Patents

Literature

47 results about "Thermal mechanical coupling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrochemical-thermal-mechanical coupling model of lithium ion battery and modeling method

InactiveCN110457742ADelay agingImprove performanceComputational theoretical chemistrySpecial data processing applicationsElectrochemical responseCyclic process

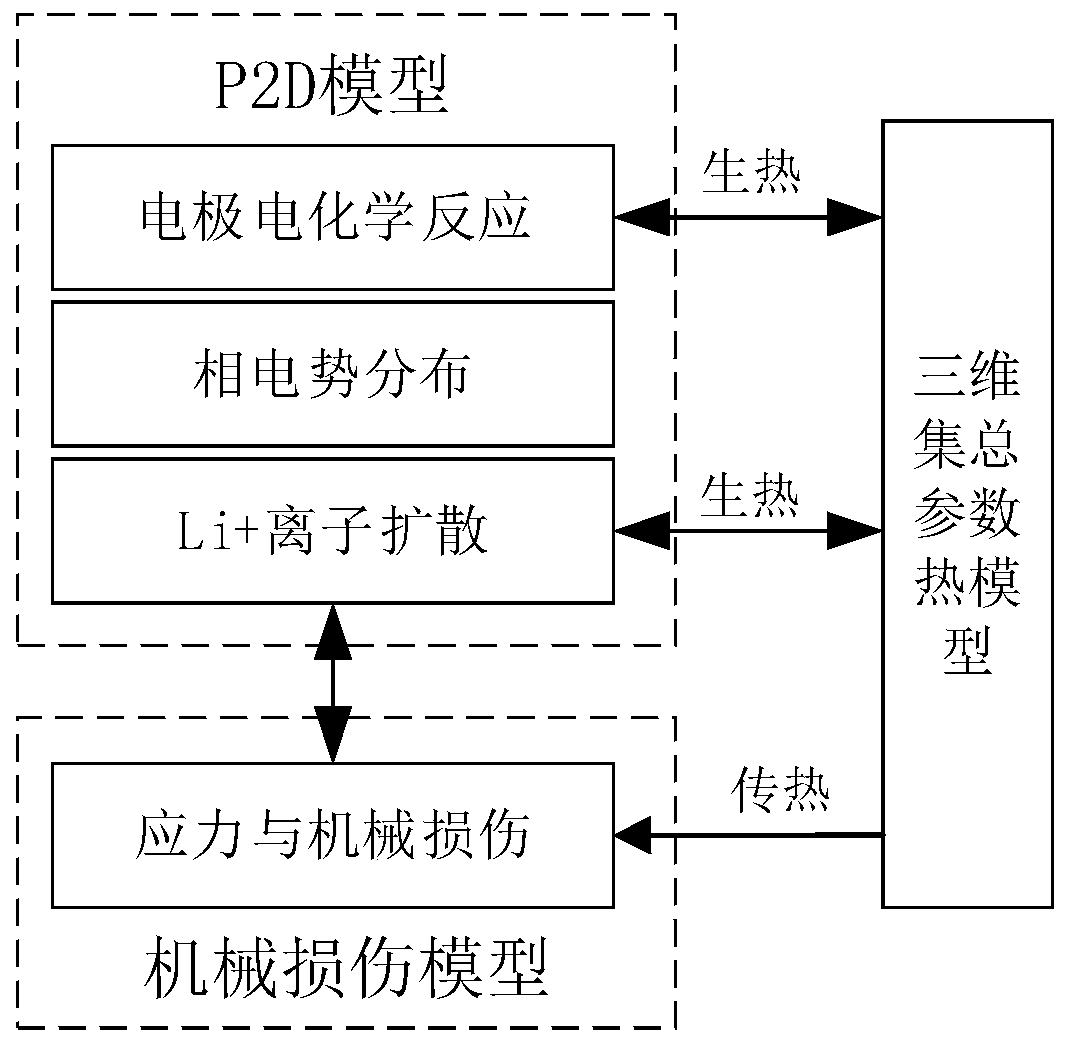

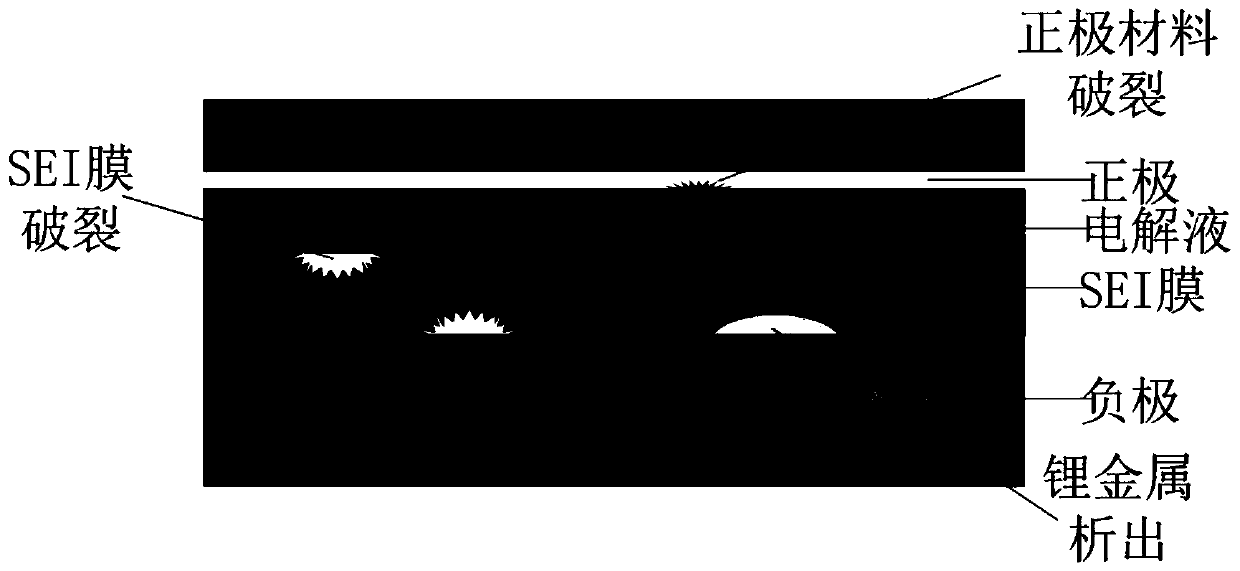

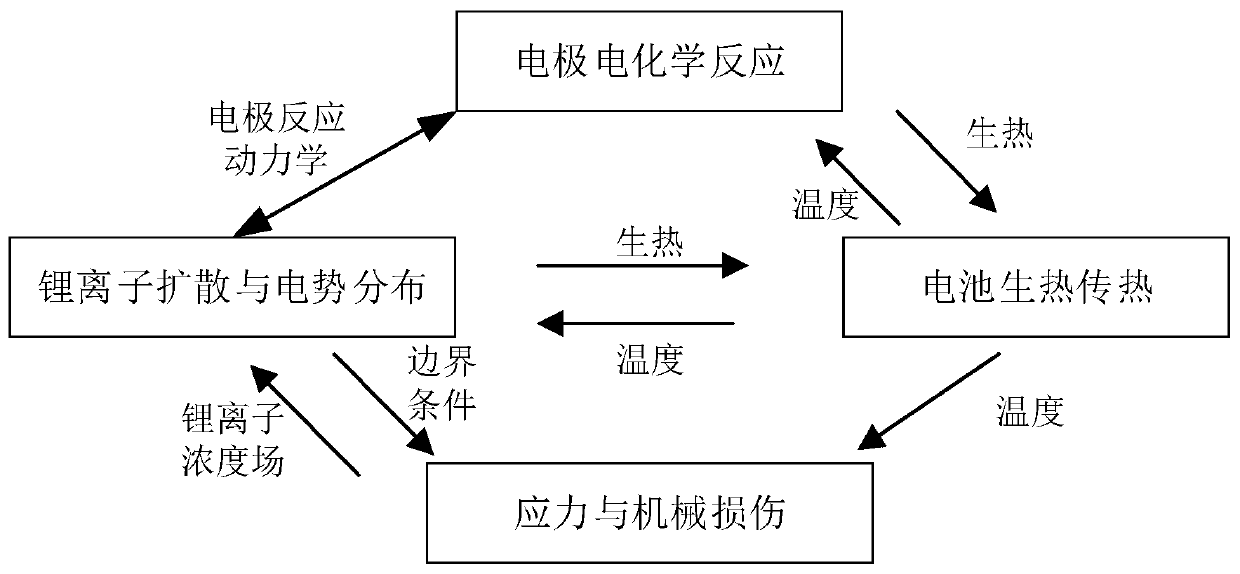

The invention relates to an electrochemical-thermal-mechanical coupling model of a lithium ion battery and a modeling method. Based on a classic electrochemical quasi-two-dimensional model of the lithium ion battery, heat generated by electrochemical reaction of the battery in use is introduced; meanwhile, a three-dimensional lumped parameter thermal model is adopted to simulate temperature changein the battery cycle process, a mechanical damage model of the battery in the whole life cycle is established to describe the influence of ion diffusion induced stress on the service life of the battery in the charging and discharging process of the battery, and a dynamic parameter compensation method is utilized to couple the models. The lithium ion battery electrochemical-thermal-mechanical coupling model generated by using the model building method can be used for estimating and predicting the monomer temperature of a battery thermal management system (BTM) and researching the physical property change and thermal runaway of the battery; a basis is provided for research on the performance evolution law of the lithium ion battery, and the method has important significance in slowing downbattery aging and prolonging the service life.

