Automatic analyzer for dissolved gas in insulating oil

A technology for dissolved gas analysis and insulating oil, applied in the field of gas analyzers, can solve the problems that insulating oil chromatographic analysis equipment cannot achieve automatic analysis, high labor intensity, and low repeatability of analysis results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

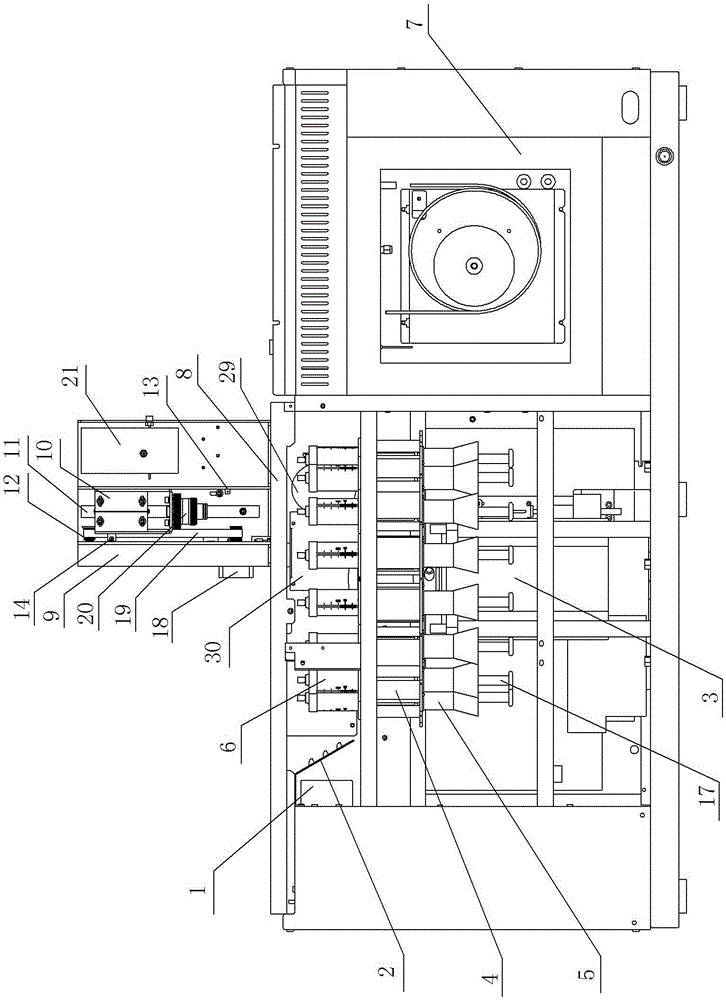

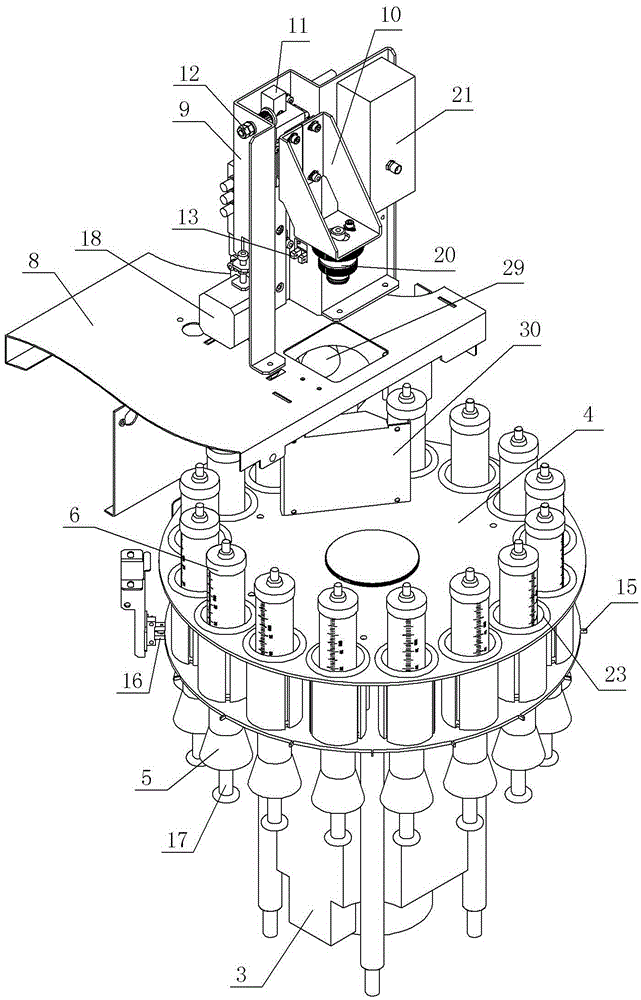

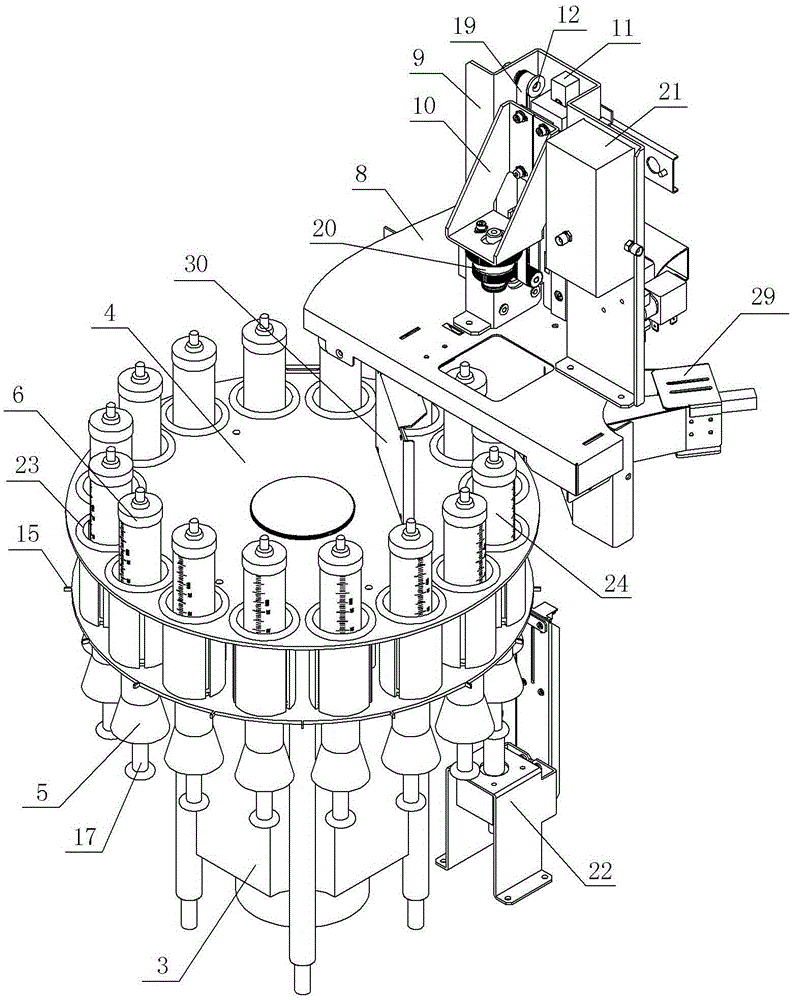

[0038] See Figure 1 ~ Figure 6 In the figure, the automatic dissolved gas analyzer for insulating oil contains a degassing mechanism, an automatic sampling mechanism, a chromatographic mechanism 7 and a circuit control part. The degassing mechanism contains a degassing disc 4, a degassing motor 3, and a degassing disc photoelectric The switch 16, the background light source 30 and the camera 29, the degassing disc 4 is a horizontally arranged turntable, the shaft of the degassing disc 4 is connected with the shaft of the degassing motor 3, and the upper surface of the degassing disc 4 is evenly arranged with 16 vertical A straight syringe placement through hole 23 is connected to the lower part of each syringe placement through hole 23 with a vertical fixed tube sleeve 5, the syringe placement through hole 23 is in communication with the fixed tube sleeve 5, and the bottom of the fixed tube sleeve 5 is provided with a The piston rod through hole, when the end of the piston ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com