Optical parameter detection method of low-radiation coated glass

A low-radiation coating and detection method technology, applied in the field of energy-saving coated glass detection, can solve the problems of detection deviation, difficulty in obtaining fine structure optical parameters of composite films, discrepancies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

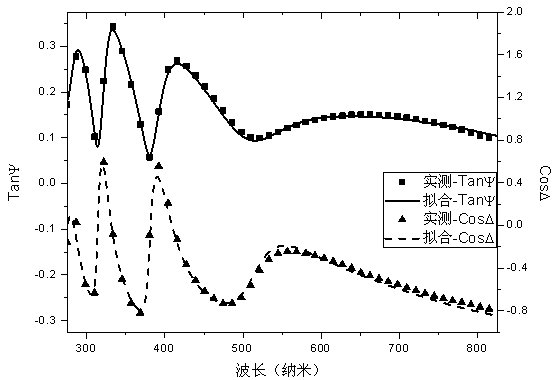

[0030] Choose a SnO 2 :F / SiC x o y For low-emissivity coated glass samples, 0M and tanΨ M , the spectral range is 275nm to 825nm, and the incident angle is set to 58°; it is generated by ellipsometric parameters and established models and The specific model is as follows:

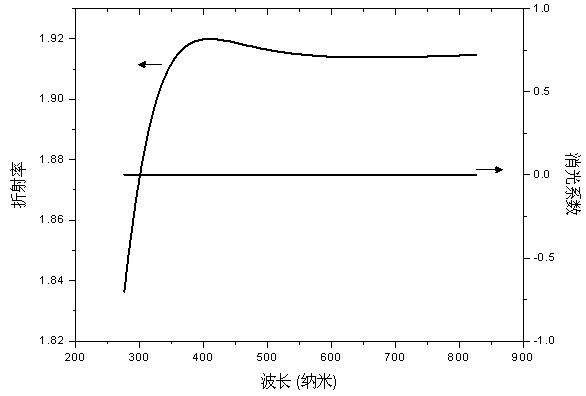

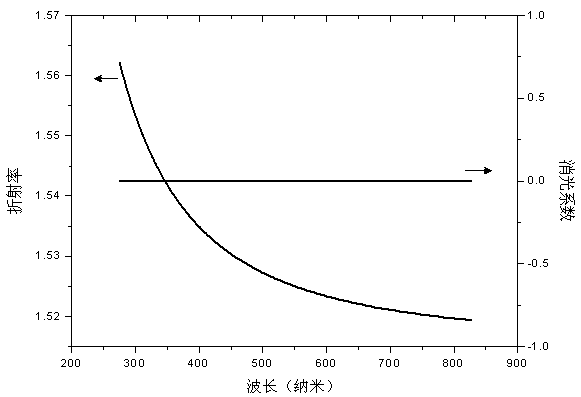

[0031] Establish a five-layer film structure model: the five-layer film structure is recorded as SiC from bottom to top on the glass substrate x o y +Na+ layer, pure SiC x o y layer, transition layer, SnO 2 :F functional layer and rough surface layer, the initial film thickness of each layer is from SiC x o y +Na + Layer up is denoted as d 10 =15nm, d 20 =50nm, d 30 =15nm, d 40 =300nm and d 50 =30nm;

[0032] Establish the corresponding dispersion model: SiC x o y +Na + initial layer and Described by the Cauchy dispersion equation, the initial value is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com