Owner:BEIHANG UNIV

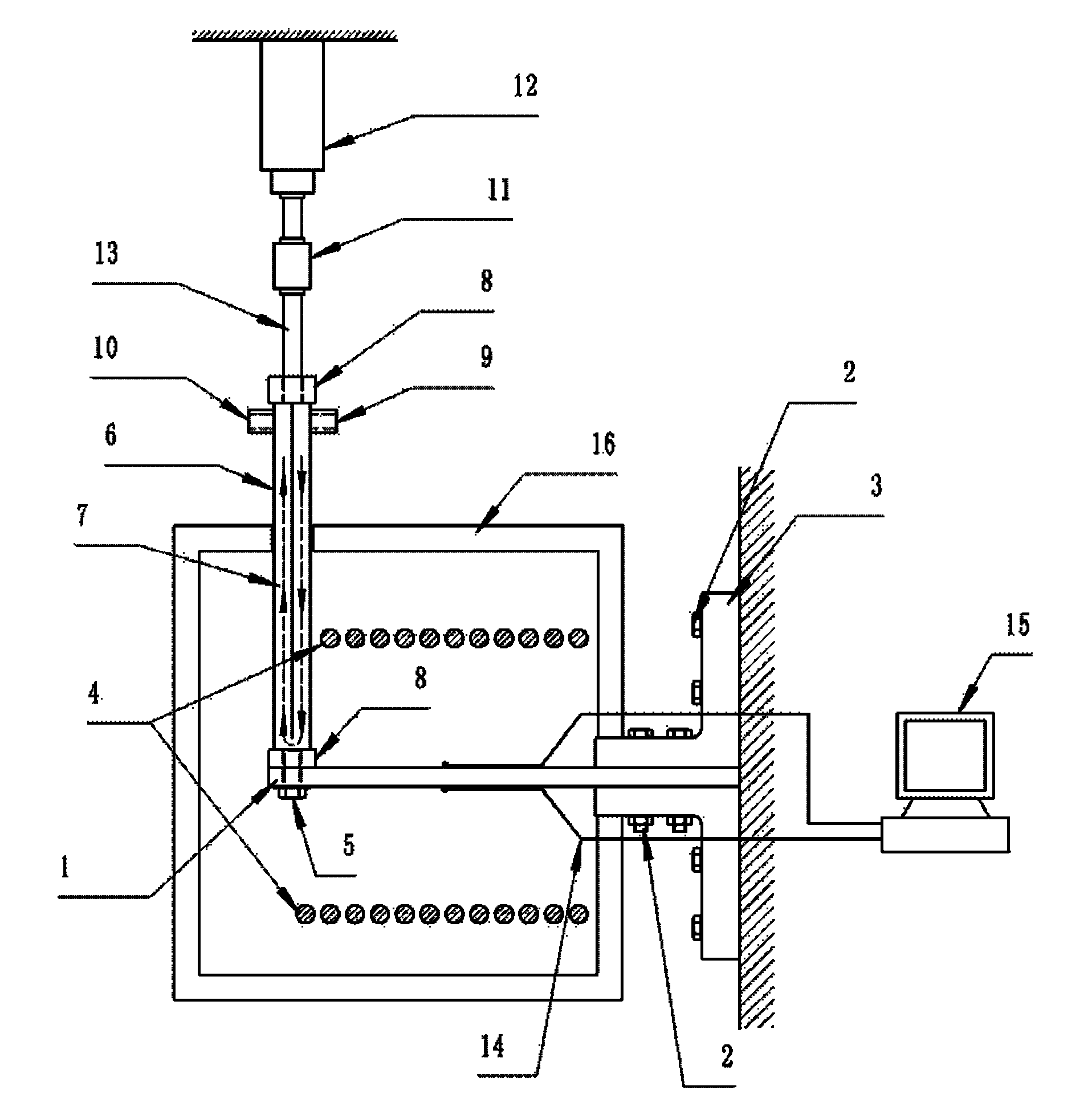

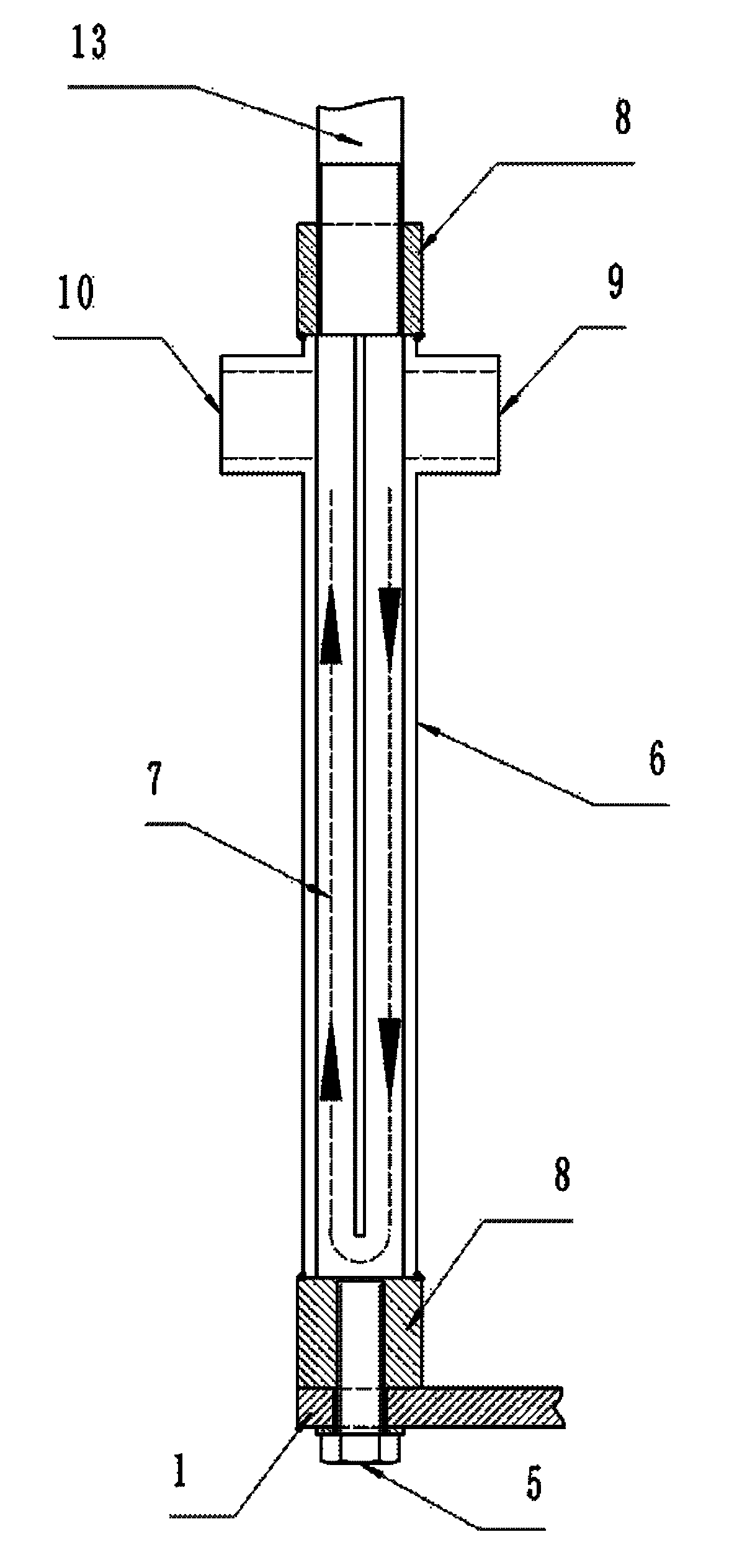

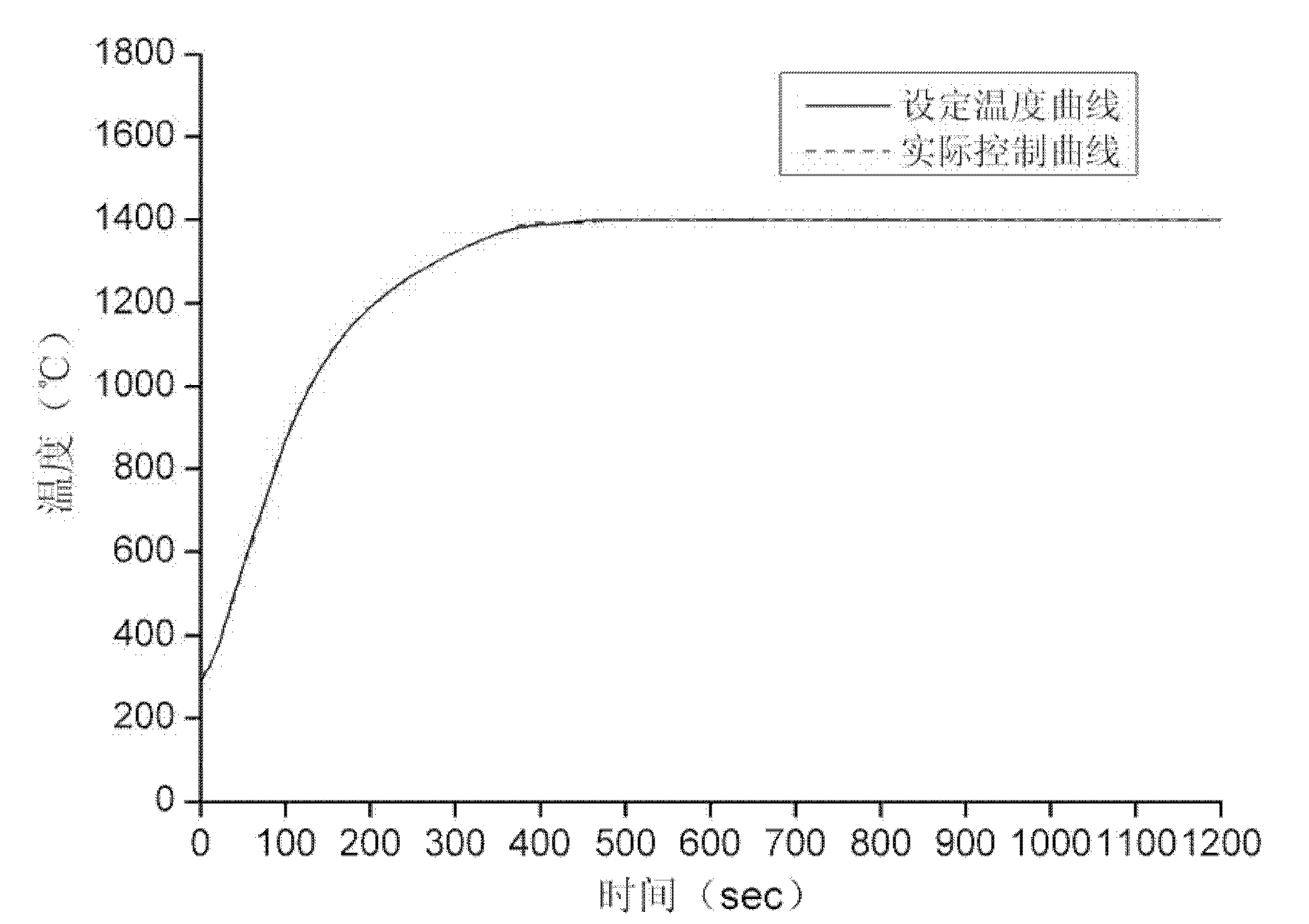

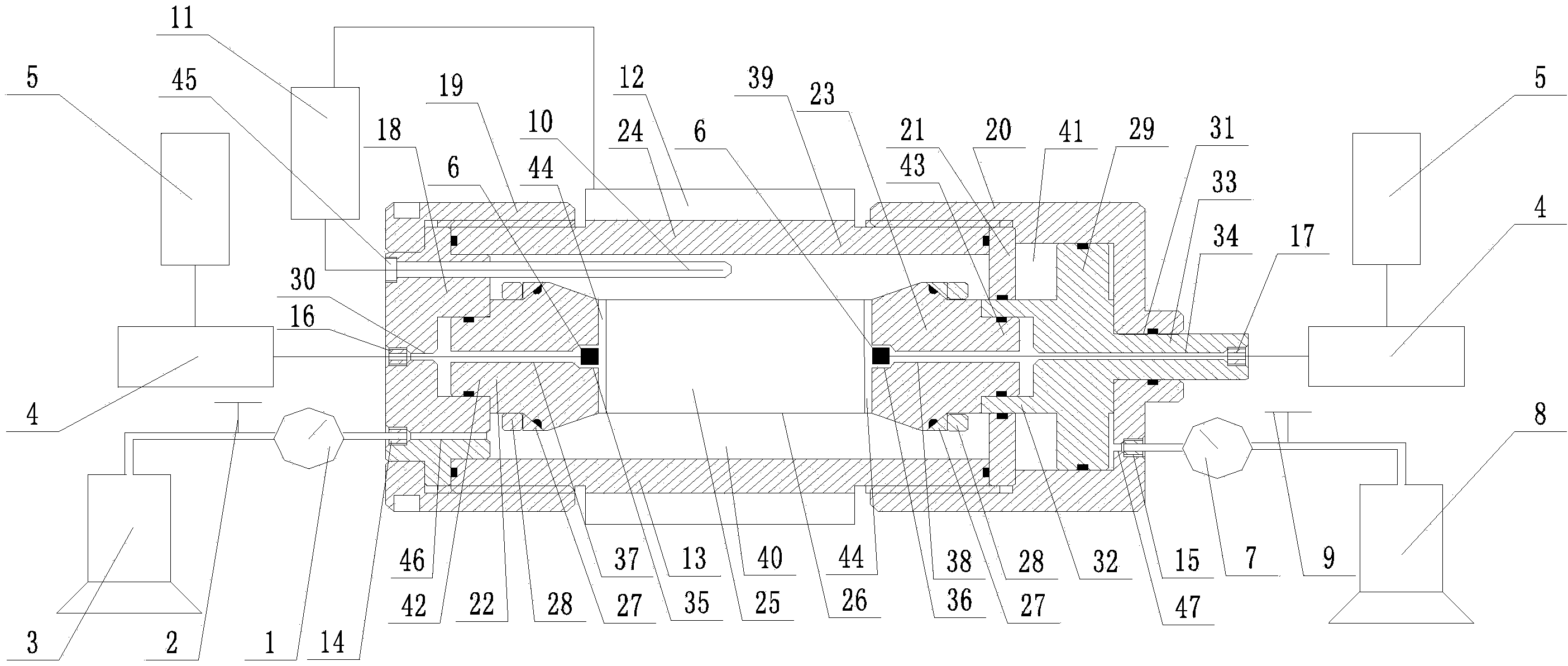

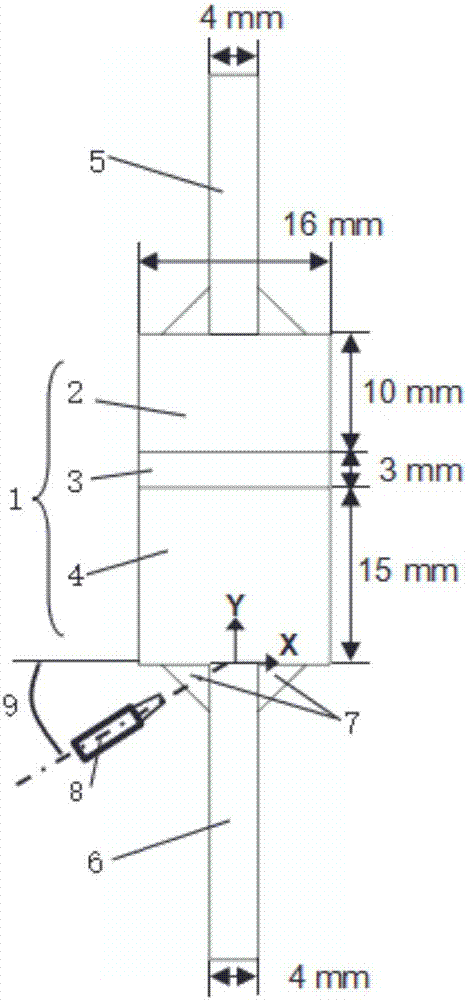

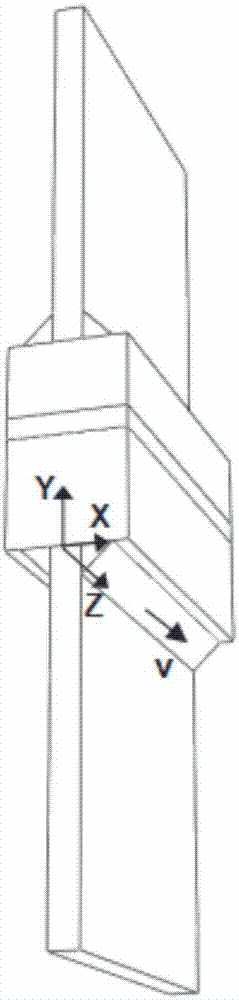

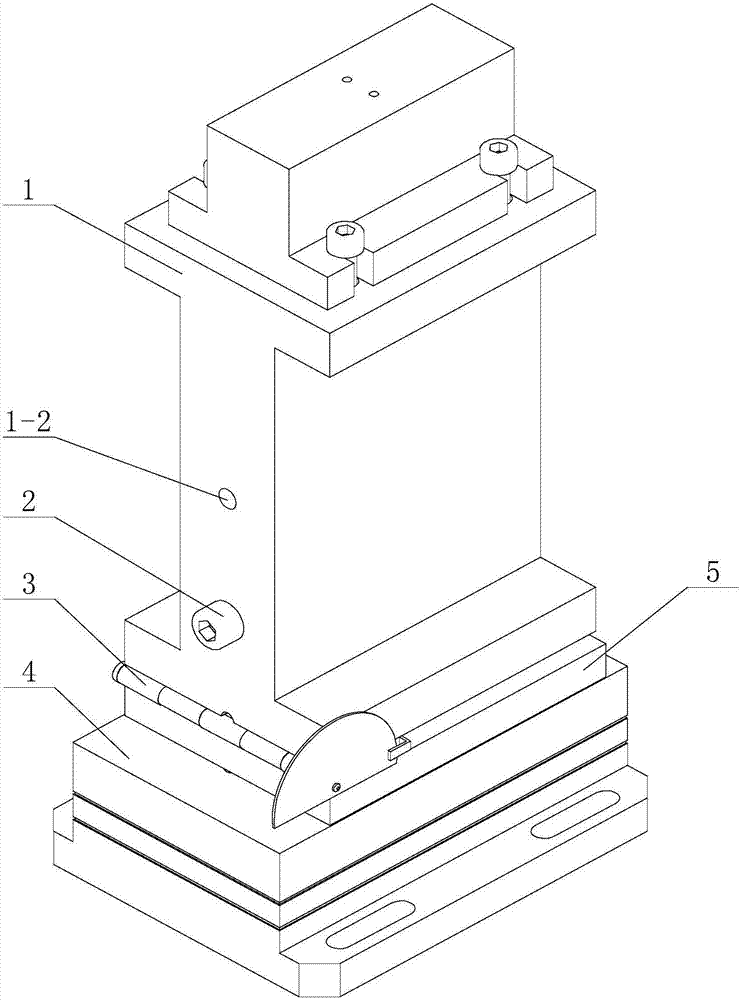

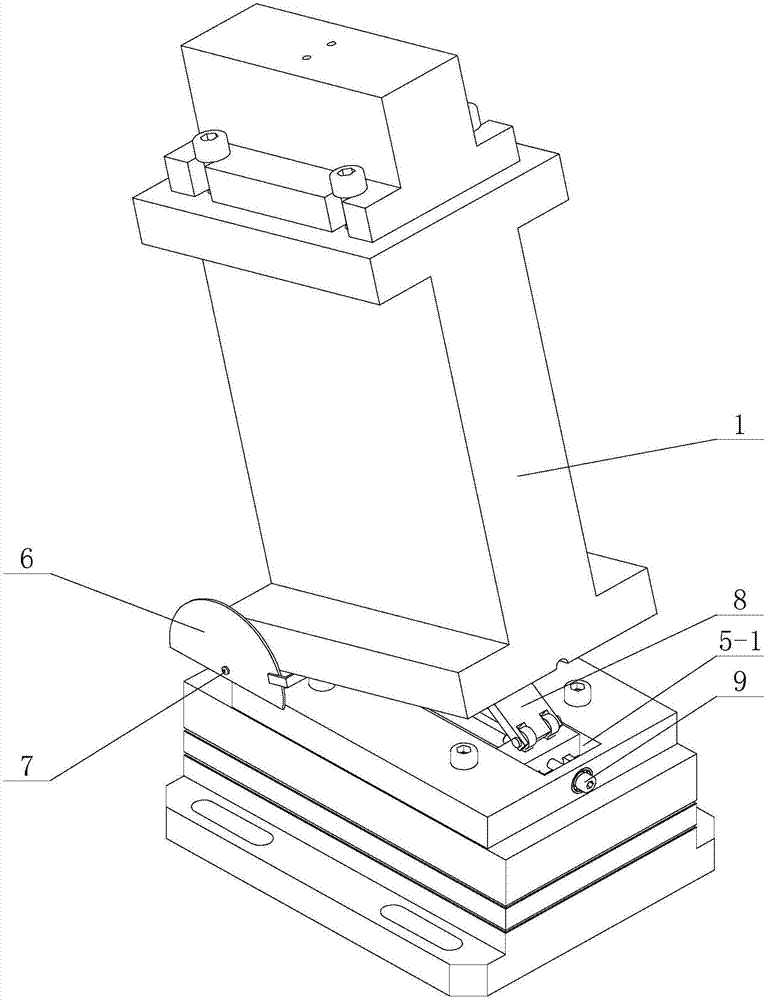

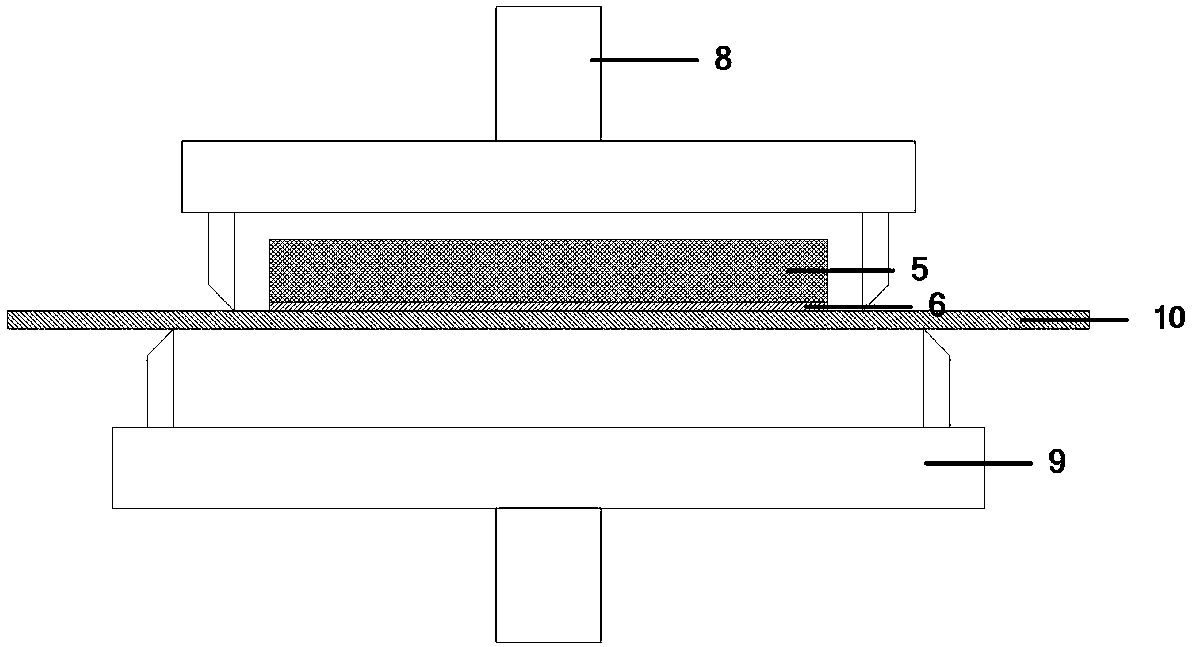

1400°C high temperature thermal-mechanical coupling test device for the airfoil structure of hypersonic aircraft

InactiveCN102262099AThermal-mechanical coupling test completedReduce the temperatureMachine part testingMaterial thermal analysisEngineeringActuator

The invention discloses a 1400-DEG C high-temperature thermal-mechanical coupling test device for the aerofoil structure of a hypersonic vehicle, which comprises a test sample of the aerofoil structure of the hypersonic vehicle, a silicon-molybdenum heating array, a water-cooled metal-loading component, a U-shaped water-cooled channel, a force sensor, a hydraulic actuator, a temperature sensor and a computer. Because the water-cooled metal-loading component is designed into a U-shaped hollow structure, the problems of high-temperature softening and deformation existing in the metal-loading component at 1400 DEG C are solved by using a method of cooling the inside of the metal loaded component with flowing liquid, the high-temperature (up to 1400 DEG C) thermal-mechanical coupling test on the aerofoil structure can be realized, and the ultimate strength of the aerofoil structure in high-temperature thermal-mechanical complex environment and other important parameters can be obtained, thereby providing a reliable basis for the safety design of a hypersonic vehicle structure in high-speed, high-temperature thermal-mechanical coupling environments.

Owner:BEIHANG UNIV

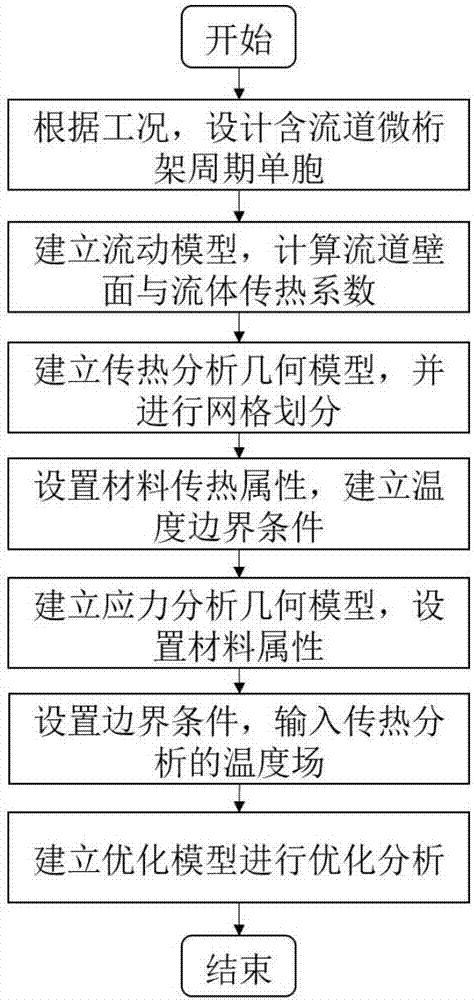

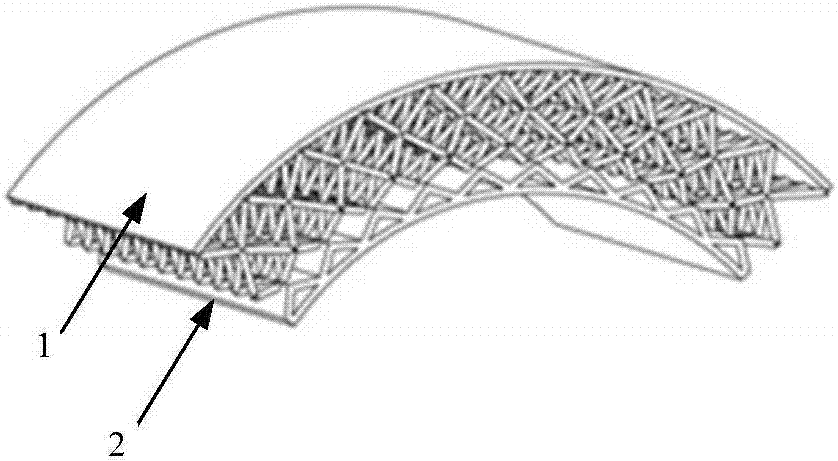

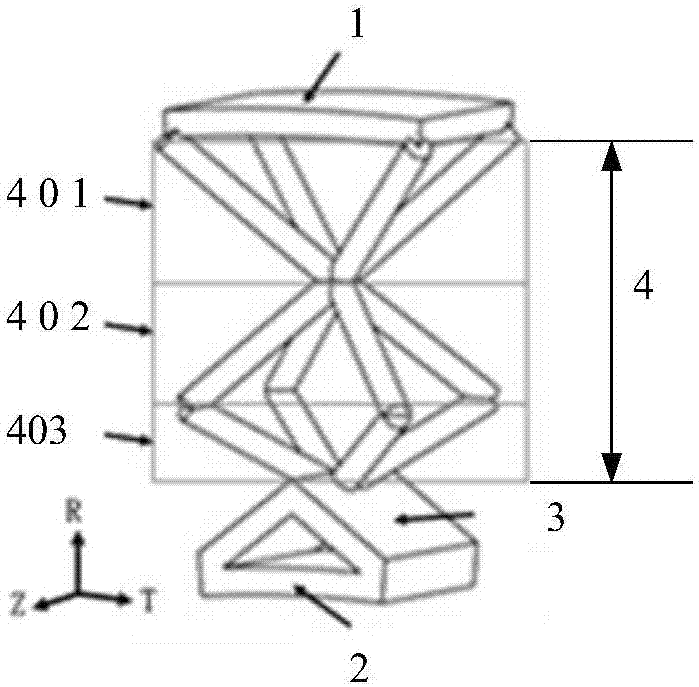

Micro-truss structure carrying and thermal protection structure multi-objective optimization method

InactiveCN108009336ASimple designStable internal working environmentGeometric CADDesign optimisation/simulationAviationMaterial Design

The invention discloses a micro-truss structure carrying and thermal protection structure multi-objective optimization method, and belongs to the field of spacecraft instrumentation overall design andmultifunctional structure material design. A flow channel is introduced into a micro-truss sandwich structure, multi-objective optimization of temperature and stress is realized by thermal transfer and force transfer coupling calculation, and final design meets a design process and the lightest front edge structure of a design boundary. The problem of thermal mechanical coupling under practical working conditions is taken into full consideration, the influence of the temperature on strength is introduced, processing technology boundary conditions are considered, and optimum structural designis realized by an optimization algorithm. The method is simple and effective, optimum design can be realized by small calculated amount, and time and cost consumed by trial and errors are greatly reduced.

