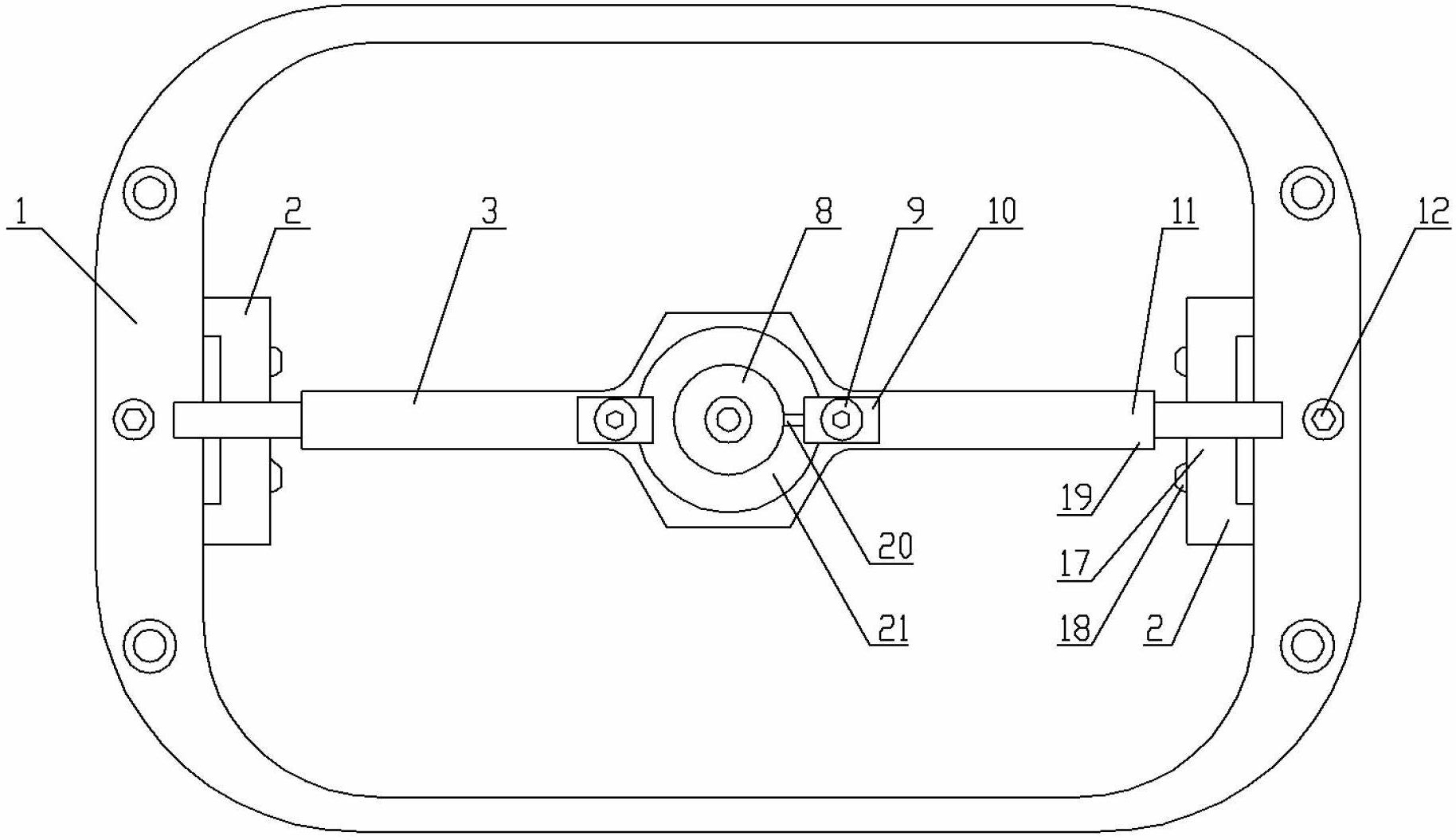

[0057] figure 1 , figure 2 Shown, an embodiment of the present invention is: a kind of test analysis method of frictional noise, and its practice is:

[0058] The lower friction part 23 of the friction pair is clamped on the lower fixture 24, and the lower fixture 24 is fixed on the reciprocating device 16; the upper friction part 22 of the friction pair is clamped by the upper fixture 8, and the upper fixture 8 passes through the horizontal bracket 3 and the strain The bottom surface of the force sensor 6 is in contact with the three-dimensional acceleration sensor 7 on the side of the upper fixture 8. The two ends of the horizontal support 3 are fixed on the support base 1 through the piezoelectric force sensor 17, and the strain force sensor 6 is fixed on the two-dimensional mobile The bottom of the table 5; the sensing end of the acoustic sensor 25 is located near the contact interface of the upper and lower friction members 22 and 23;

[0059] Control the up and down, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com