Horizontal effective ground stress testing method and device

A stress testing and effective technology, applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of inaccurate principal stress direction, low test success rate, and increased test cost, which is easy to implement and conducive to popularization. Application, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

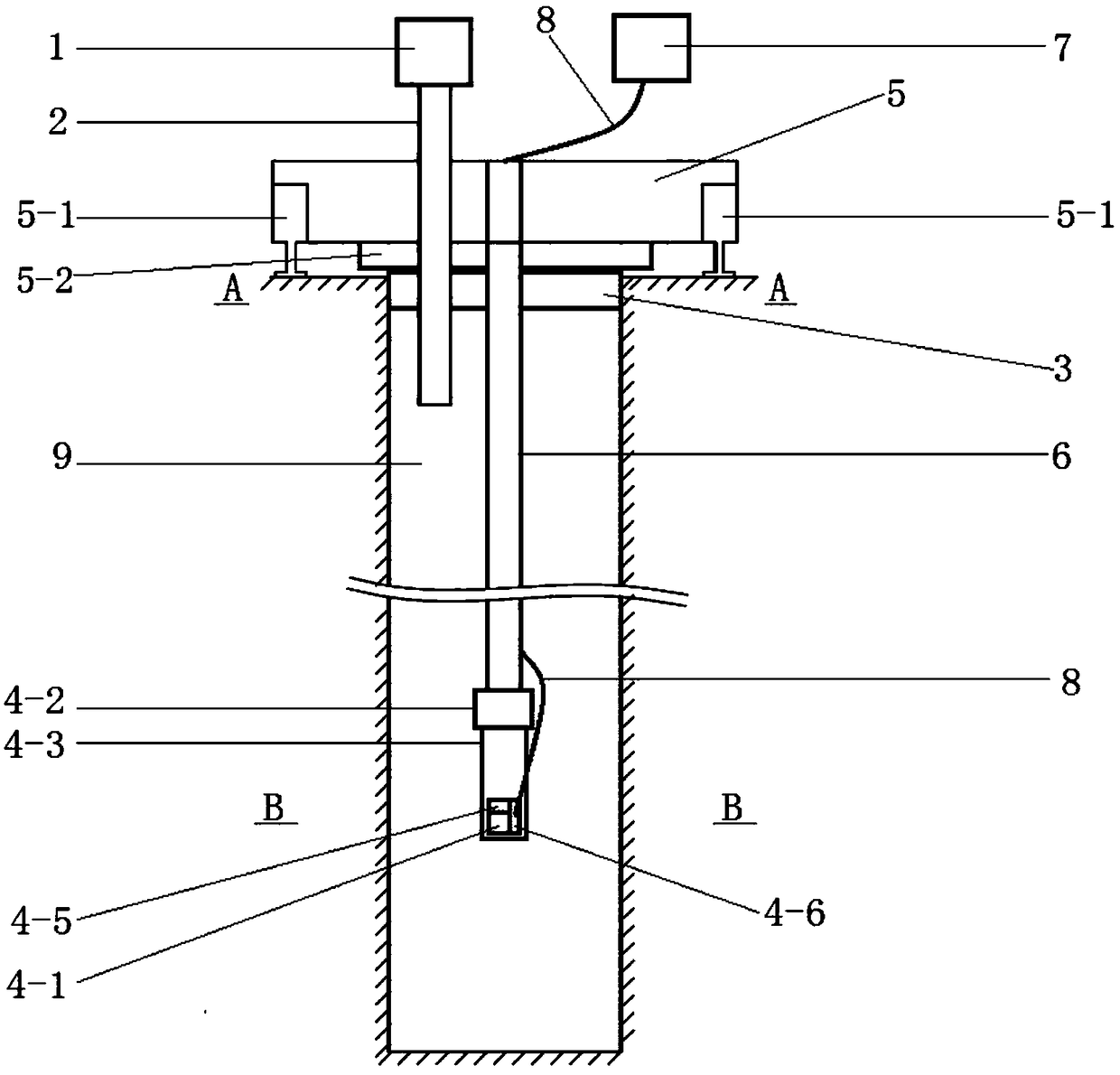

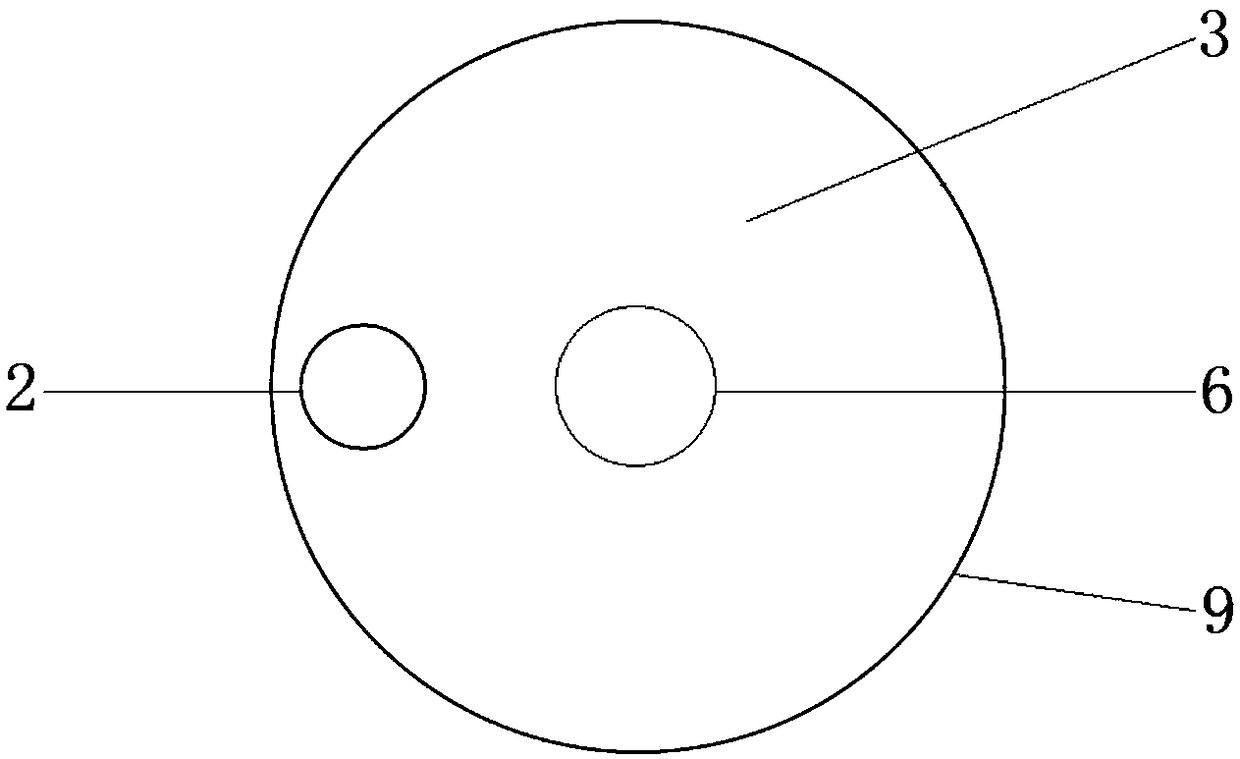

[0035] In this embodiment, a horizontally effective stress testing device is provided, and the structural diagram of the device is as follows Figure 1~3 As shown, it includes a grouting device 1, a grouting pipe 2, a borehole seal 3, a borehole shape and pressure measurement system, a support fixture 5, a connecting rod 6 and a computer processing system 7, and the borehole seal 3 has a thickness of 150 mm. 1. A rubber seal whose diameter matches the inner diameter of the borehole, and a round hole whose diameter matches the outer diameter of the grouting pipe and the connecting rod. The connecting rod is formed by threading a plurality of hollow drill pipes.