Owner:BEIHANG UNIV +2

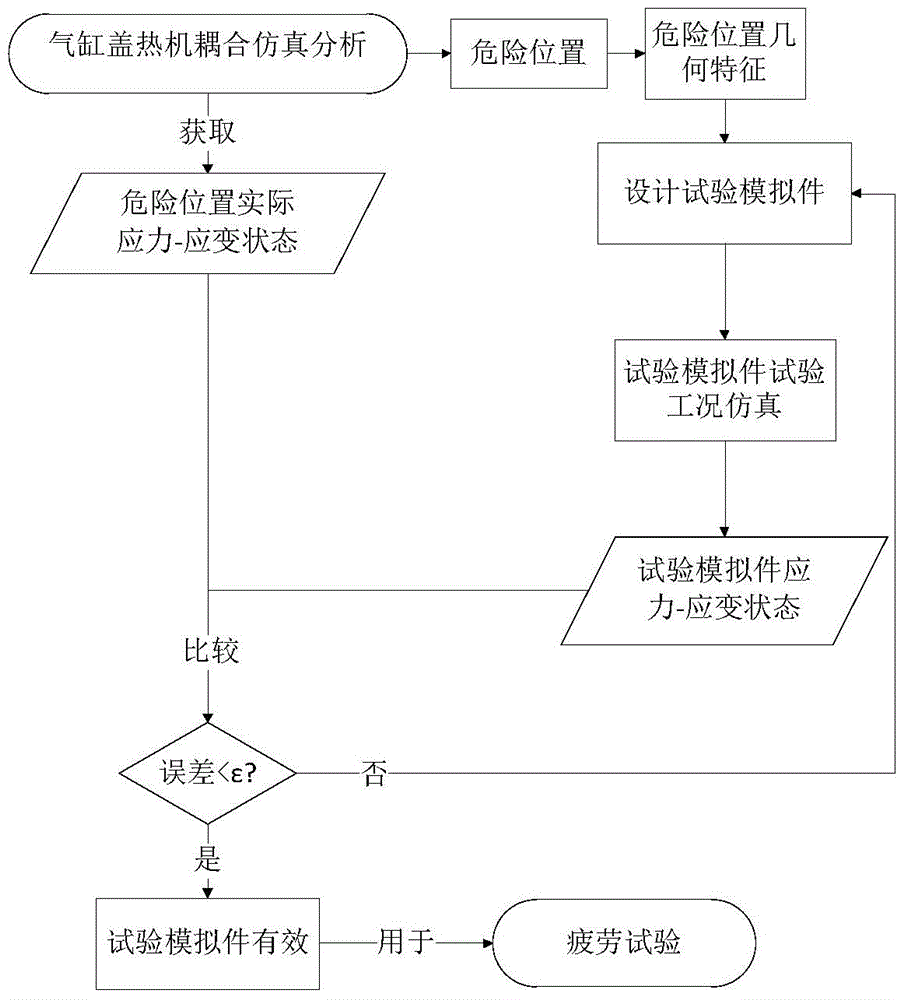

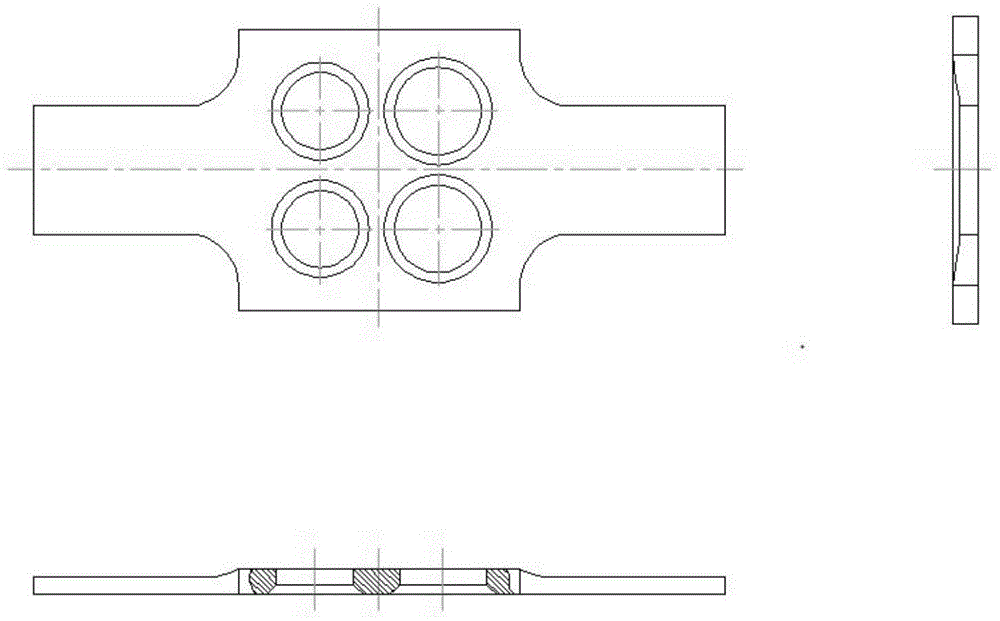

Fatigue test method of cylinder cover simulating test specimen

ActiveCN104792632AGuaranteed accuracyShorten the test cycleMaterial strength using repeated/pulsating forcesPrincipal stressEngineering

The invention provides a fatigue test method of an engine cylinder cover simulating test specimen. The fatigue test method comprises the following steps: through a finite element simulation method, computing three principal stress-strain values at different dangerous positions of an entity cylinder cover; establishing a test specimen model; setting the maximum cyclic load value required to be exerted to a unidirectional tension and compression test bench; computing three principal stress-strain values at dangerous positions of the test specimen model; comparing the three principal stress-strain values at the dangerous positions of the test specimen model with those of the entity cylinder cover respectively to determine the final test specimen model; machining and shaping the determined final test specimen model, and then performing fatigue test on the unidirectional tension and compression test bench. According to the fatigue test method, purely mechanical fatigue test replaces thermal-mechanical coupling fatigue test, so that the test period can be greatly reduced, and the test accuracy is ensured to a certain extent.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Steel structure welding deformation analytical method

InactiveCN103177149AQuality improvementReasonable welding processSpecial data processing applicationsEngineeringWelding deformation

The invention relates to a steel structure welding deformation analytical method. The method comprises the steps of a, establishing a computer welded joint model, and enabling the joints with five standards of a flat V-type butt joint, a flat X-type butt joint, a T-joint V-type groove, a T-joint X-type groove and a fillet joint V-type groove to be simplified to be in two forms of a plate butt joint and a T-joint; b, collecting field data; c, carrying out analogue simulation on a finite element of computer thermal mechanical coupling; d, comparing data, and conducting comparison inspection to data obtained through experiments and three-dimensional model analytical data; and e, formulating welding process, and calculating welding residual deformation and stress of the joints by inputting welding parameters such as the welding method, the groove parameter, welding currents, welding voltages and welding speed. By means of the steel structure welding deformation analytical method, welding production processes are simple and direct, subsequent processing and trimming procedures are reduced, working time cost and fuel cost are lowered, production efficiency is improved, and the quality of the welding joints is also greatly improved.

Owner:CHINA 22MCC GROUP CORP

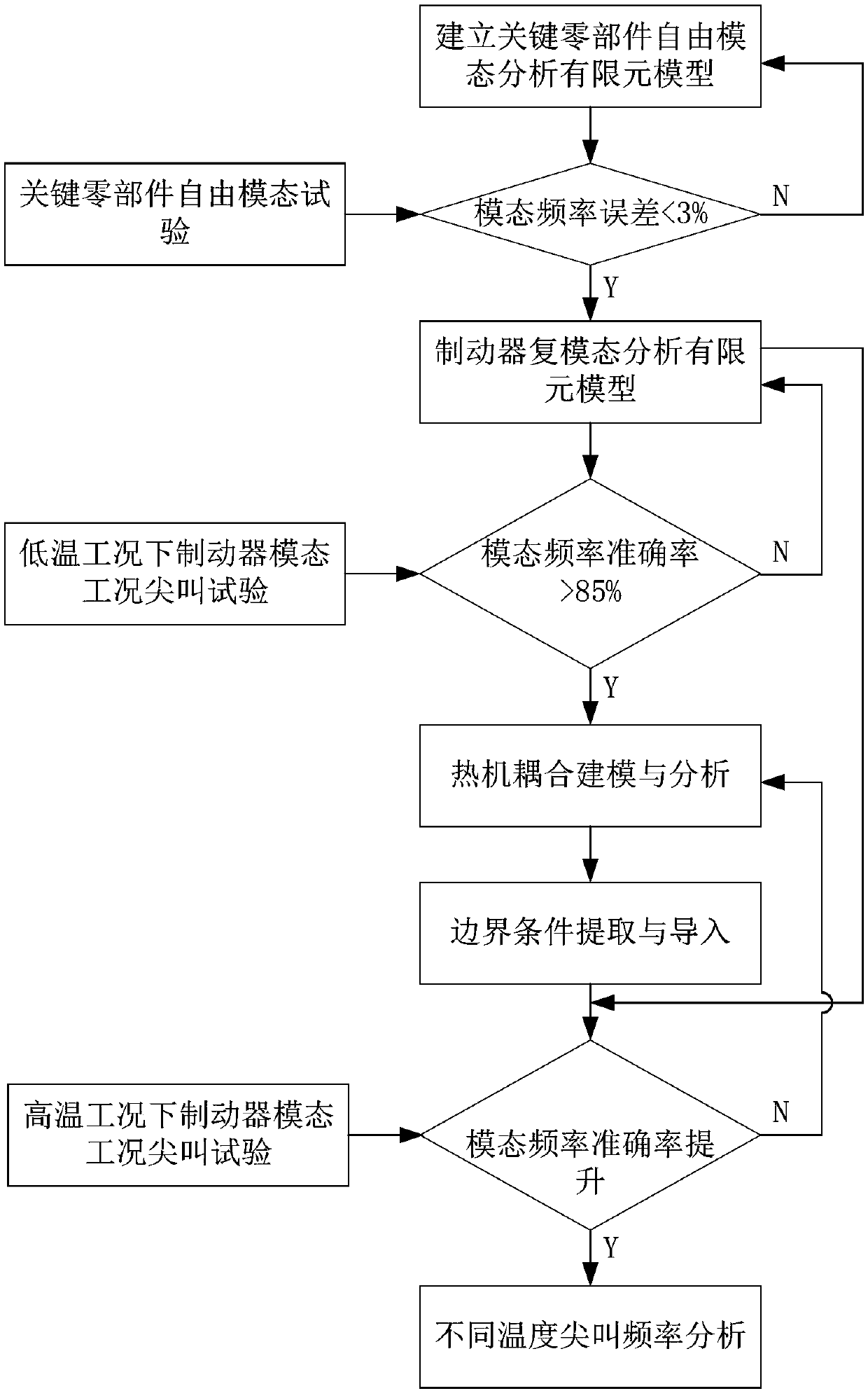

Brake squeal prediction method of considering thermal-mechanical coupling effect

ActiveCN107704644AImprove accuracyHigh precisionGeometric CADDesign optimisation/simulationModal testingElement model

The invention relates to a brake squeal prediction method of considering a thermal-mechanical coupling effect. The method includes the following steps: A, establishing a finite element model of free modal analysis of key parts; B, carrying out free modal testing and comparison of the key parts; C, establishing a finite element model of complex modal analysis of a brake; D, carrying out model working-condition squeal testing of the brake under a low-temperature working condition; E, carrying out model correction based on testing data of the low-temperature working condition; F, carrying out thermal-mechanical coupling modeling and analysis; G, carrying out boundary condition extraction and analysis; H, carrying out model working-condition squeal testing of the brake under a high-temperatureworking condition; I, carrying out model correction based on testing data of the high-temperature working condition; and J, carrying out different-temperature squeal frequency prediction. Compared with the prior art, the method helps to improve precision of brake squeal prediction, can particularly predict high-frequency noises of the automobile brake under the high-temperature working condition,and can reflect time-varying features of a brake squeal tendency caused by the thermal-mechanical coupling effect.

