High-temperature and high-pressure hydrofracturing clamp holder and test method thereof

A hydraulic fracturing, high temperature and high pressure technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc., can solve the problems of cumbersome operation, high cost, liquid leakage, etc., and achieve low test cost, Easy to operate and high test success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

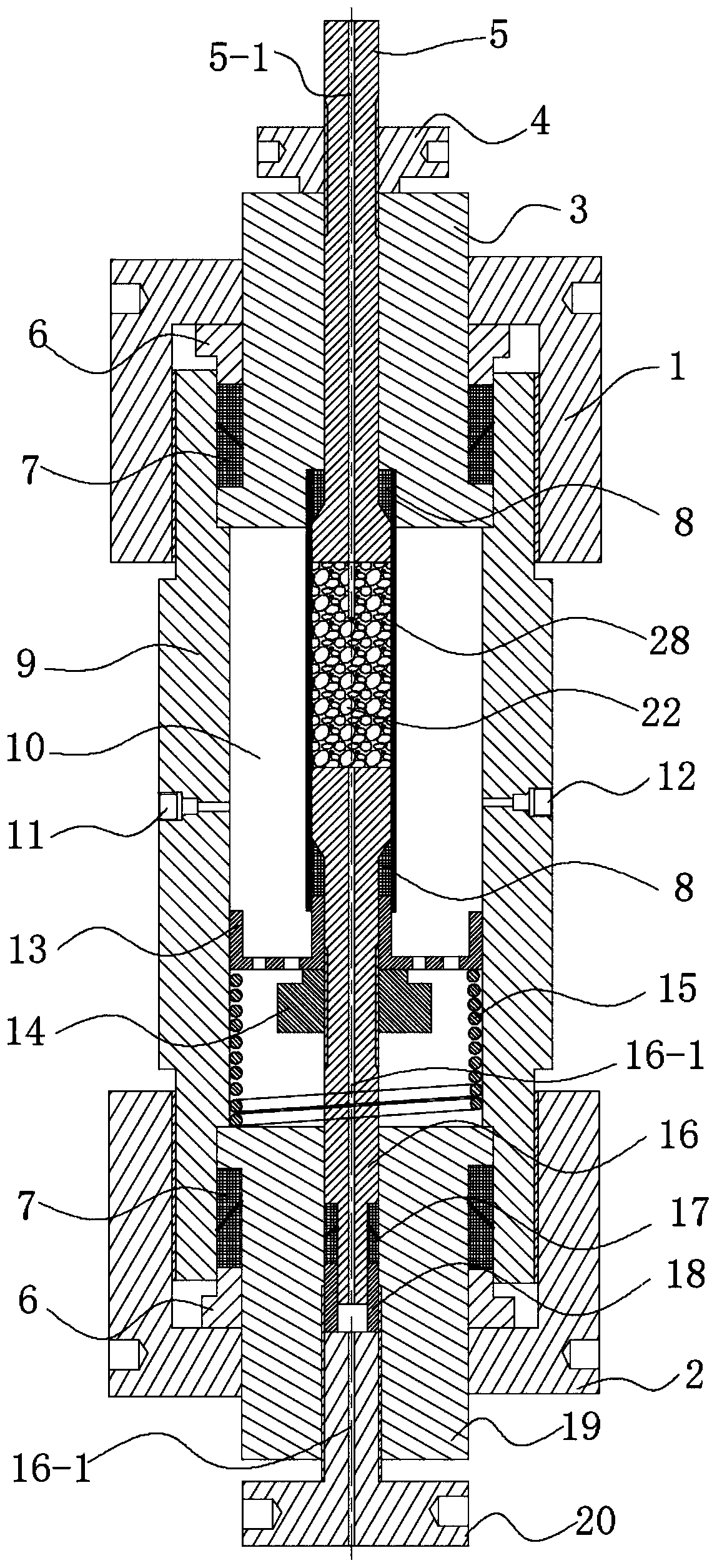

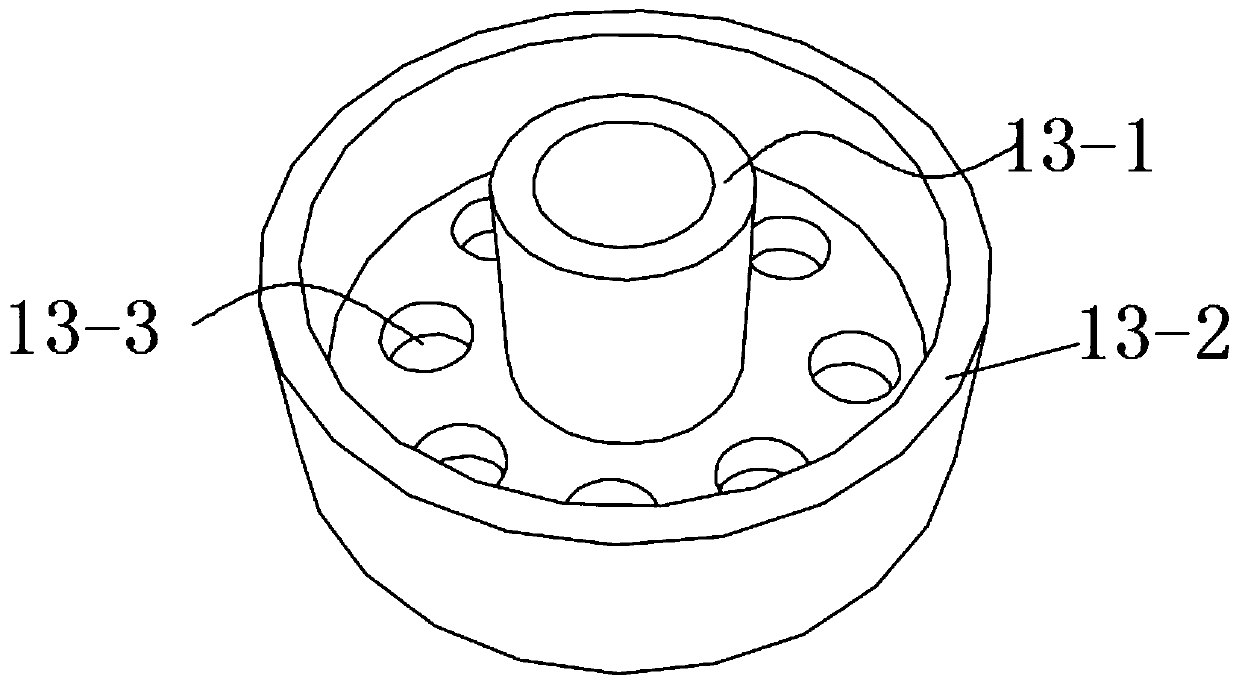

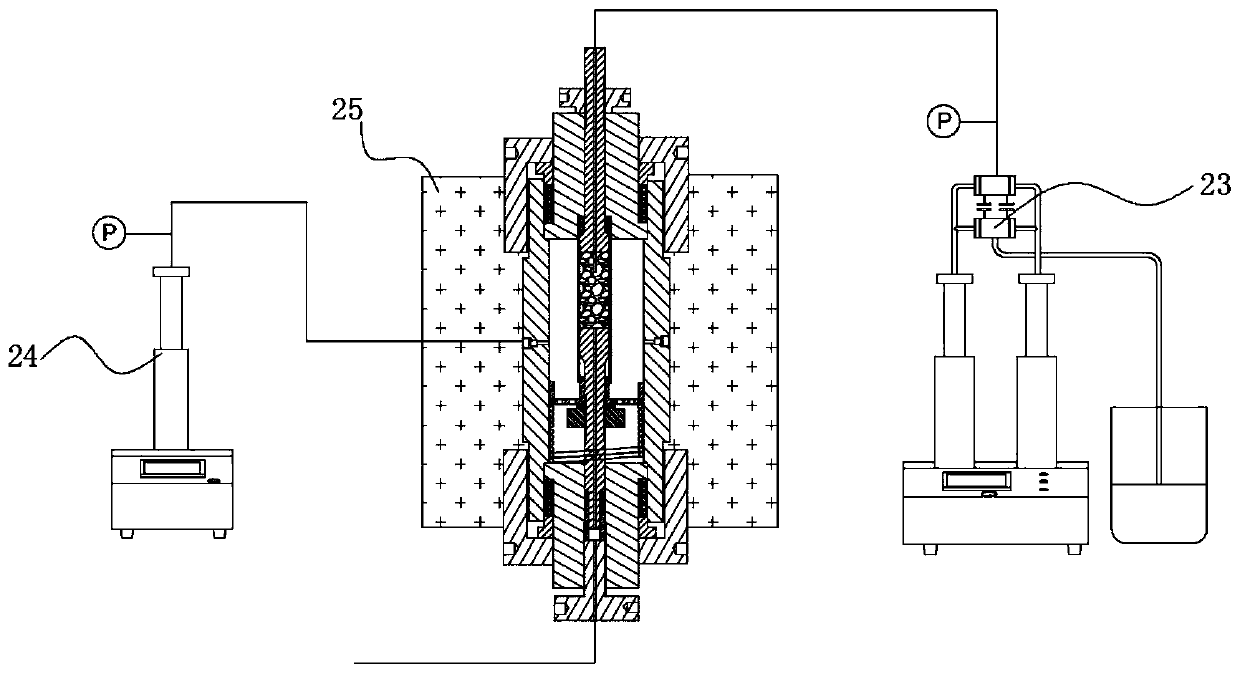

[0034] Such as figure 1 As shown, the high temperature and high pressure hydraulic fracturing holder includes a test cylinder 9, an upper installation part of the cylinder, a lower installation part of the cylinder and an inner installation part of the cylinder.

[0035] The test cylinder 9 is a cylindrical structure that penetrates up and down. The test cylinder 9 is provided with an oil injection hole 11 and an oil outlet 12 that penetrate the cylinder wall along its radial direction. The inner chamber of the test cylinder 9 includes The confining pressure chamber section 10 arranged in the middle in the direction and the large diameter section symmetrically arranged at the upper and lower ends of the confining pressure chamber section 10 form an upper positioning step and a lower positioning step between the large diameter section and the confining pressure chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com