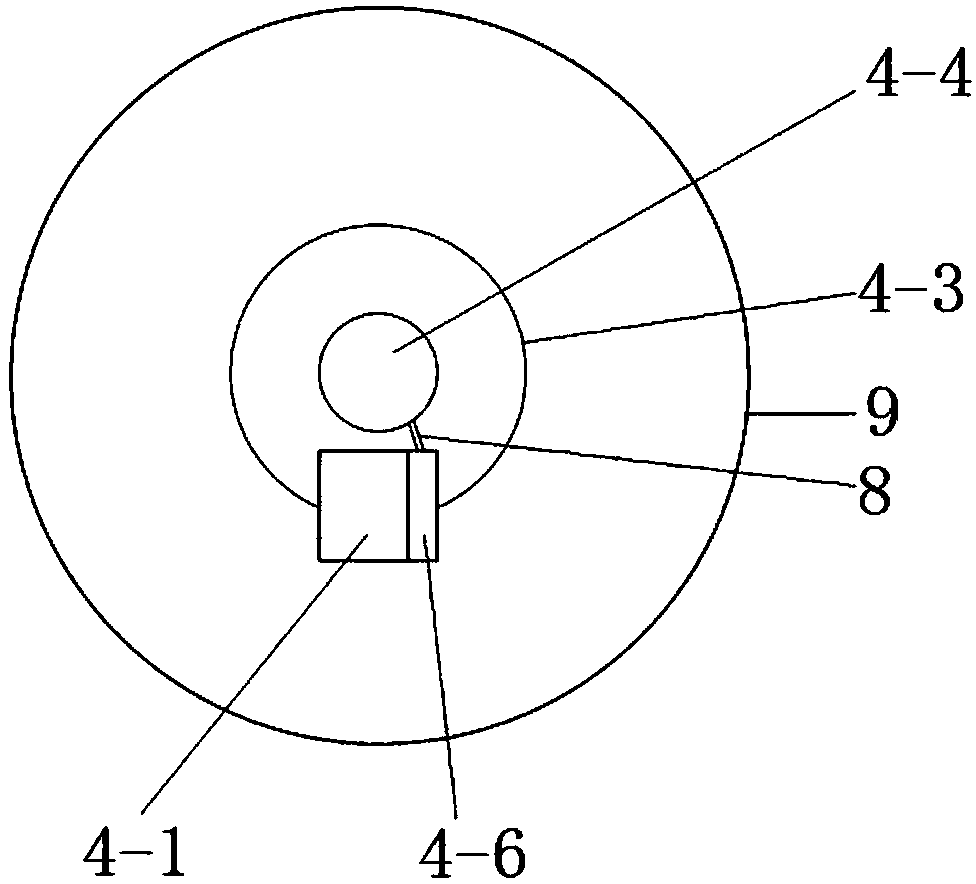

[0036] The drilling shape and pressure measurement system includes a multi-scale phase laser rangefinder 4-1, a motor 4-2, a detection axis 4-3, a three-dimensional electronic compass 4-4, a pressure sensor 4-5 and a data integration chip 4-6 , the motor 4-2 is powered by two sets of rechargeable Ni-MH batteries with r...

Embodiment 2

[0040] In this embodiment, a horizontally effective stress test method is provided, which uses the horizontally effective stress test device in Example 1 for testing, and the process schematic diagram of the method is as follows Figure 4 As shown, the steps are as follows:

[0041] ① Drill a hole perpendicular to the horizontal plane on the target rock mass, place the support bracket above the drill hole, adjust the height of the support feet so that the support bracket is in a horizontal state, connect the drilling shape and the motor of the pressure measurement system to the Rod connection, adjust the length of the connecting rod, send the connecting rod installed with the drilling shape and pressure measurement system into the borehole so that the drilling shape and pressure measurement system are immersed in the drilling fluid remaining in the drilling hole when drilling the hole, When the drilling shape and the pressure measurement system reach the target depth, fix the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com