Owner:TONGJI UNIV

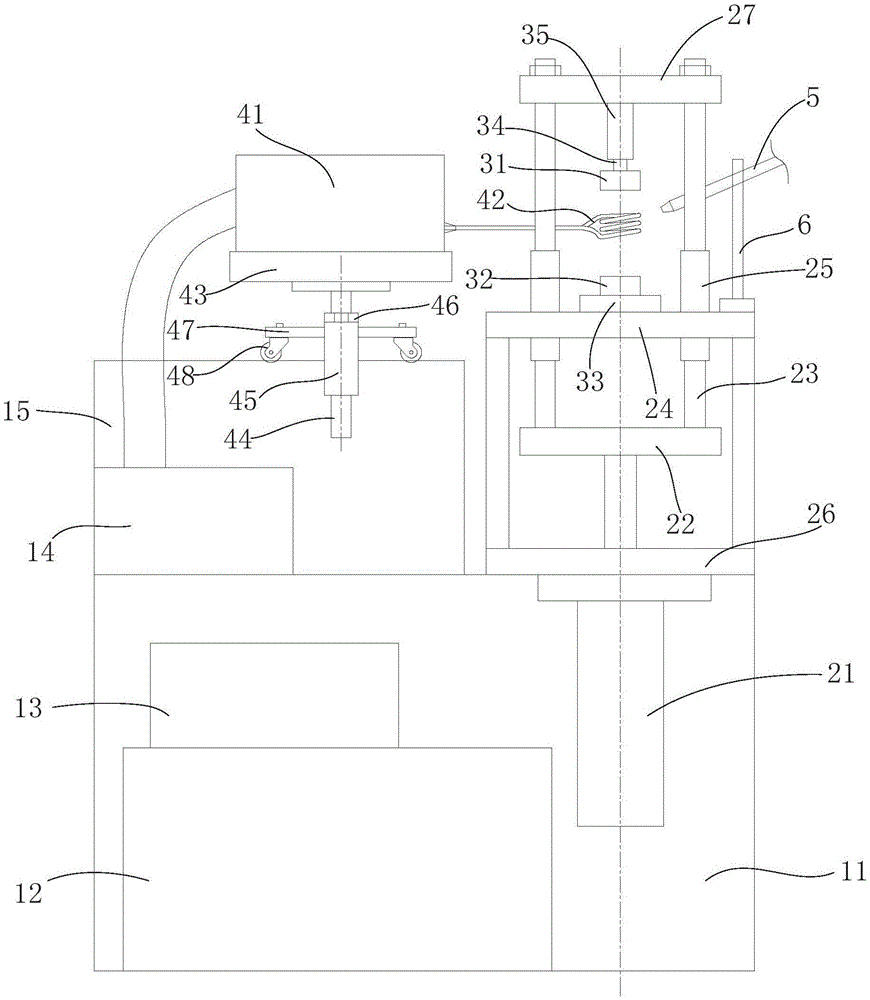

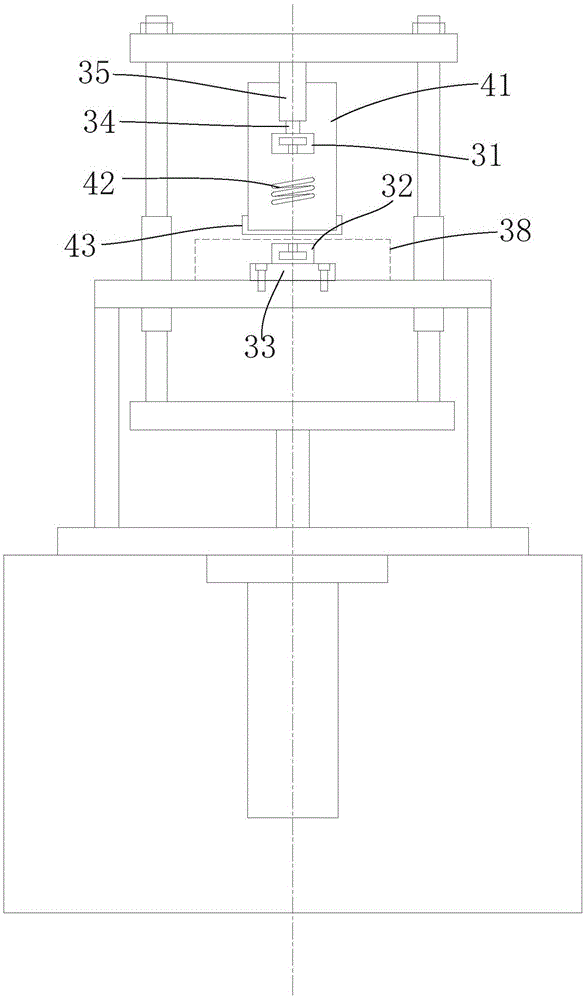

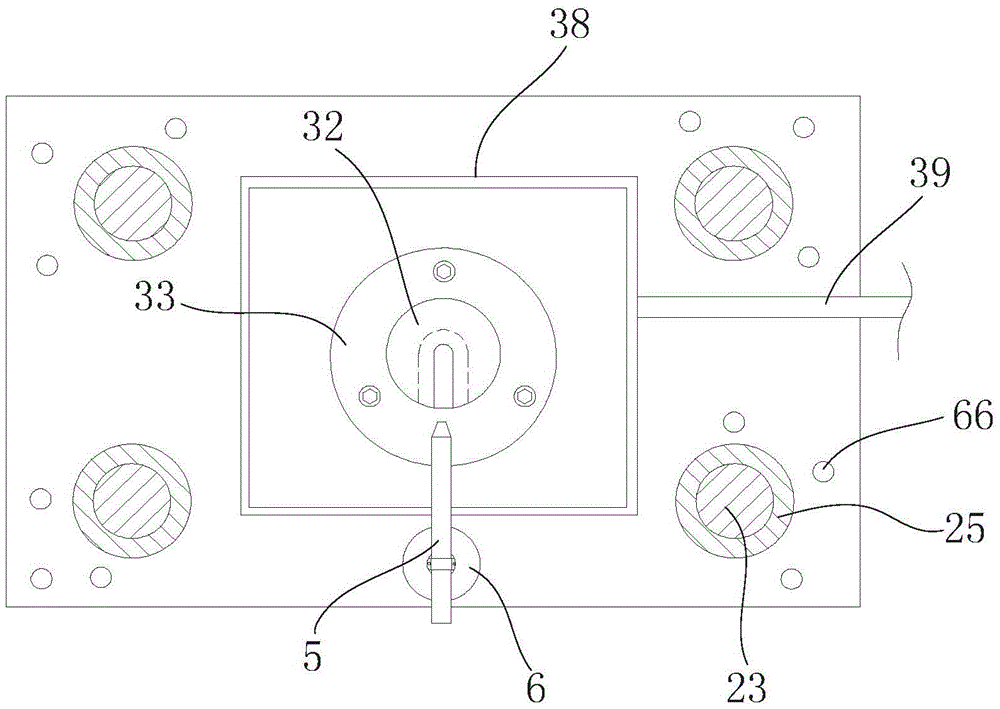

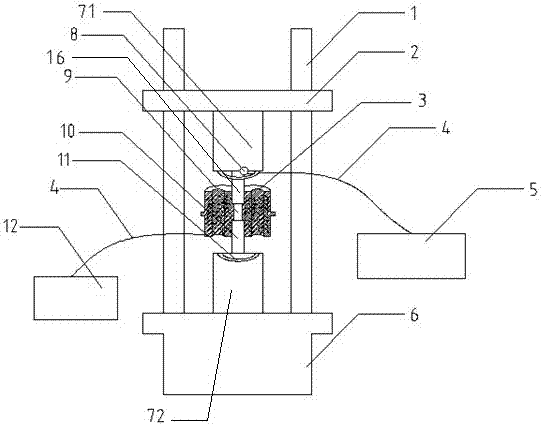

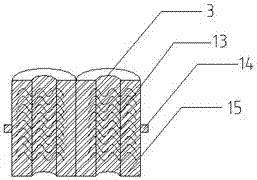

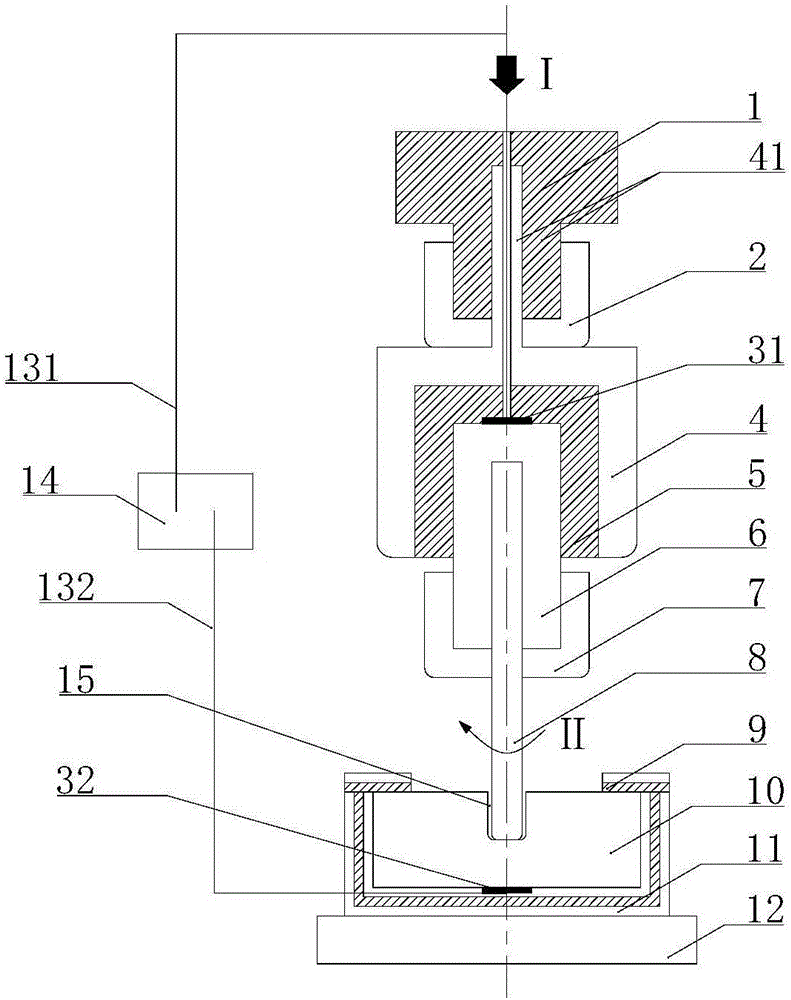

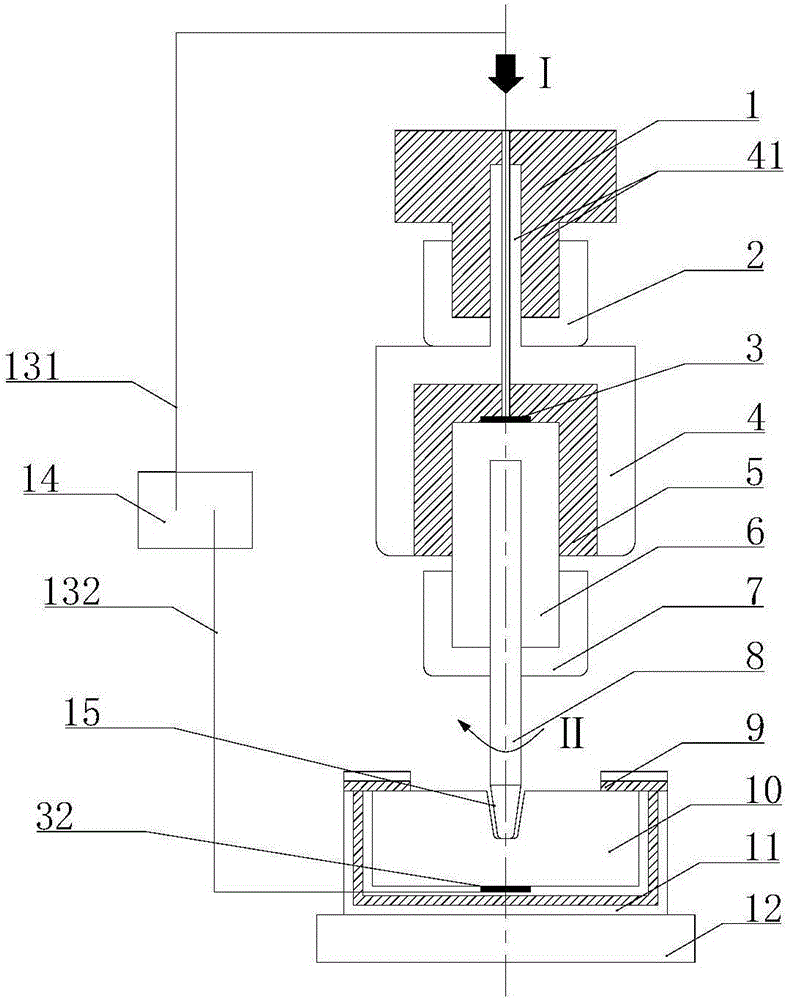

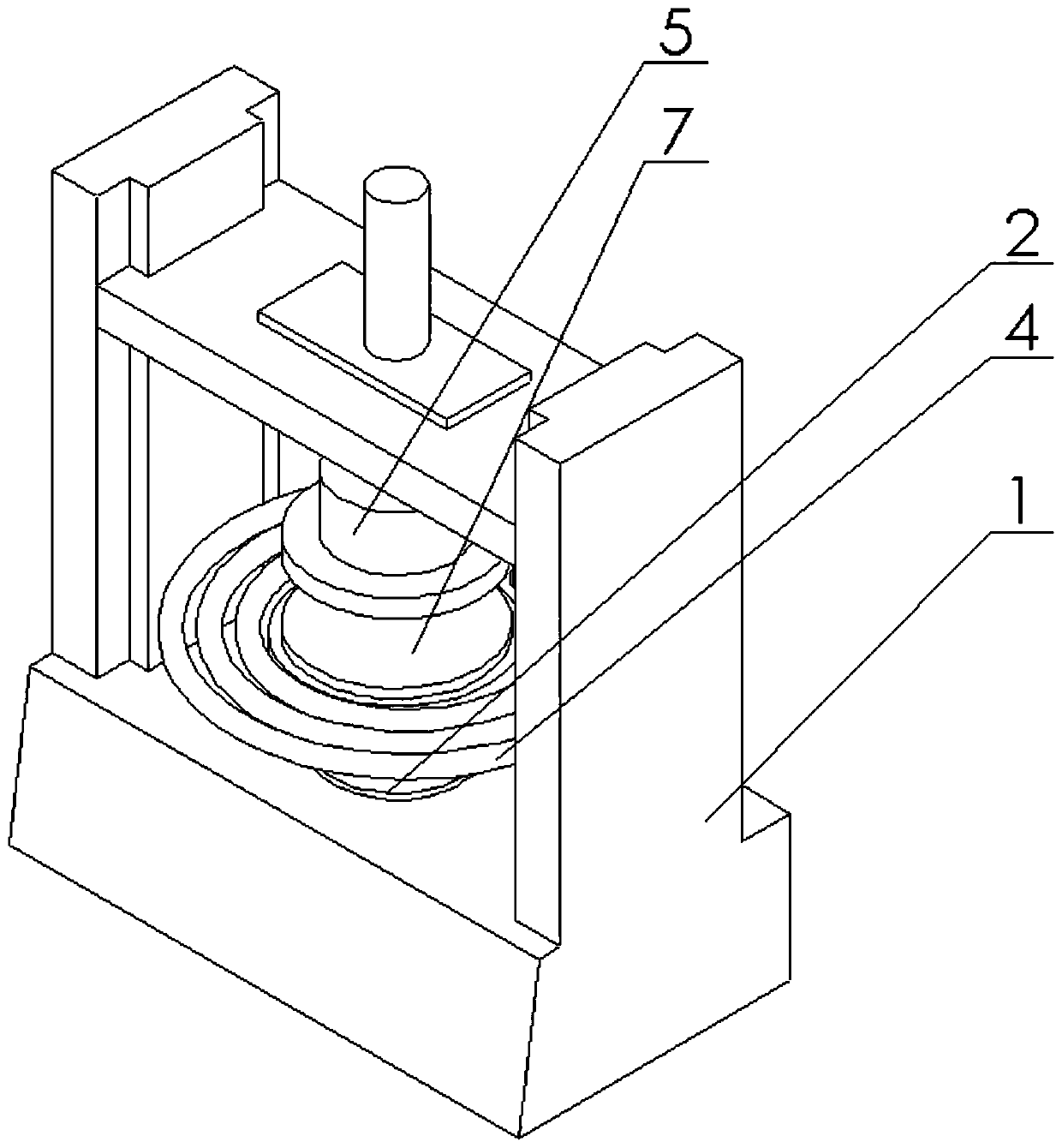

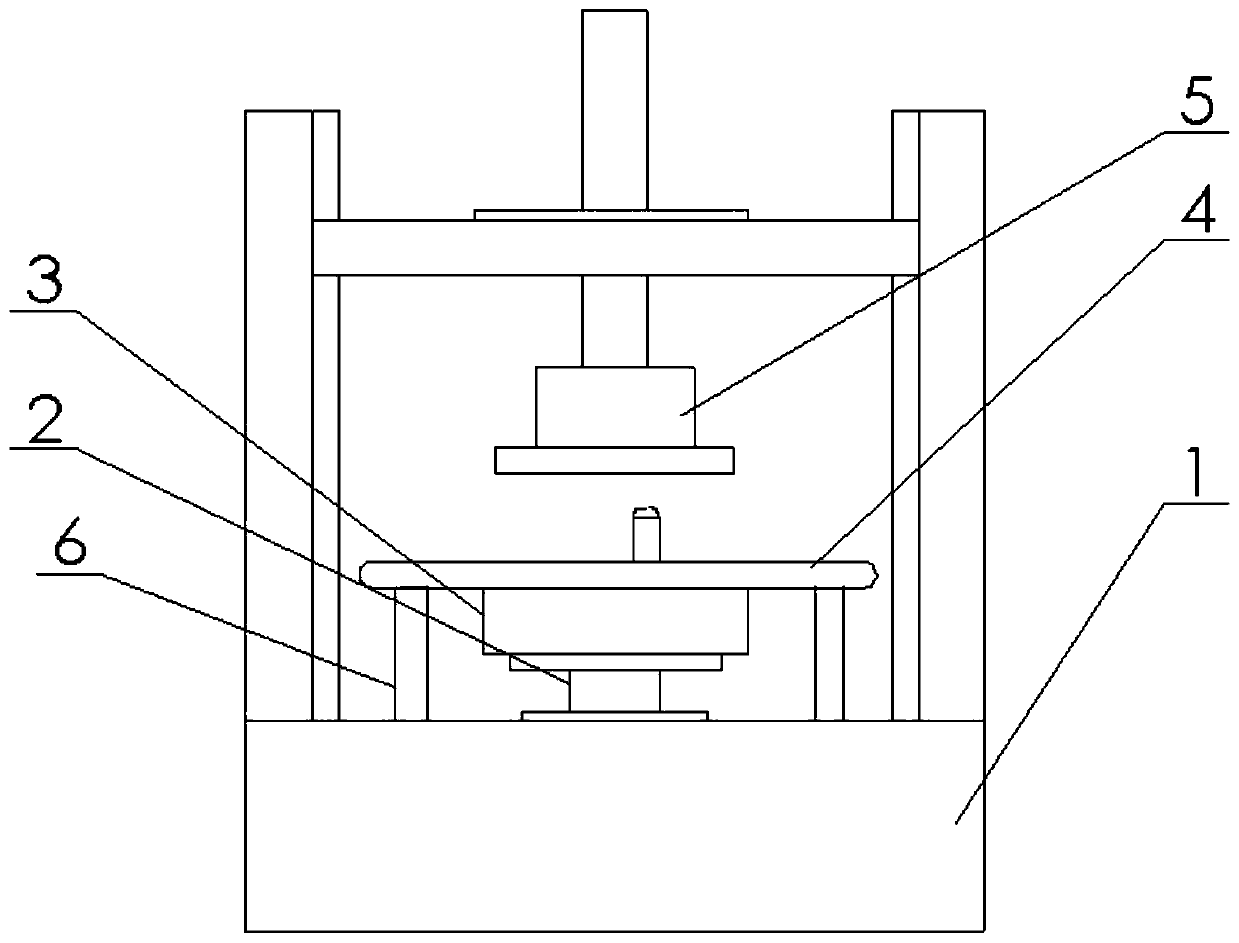

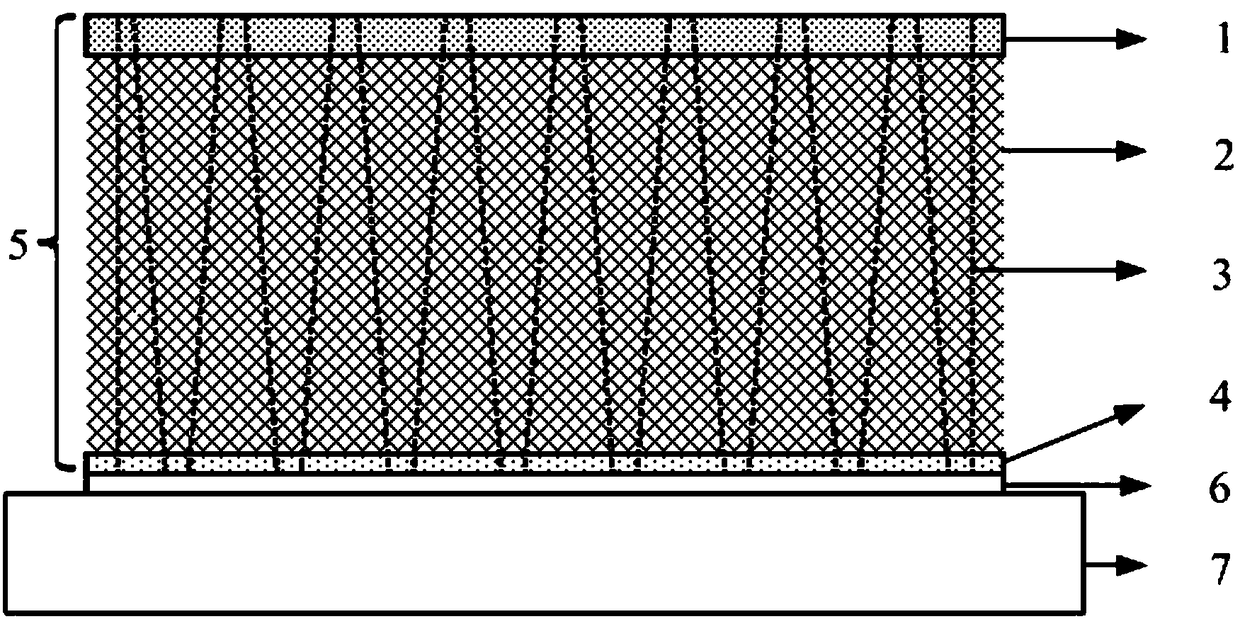

Fatigue testing device of material under thermal-mechanical coupling effect

InactiveCN105651638AAccurate predictionPredict fatigue lifeMaterial strength using tensile/compressive forcesTest efficiencyThermal force

The invention provides a fatigue testing device of a material under a thermal-mechanical coupling effect. The fatigue testing device comprises a loading device used for supplying single-axis tension load or compression load to a sample, an induction heating coil used for quickly heating and a cooling device used for quickly cooling the sample, wherein the loading device comprises two clamp bases and a driving mechanism used for driving the two clamp bases to be close to each other or far from each other; the induction heating coil is located in a sample loading area formed between the two clamp bases; the cooling device is close to the sample loading area and can adopt an air-cooling manner or a water-cooling manner; clamp heads corresponding to the sample are arranged on the two clamp bases; the induction heating coil can rotate horizontally and vertically to adjust the position. The fatigue testing device provides a reasonable test environment for testing the fatigue life of the material or a product under the thermal-mechanical coupling effect, can implement the thermal-mechanical coupling fatigue test under the tension and compression states so as to more accurately predict the fatigue life of the material or the product, and is capable of quickly increasing the temperature, shortening the test period and improving the test efficiency.

