Whole pass sampling tester

A tester and full-bore technology, applied in the direction of wellbore/well components, earthwork drilling and production, etc., can solve the problems of lower test efficiency, failure to obtain full-open drill string switch well pressure, low work efficiency, etc., and achieve expansion Use the operating range, improve the test success rate, and avoid the effect of blocking flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

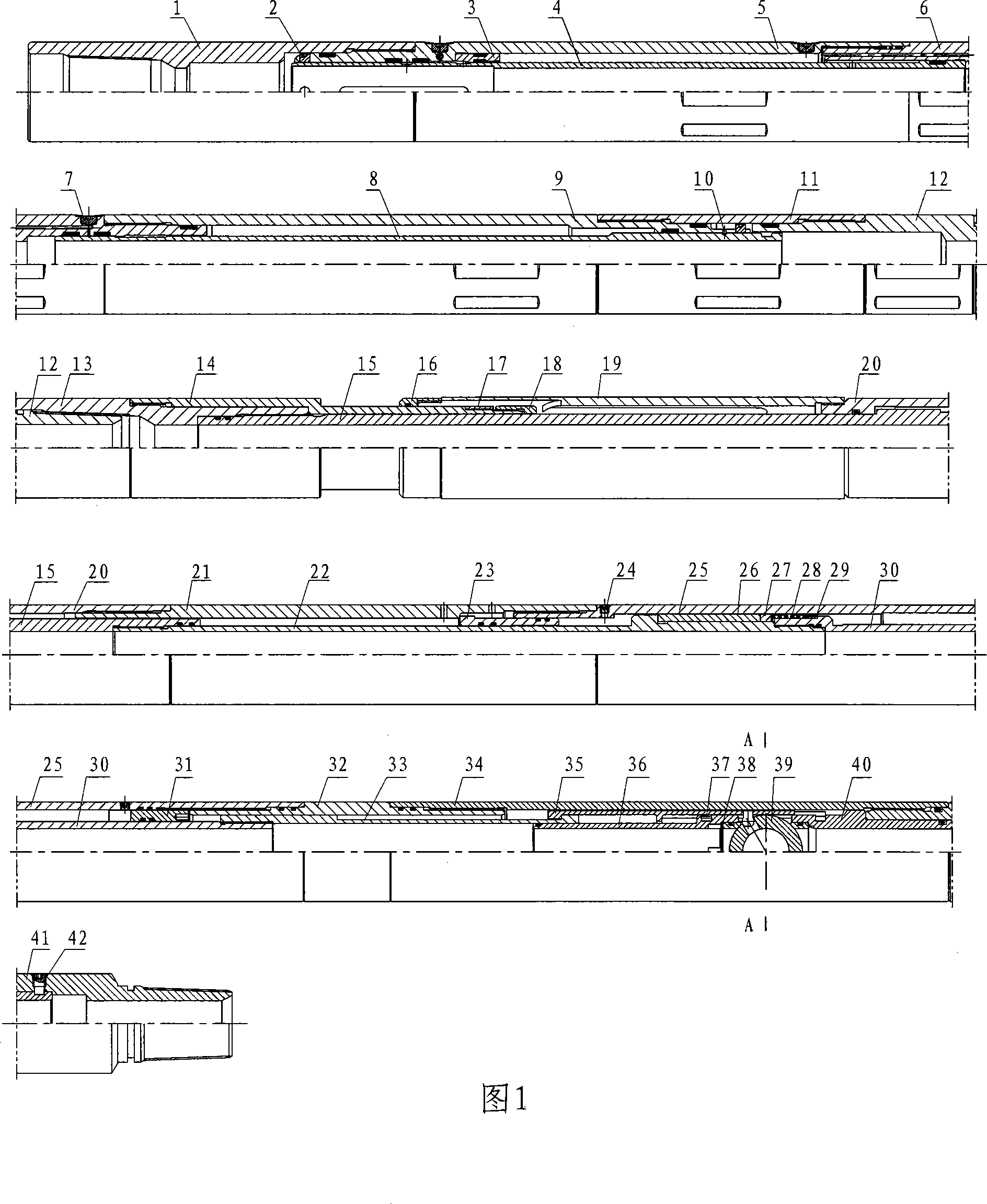

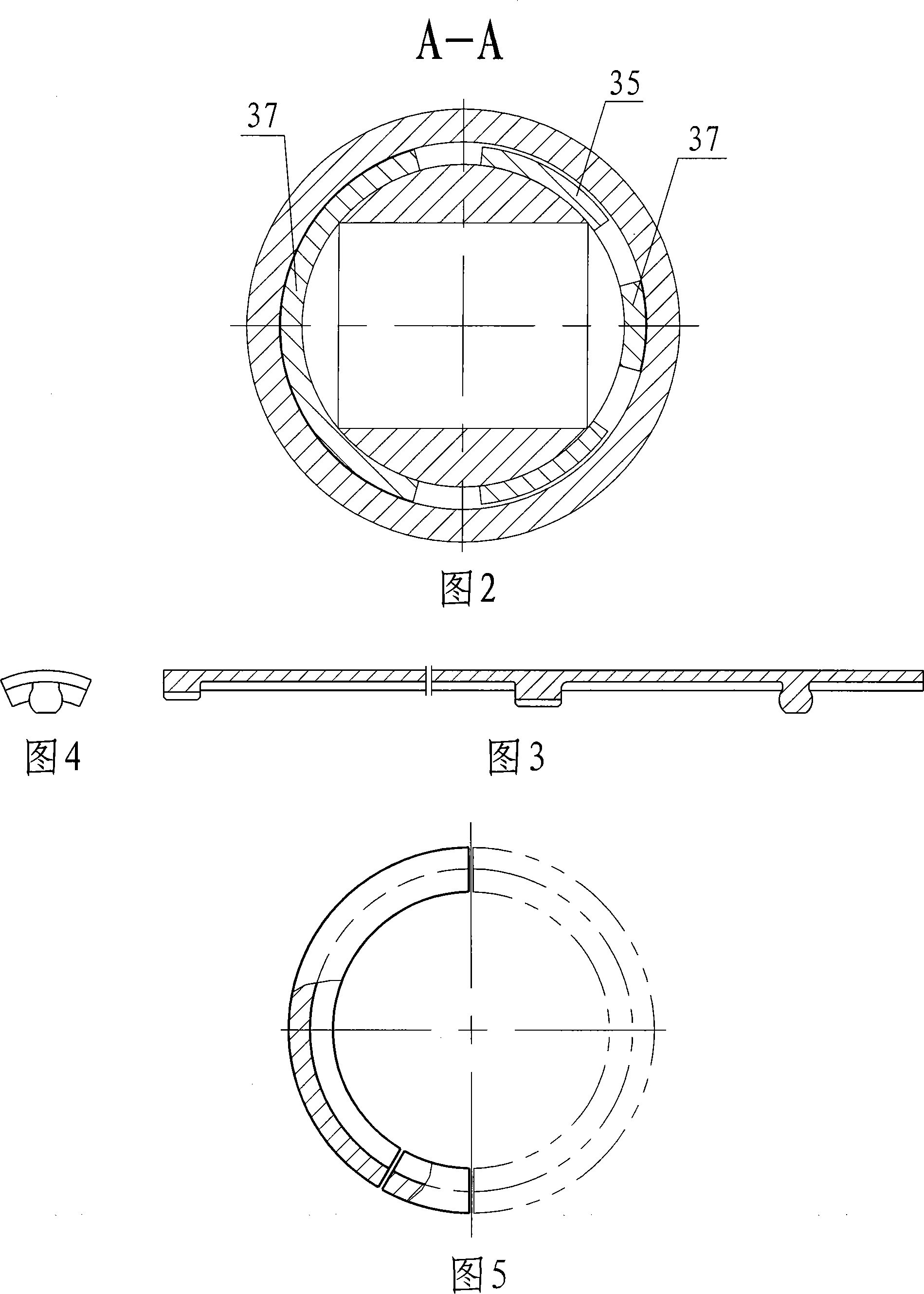

[0019] As shown in Figures 1 to 5, the present invention includes a sampling mechanism, a transposition mechanism, a time-delay mechanism and a ball valve mechanism. The ball valve mechanism is connected to the lower end of the spindle, and the sampling mechanism, transposition mechanism, The mechanism and the time-delay mechanism are connected in sequence, and the mandrel can reciprocate up and down in each mechanism to drive the switch of the ball valve mechanism.

[0020] The delay mechanism is composed of an upper connecting outer cylinder 21, an upper spindle 22, a compensating piston 23, a delay outer cylinder 25, a delay valve 26, a lower spindle 30 and a sealing retaining ring 31. The outer sleeve of the upper and lower spindles 22, 30 of the delay mechanism is provided with a delay outer cylinder 25, one end of which is threadedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com