Owner:安徽微世特机电设备有限公司

Coal rock three-shaft loading slow pyroelectric detection experiment device and experiment method thereof

InactiveCN103915018AHigh simulationReduce distractionsFuel testingEducational modelsConstant loadElectricity

The invention discloses a coal rock three-shaft loading slow pyroelectric detection experiment device and an experiment method of the coal rock three-shaft loading slow pyroelectric detection experiment device, and belongs to the technical field of coal rock loading charge signal detection. The coal rock three-shaft loading slow pyroelectric detection experiment device and the experiment method of the coal rock three-shaft loading slow pyroelectric detection experiment device can analyze the charge signal variation rules under a coal rock thermal-mechanical coupling effect in a quantitative mode, and have great significance for studying influence on coal rock charge signals from a coal rock slow pyroelectric effect and temperature. The coal rock three-shaft loading slow pyroelectric detection experiment device comprises a coal rock experiment mechanism, a loading system, a heating system, a left charge monitoring system and a right charge monitoring system, wherein the loading system comprises a confining pressure system and an axial pressure system. The experiment method of the coal rock three-shaft loading slow pyroelectric detection experiment device comprises the following steps that firstly, background signals are tested; secondary, the experiment begins, and a coal rock compression fracture charge detection experiment under the condition of a constant temperature or a coal rock slow pyroelectric detection experiment under the condition of a constant load is carried out; thirdly, the coal rock damage mode is observed and recorded.

Owner:LIAONING TECHNICAL UNIVERSITY

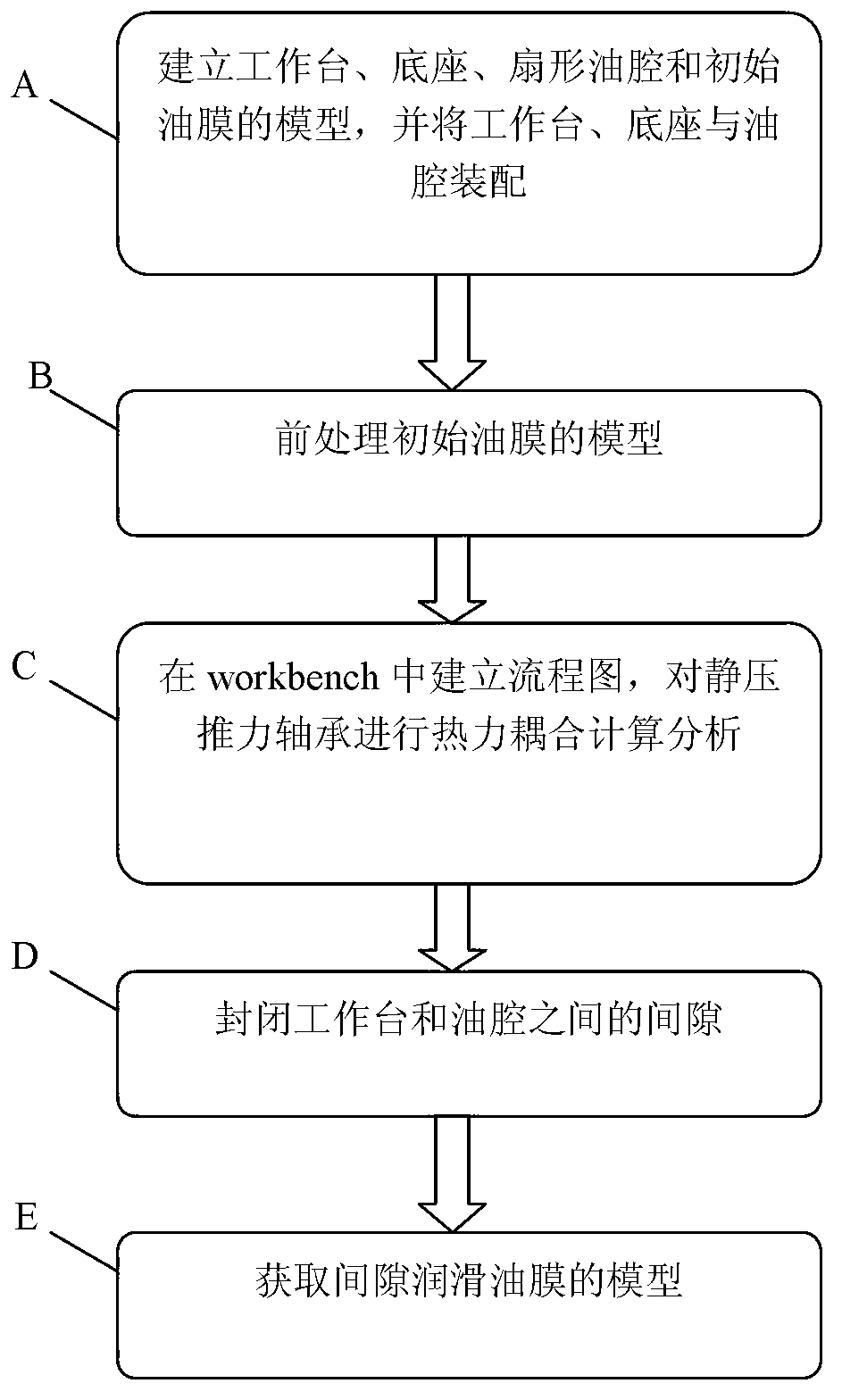

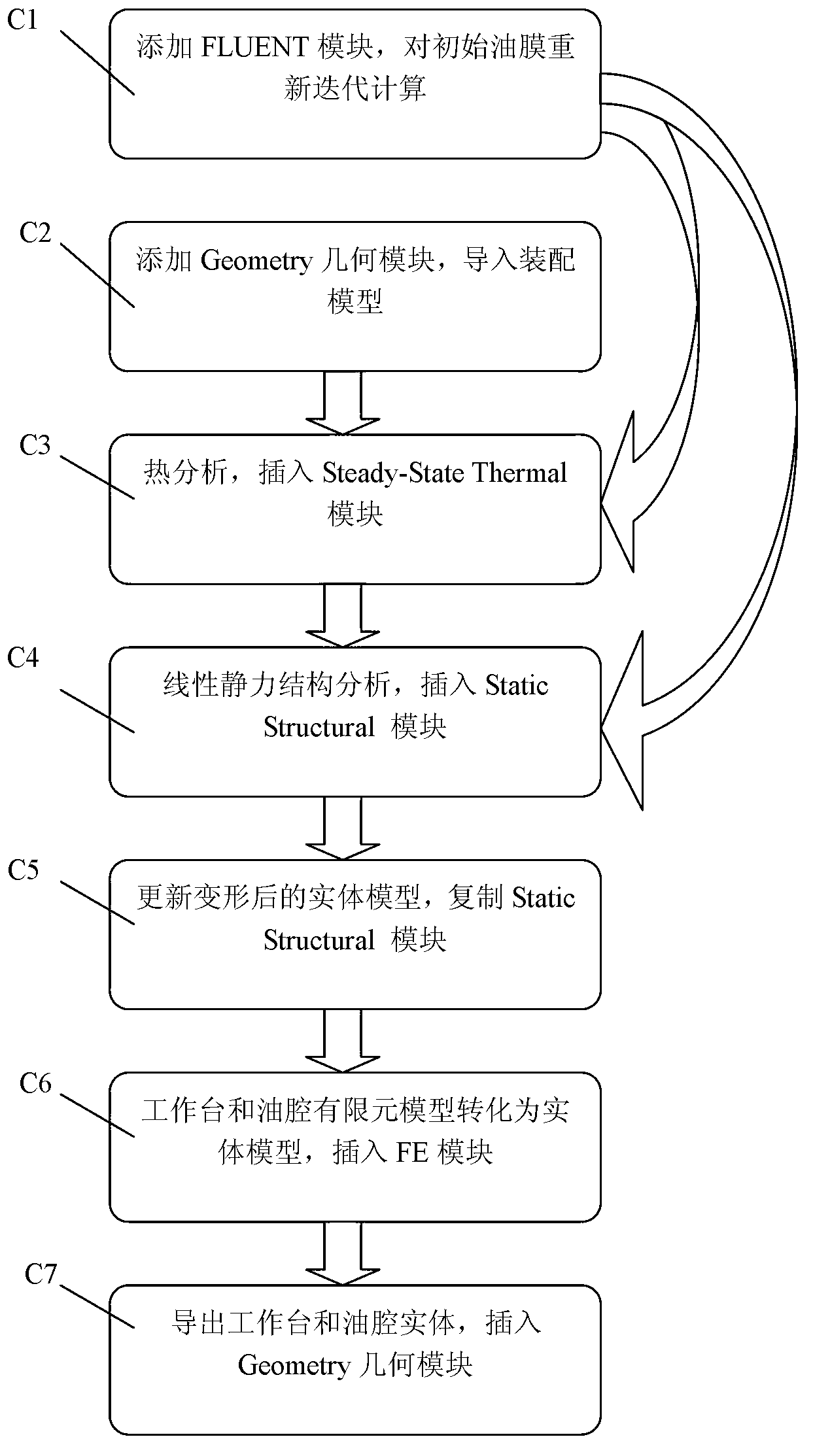

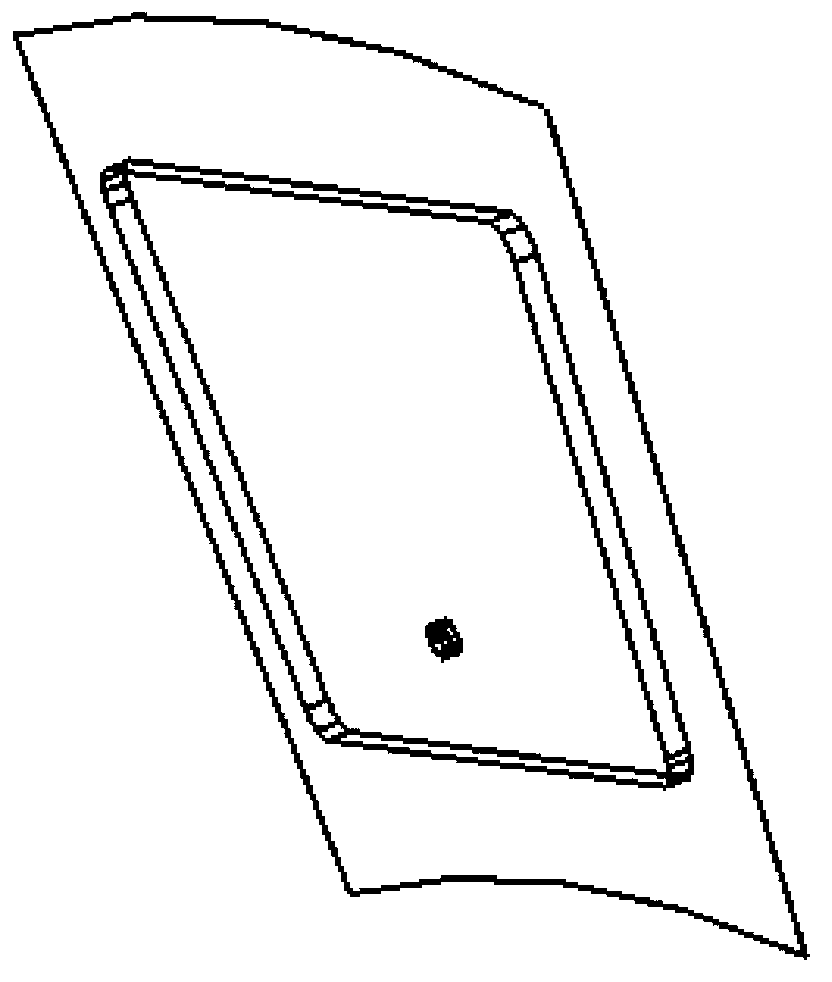

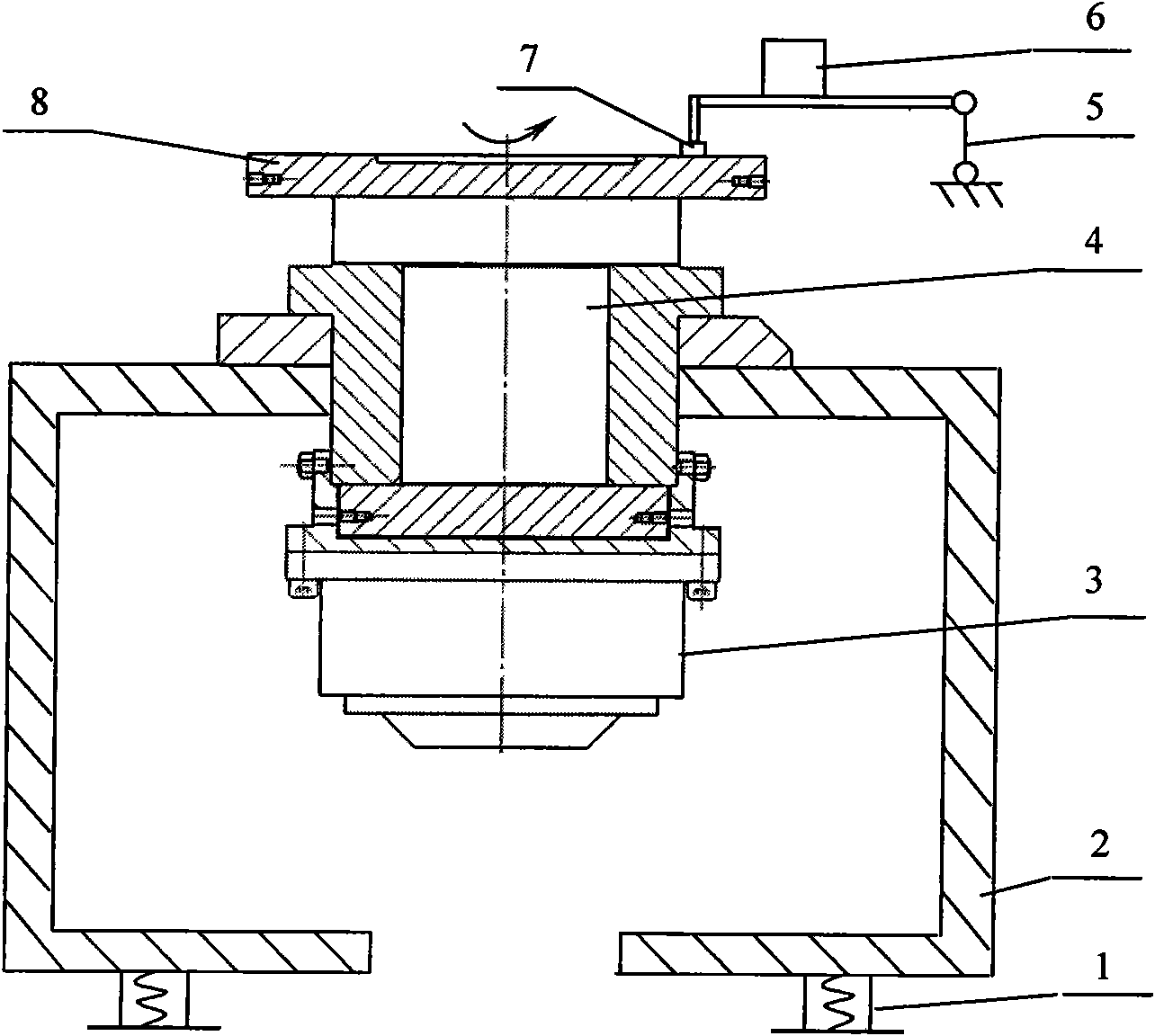

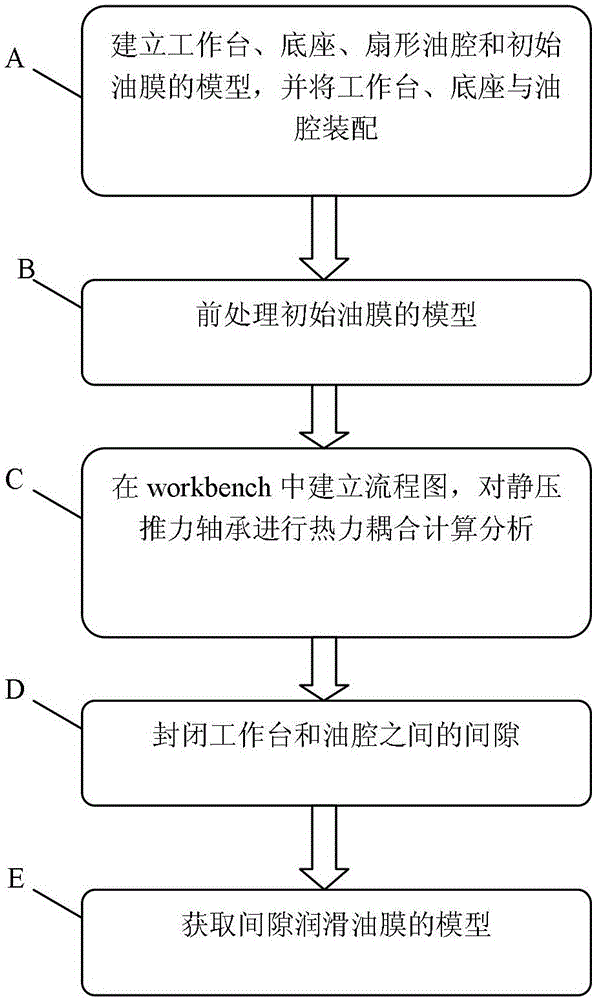

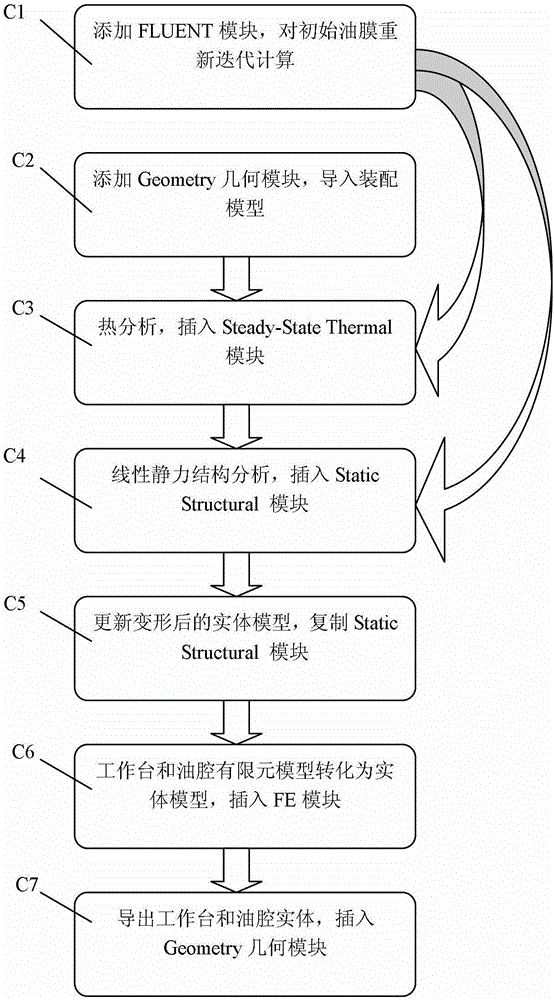

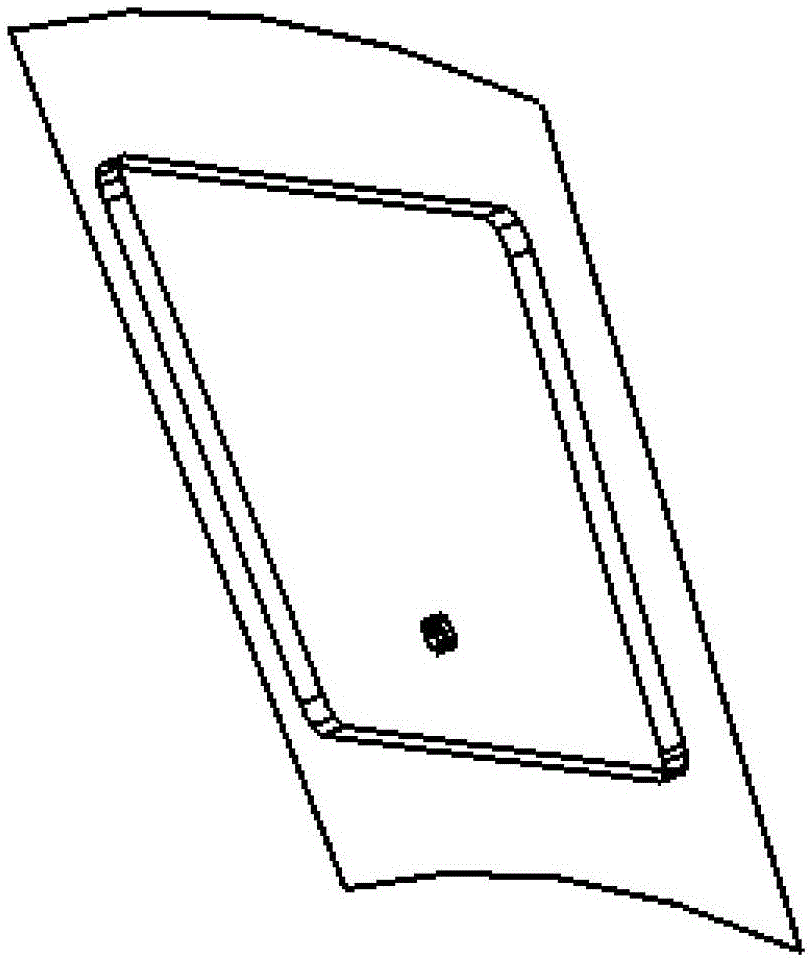

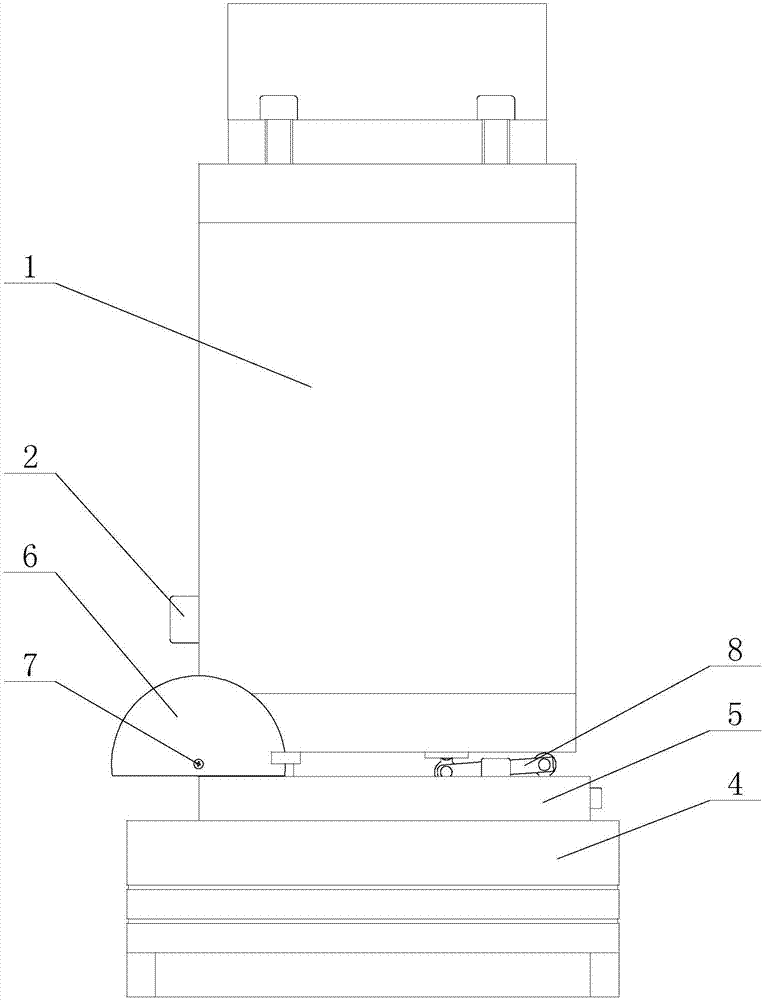

Method for building lubricating oil film model after thermal mechanical coupling deformation of hydrostatic thrust bearing

InactiveCN103246786AAvoid lubrication failureIncrease speedSpecial data processing applicationsThermal mechanical couplingEngineering

The invention provides a method for building a lubricating oil film model after thermal mechanical coupling deformation of a hydrostatic thrust bearing to solve the problem that the efficiency and accuracy of workpieces are largely affected by an existing method for building an oil film model. The method includes the steps: A, building a workbench, a base, a sector oil cavity and a model of an initial oil film and assembling the workbench, the base and the oil cavity; B, pre-treating the model of the initial oil film; C, building a flow chart in the workbench and performing thermal mechanical coupling calculation and analysis for the hydrostatic thrust bearing; D, sealing a gap between the workbench and the oil cavity; and E, obtaining a model of a gap lubricating oil film. The method is applied to the field of lubricating oil film models.

Owner:HARBIN UNIV OF SCI & TECH

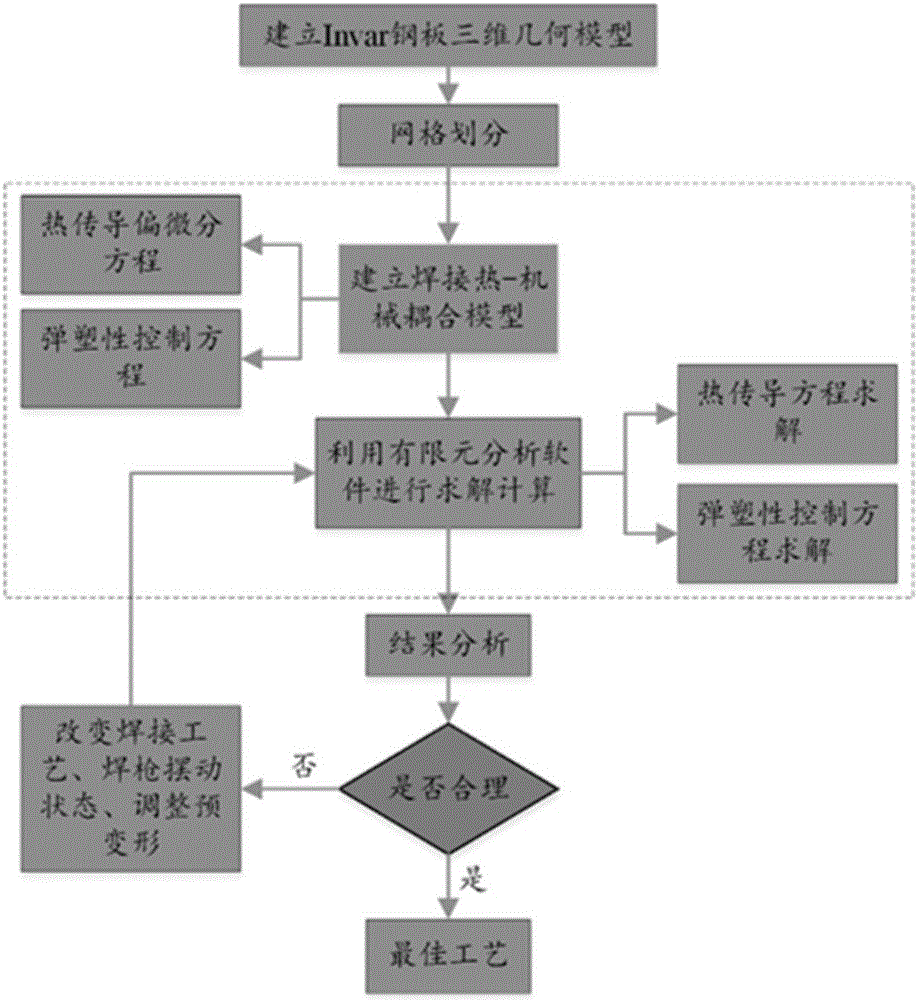

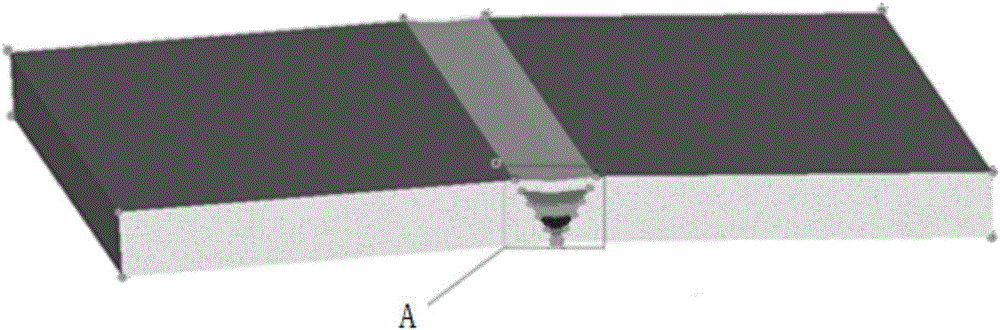

Invar steel PMIG weaving welding temperature field and deformation simulation method

InactiveCN105740577ASimple welding processReduce testing costsGeometric CADSpecial data processing applicationsPre deformationThick plate

The invention discloses an Invar steel PMIG weaving welding temperature field and a deformation simulation method.A thermal-mechanical coupling model used for analyzing an Invar steel thick plate temperature field and a stress strain field; through reasonably setting welding technology parameters, a swinging route and pre-deformation, the established coupling model is solved and calculated by the utilization of related finite element analysis software, the Invar steel temperature field and strain field distribution and deformation conditions under the corresponding welding technology parameters are obtained through loading and solving thermal boundary conditions and mechanical boundary conditions, and then the welding technology is instructed and optimized.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

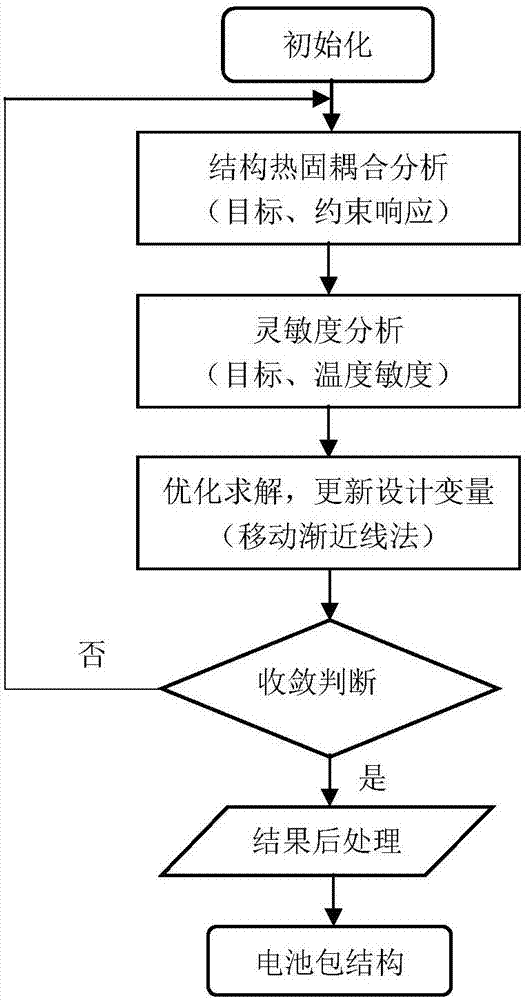

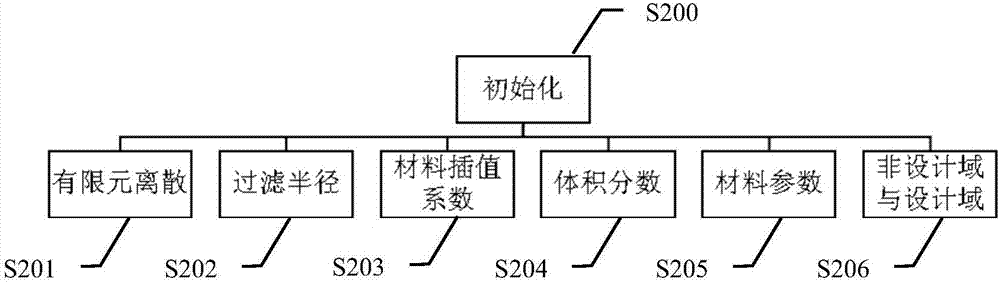

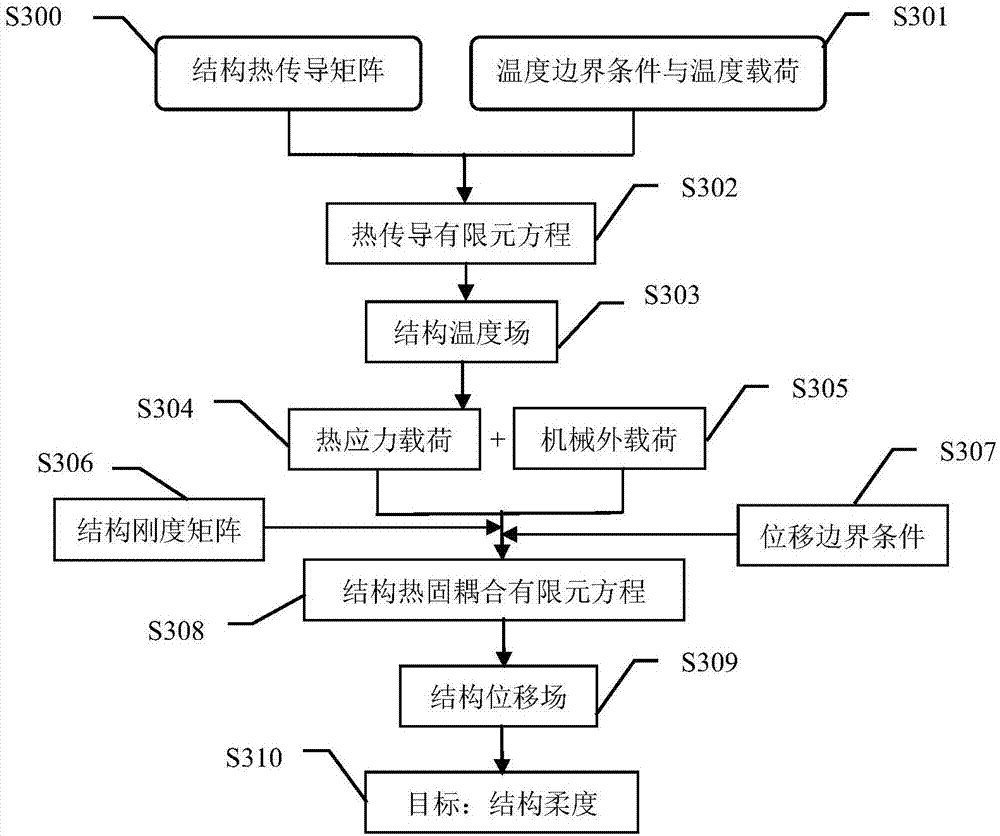

Metal heat dissipation power battery pack structural design method and battery pack

ActiveCN107887669AFree from excessive deformationSimple structureSecondary cellsCell component detailsTopology optimizationField analysis

Disclosed are a metal heat dissipation power battery pack structural design method and a battery pack. The design method comprises the steps of performing material, boundary and load defining, performing non-design region and design region defining, carrying out finite element discrete, solving a structural total heat conduction matrix and total rigidity array, performing structural thermosettingcoupling field analysis, performing structural flexibility and temperature sensitivity analysis, performing flexibility sensitivity analysis, carrying out grid filtering to eliminate a checkboard format, introducing volume constraint and temperature constraint, developing the temperature constraint and performing thermal-mechanical coupling topology optimization, and performing battery pack planarstructure optimization and the like. The battery pack has high and uniform heat dissipation performance and relatively high rigidity, and furthermore, the continuation of the journey and driving safety of an electric vehicle are improved.

Owner:DALIAN UNIV OF TECH

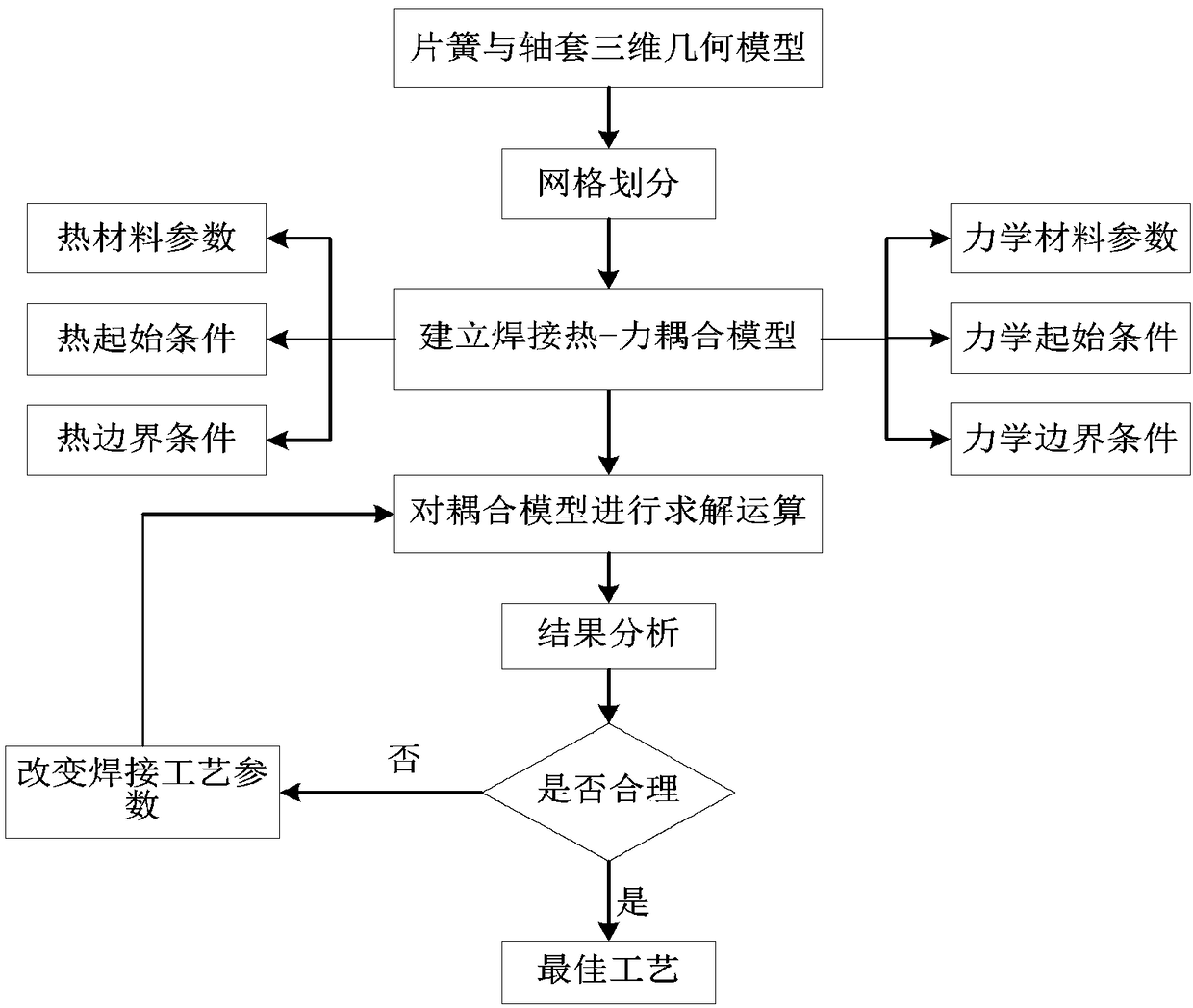

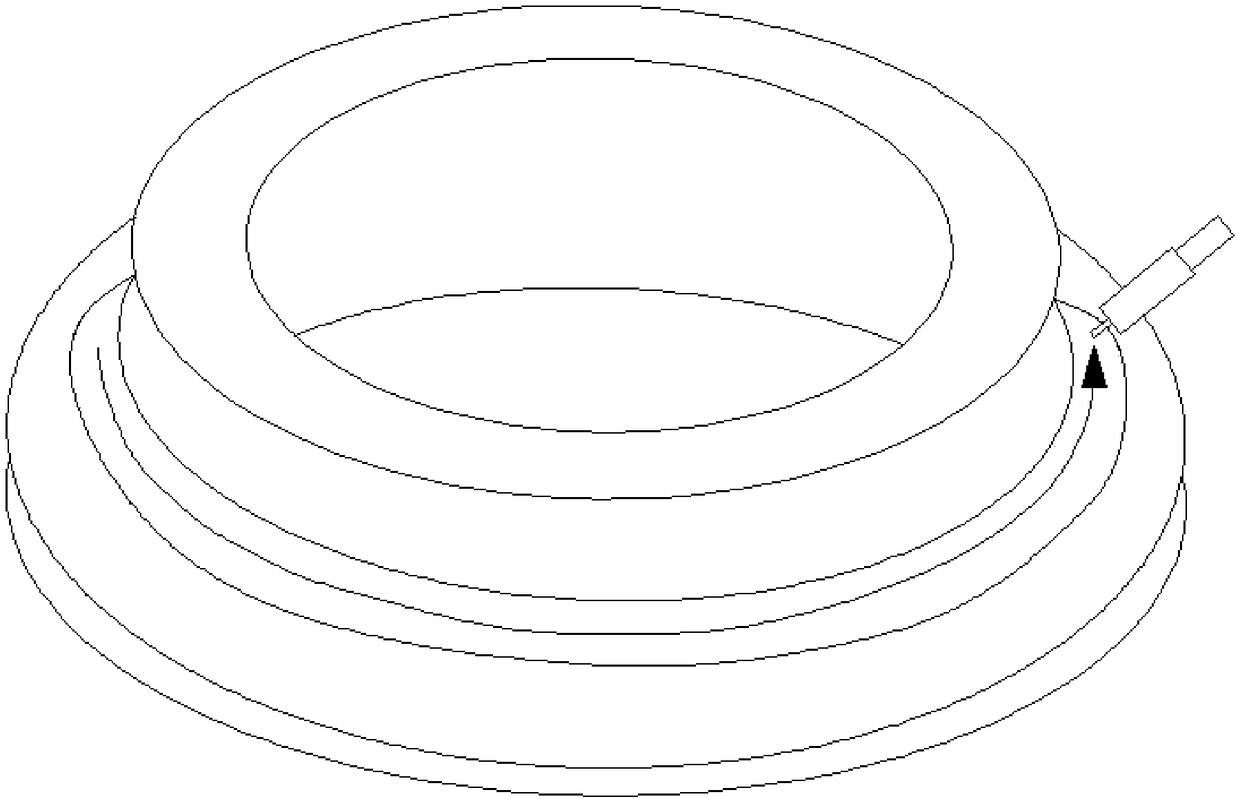

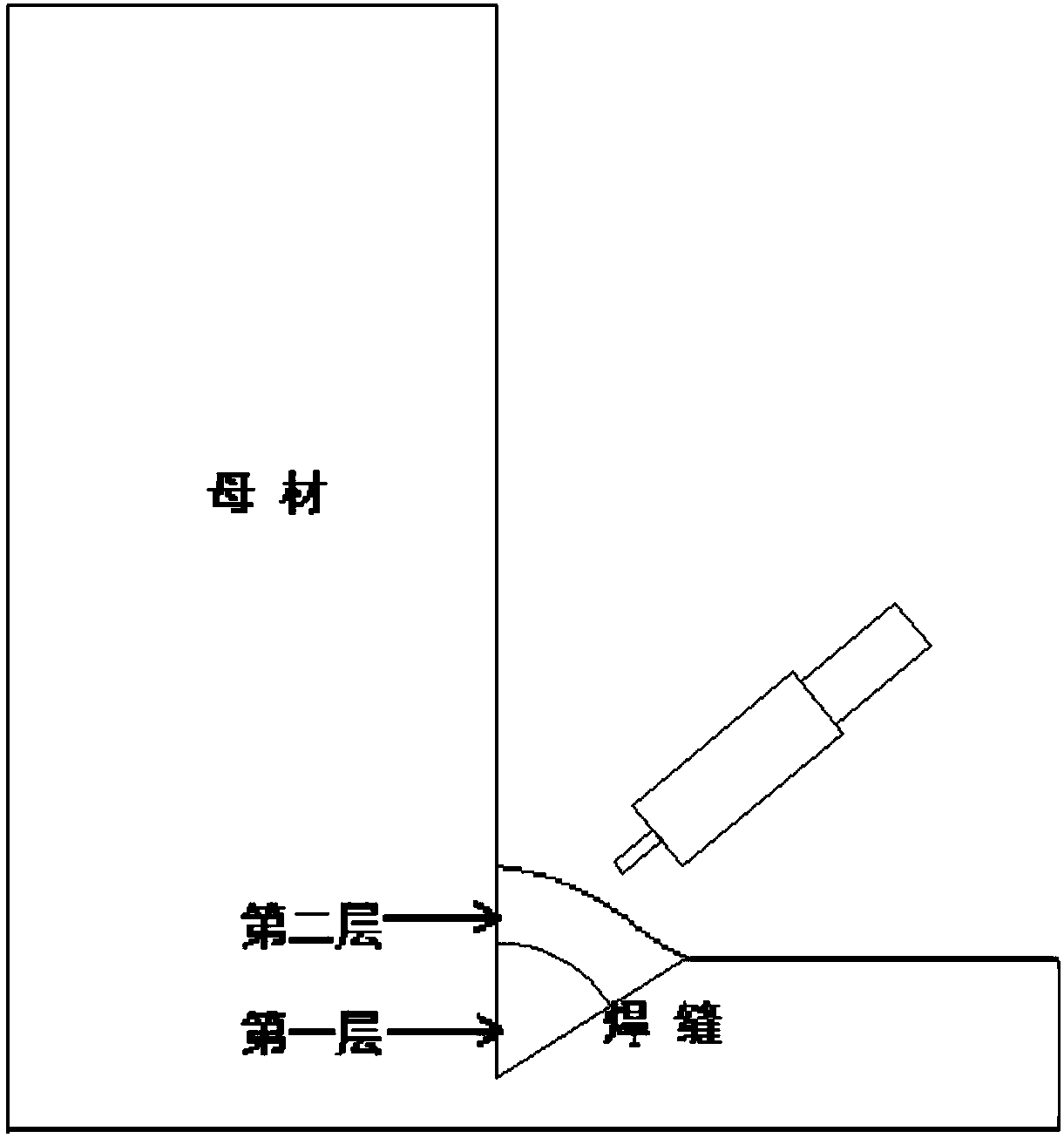

Accurate deformation control-oriented multilayer and multi-pass welding technology for hollow stabilizer bars of automobiles

InactiveCN108334663AQuality improvementRealize simulationGeometric CADDesign optimisation/simulationWelding residual stressEngineering

The invention discloses an accurate deformation control-oriented multilayer and multi-pass welding technology for hollow stabilizer bars of automobiles. The accurate deformation control-oriented multilayer and multi-pass welding technology includes steps of 1), building three-dimensional geometric models matched with the hollow stabilizer bars of the automobiles; 2), carrying out grid division onthe three-dimensional geometric models; 3), building coupling models of temperature fields and stress and strain fields in multilayer and multi-pass welding procedures for the hollow stabilizer bars of the automobiles; 4), setting thermal-mechanical material parameters, multilayer and multi-pass welding heat sources and multilayer and multi-pass welding paths for the hollow stabilizer bars of theautomobiles, loading initial conditions and boundary conditions according to actual welding situations, solving and computing the thermal-mechanical coupling models by the aid of numerical simulationmethods and analyzing and judging obtained results. The accurate deformation control-oriented multilayer and multi-pass welding technology for the hollow stabilizer bars of the automobiles has the advantages that the three-dimensional coupling models are built, welding technologies are optimized by the aid of modeling by finite element methods and emulation research, accordingly, technological exploration workload can be reduced, and the optimal technologies with functions of controlling welding residual stress and welding deformation ca be obtained.

Owner:YANGZHOU DONGSHENG AUTOMOBILE PARTS LTD BY SHARE LTD

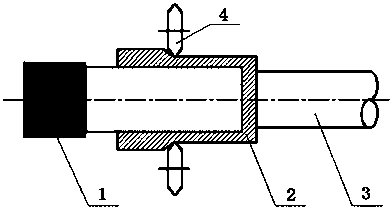

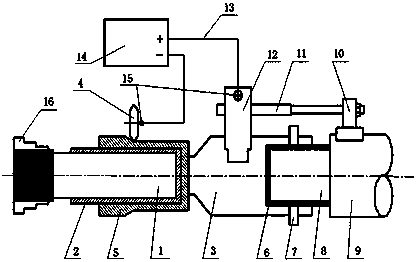

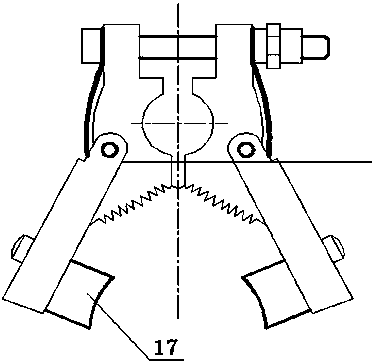

Self-incremental spinning thermal mechanical coupling synchronous forming device and method for titanium-containing laminated composite tube

ActiveCN108246902AHigh bonding strengthNo crackingShaping toolsOther manufacturing equipments/toolsInterference fitLow voltage

The invention provides a self-incremental spinning thermal mechanical coupling synchronous forming device and method for a titanium-containing laminated composite tube. The self-incremental spinning thermal mechanical coupling synchronous forming device comprises a titanium tube blank, a titanium tube blank fixing device, a machining tool group, a self-resistance heating tool and a spinning forming device. The self-resistance heating tool comprises a high-frequency low-voltage power supply, a carbon brush holder assembly, a carbon brush rod, a magnetic fixing frame and a wire, wherein one endof the carbon brush rod is in interference fit with the carbon brush holder assembly through insulating treatment, and the other end of the carbon brush rod is fixed to the magnetic fixing frame in ascrew thread fit mode. The magnetic fixing frame is fixed to a moving tip. The positive pole of the high-frequency low-voltage power supply is connected with the carbon brush holder assembly through the wire, and the negative pole of the high-frequency low-voltage power supply is connected with a binding post of a spinning wheel. The high-frequency low-voltage power supply, the titanium tube blank, the spinning wheel, a tail top, the wire and the carbon brush holder assembly constitute a current loop. According to the self-incremental spinning thermal mechanical coupling synchronous forming device and method for the titanium-containing laminated composite tube, the prepared titanium-containing laminated composite tube is subjected to thermal mechanical coupling spinning, the bonding strength between the inner and outer pipe interfaces is large, and no cracking occurs.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

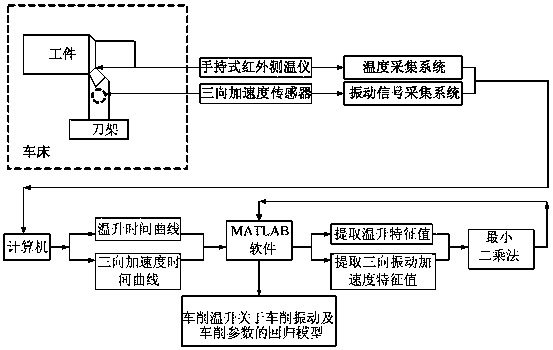

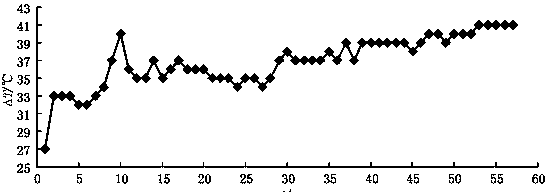

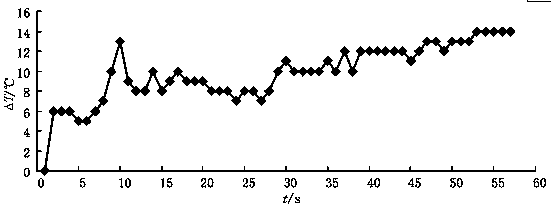

Prediction method for turning temperature rise mean value of tool

ActiveCN107066775AEasy to set upThe prediction method is simple and applicableSpecial data processing applicationsInformaticsVibration accelerationPredictive methods

The invention discloses a prediction method for a turning temperature rise mean value of a tool. A signal collected by a signal collection system is processed to obtain a three-direction acceleration mean value and a temperature rise mean value in each turning test; a multiple regression model, about turning three-direction vibration acceleration and turning parameters, of the temperature rise mean value of the tool is obtained based on a least square method; and the model is used for predicting the temperature rise mean value of the tool under different turning parameters and different turning vibrations. According to the method, the turning temperature rise is predicted by integrating the turning vibrations and the turning parameters, and turning heat is analyzed by adopting the temperature rise value (relative temperature), so that the influence of difference of different environment temperatures on the turning heat can be eliminated; and a necessary constitutive equation can be provided for theoretical and numerical analog calculation of a thermal mechanical coupling characteristic of the turning, and the difficulty in real-time measurement of the turning temperature can be relieved to a certain extent.

Owner:XUZHOU NORMAL UNIVERSITY

Thermal-mechanical coupling edge grinding technology applicable to manufacturing diamond tools

InactiveCN101659020AImprove efficiencySimple sharpening processOther manufacturing equipments/toolsDynamic balanceEngineering

The invention relates to a thermal-mechanical coupling edge grinding technology applicable to manufacturing diamond tools. The thermal-mechanical coupling edge grinding technology can solve the problem that the existing mechanical edge grinding technology of the diamond tools can not lead the sharpness of cutting edges of the diamond tools to be better than 10nm. The method comprises the followingsteps of: regulating an edge grinding machine tool of the diamond tools to be balanced; carrying out thermal treatment after carrying out fine-turning forming on a working surface of a steel grindingdisc, and carrying out fine polishing to achieve the mirror effect; carrying out fine dynamic balancing on a main shaft system of the grinding machine tool; clamping the diamond tool and regulating aclamp of a tool body to be horizontal; opening a gas source, turning on a power supply of the edge grinding machine tool of the diamond tools and regulating the revolution speed of a main shaft of the machine tool; adjusting the edge grinding direction of a front tool face to be easy to grind and regulating a front angle of the tool; and carrying out edge grinding on the tool under the conditionsthat the grinding speed is 33.96m / s, the grinding pressure is 5.95N and the grinding time is 5min. The technology is characterized by simple edge grinding technology, low cost and high efficiency andcan prepare the diamond tools with the sharpness of the cutting edges of being better than 10nm by edge grinding.

Owner:HARBIN INST OF TECH

High-temperature and high-pressure hydrofracturing clamp holder and test method thereof

PendingCN109870349AImprove test success rateEasy to operateMaterial strength using tensile/compressive forcesEngineeringHigh pressure

The invention discloses a high-temperature and high-pressure hydrofracturing clamp holder and a test method thereof. The high-temperature and high-pressure hydrofracturing clamp holder comprises a test barrel, a barrel upper mounting part, a barrel lower mounting part and a barrel inner mounting part. A hydrofracturing test can be carried out for a small rock sample; a single test can be carried out by one person; the operation is convenient; the test success rate is high; and the single test cost is relatively low. The clamp holder has five seal designs in total, so that test failure caused by liquid leakage in a test process can be effectively avoided; seal parts are sealed in a related part compressing mode, and in a heating process or the test process, the seal parts can be continuously compressed; and a seal pre-tightening force application and provision part is specially designed in the barrel inner mounting part, so that expansion force after heating of the part in the test process can be resisted, research on a fracture mechanical behavior of a high-temperature and high-pressure rock mass under a thermal-mechanical coupling effect is facilitated, and theoretical basis and guidance can be provided for construction engineering of reservoir layers in high-temperature rock mass geothermal exploitation engineering.

Owner:CHINA UNIV OF MINING & TECH

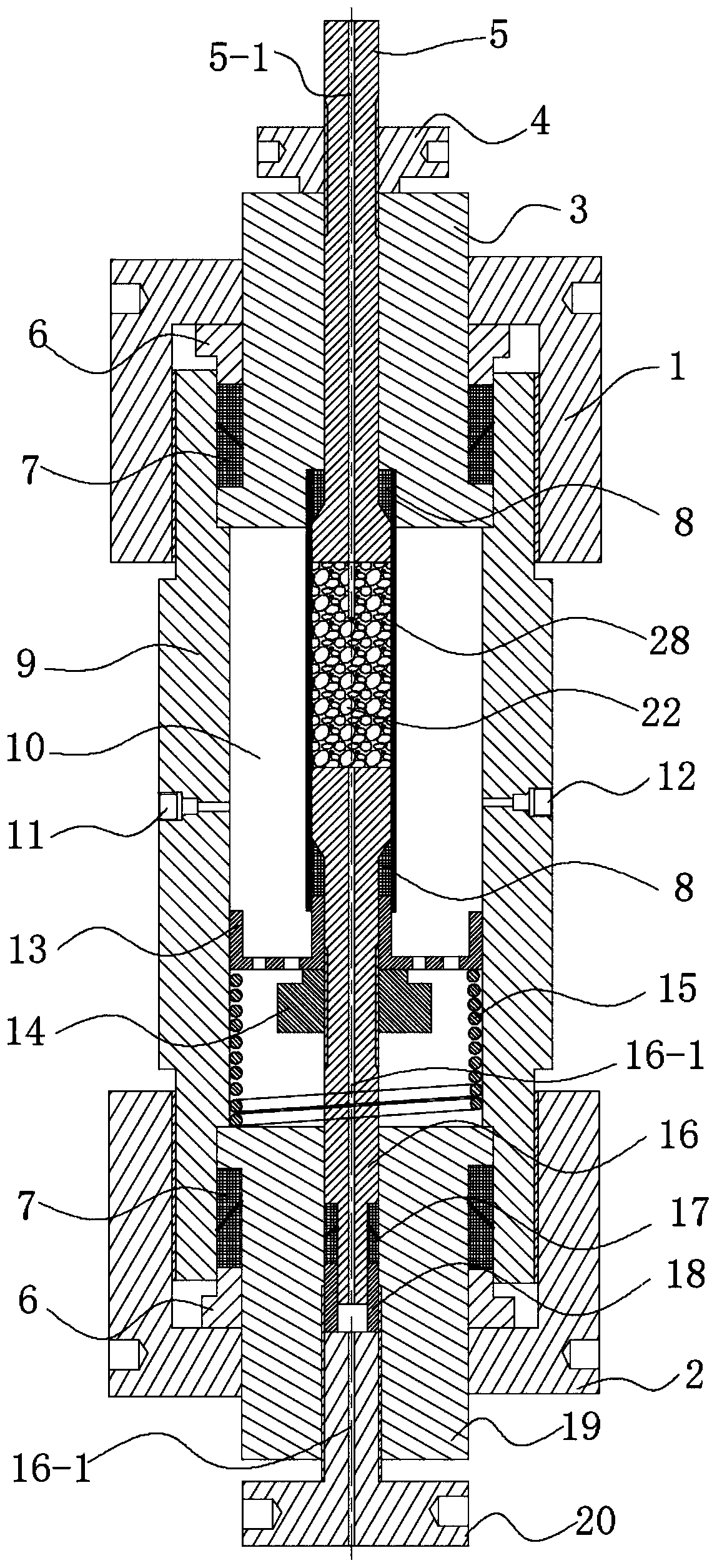

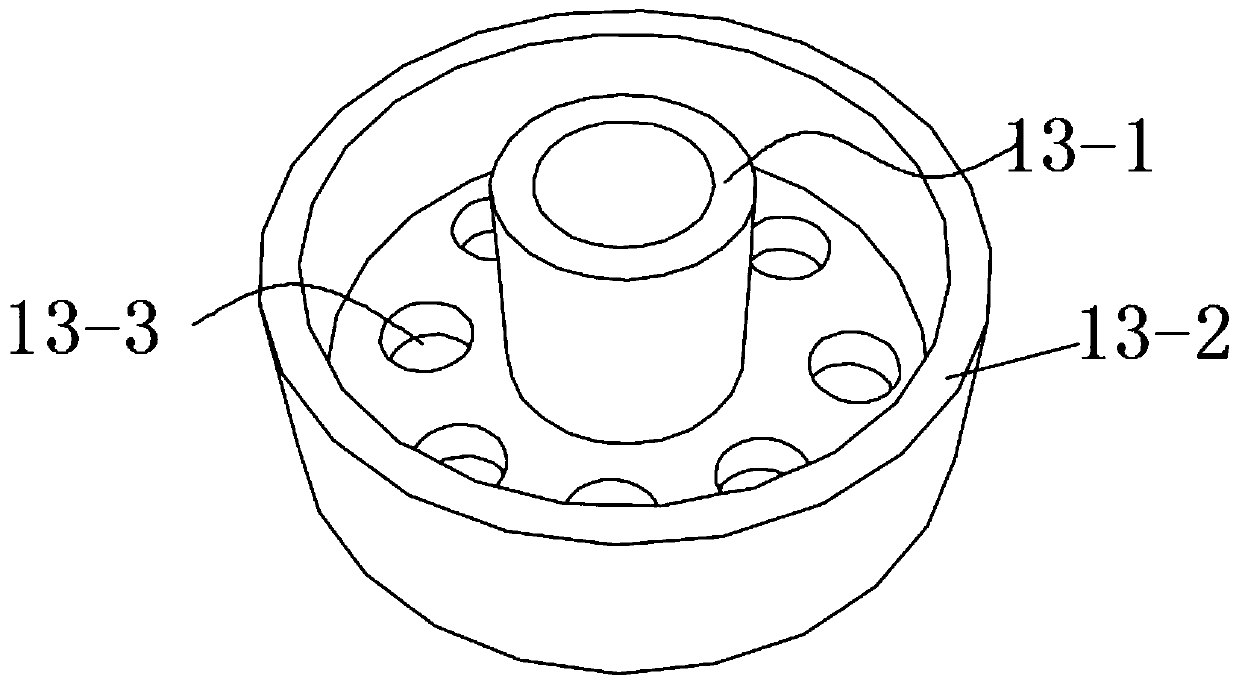

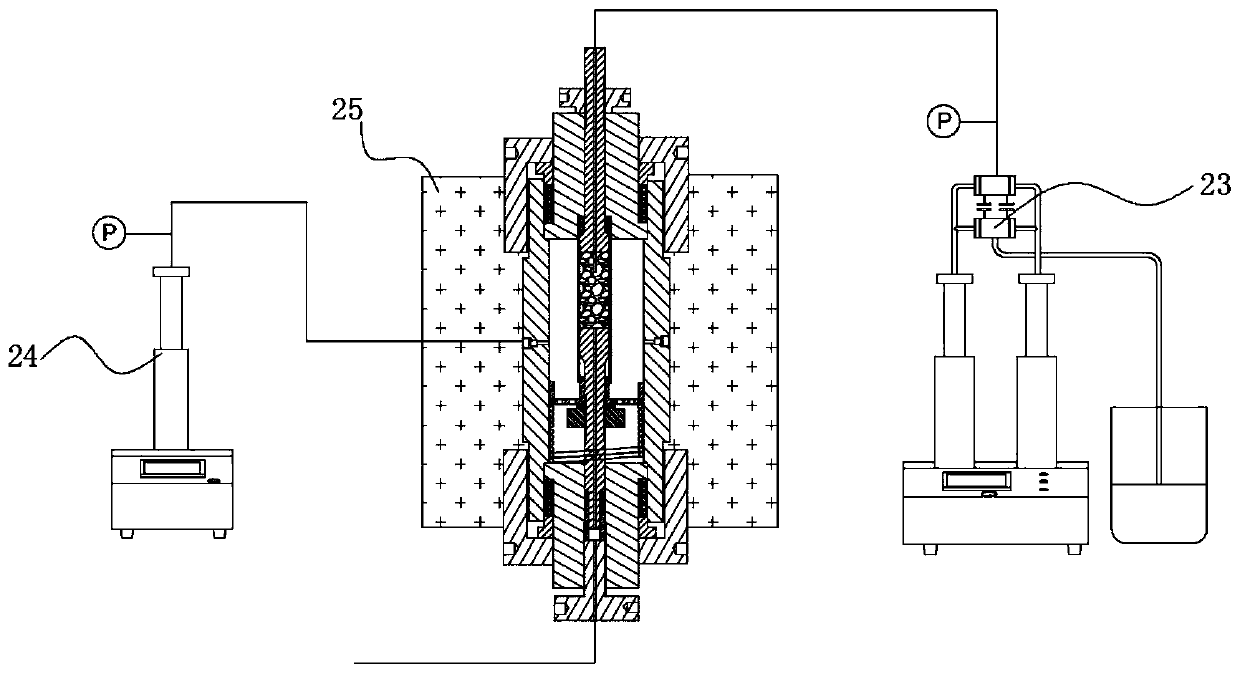

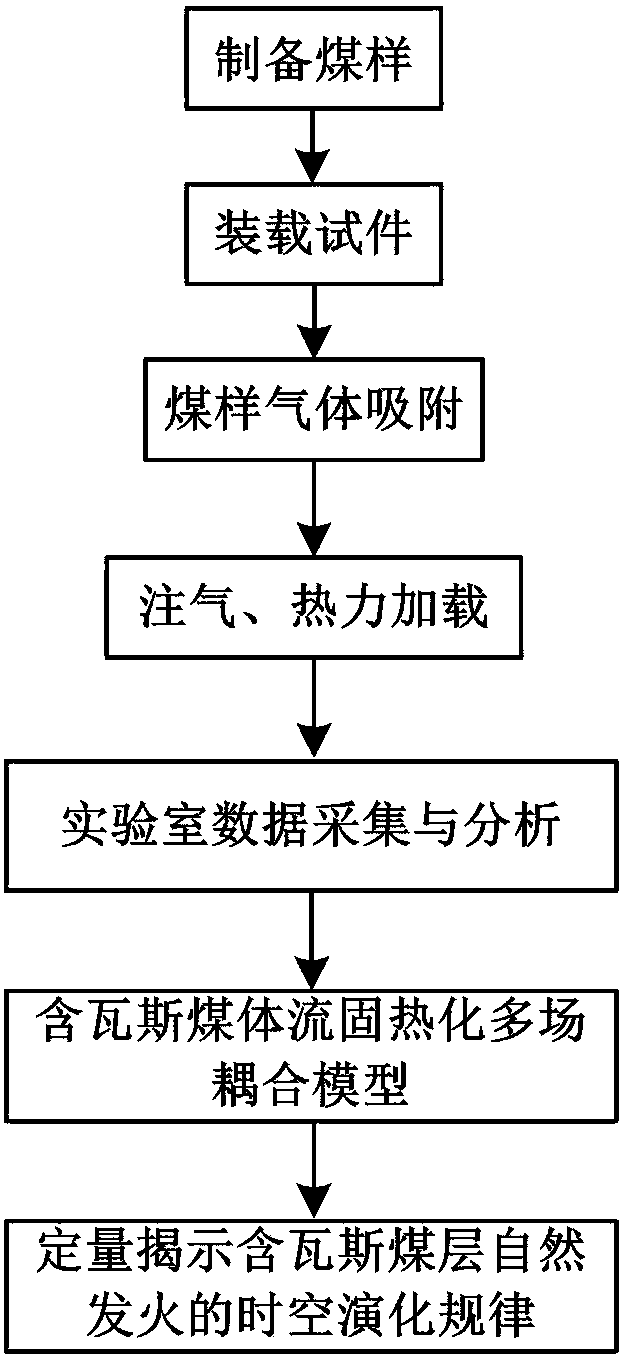

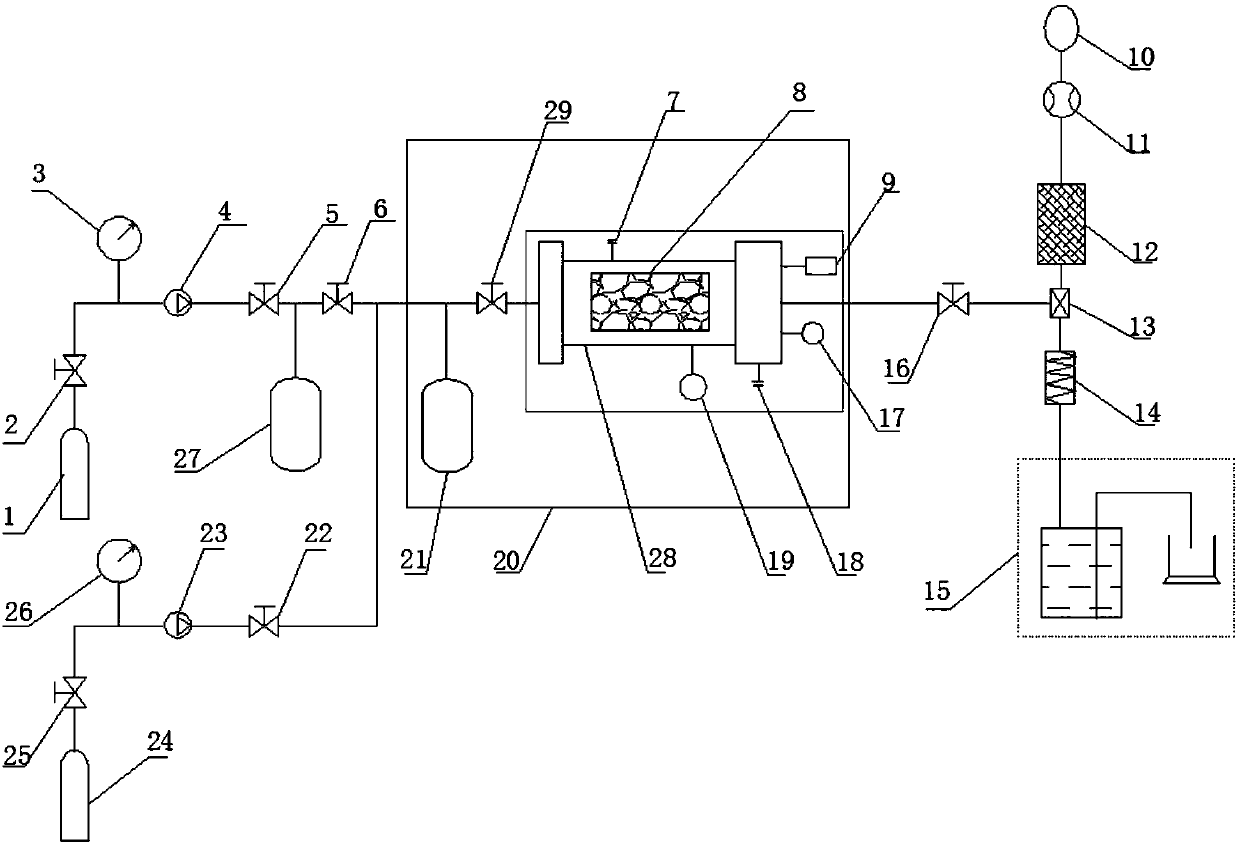

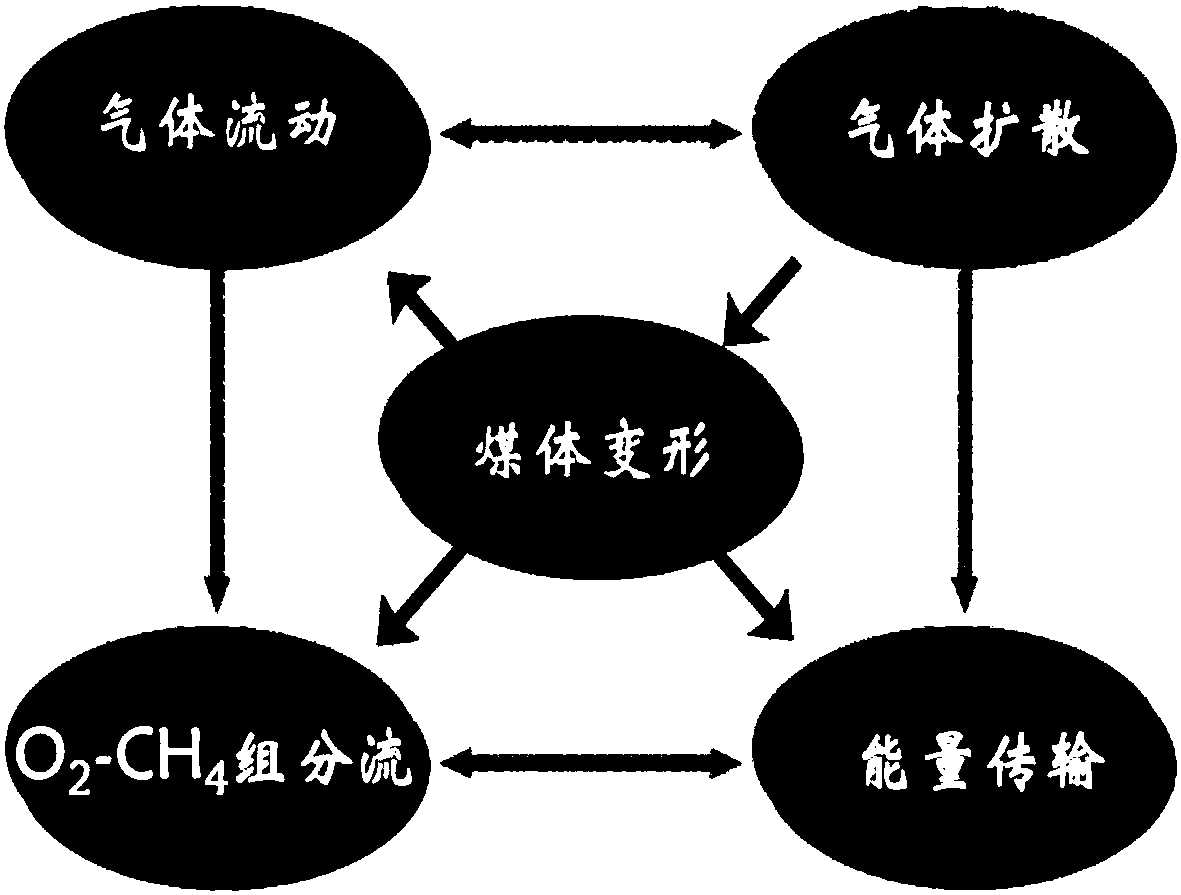

Experimental method for simulating coal mass fluid-solid thermal-chemical multi-field coupling under thermal-mechanical coupling

ActiveCN107064450AReal record of fluid-solid-thermal-chemical multi-process couplingSolve the problem that the oxidation cycle is usually as long as several months, and it is even difficult to observe the oxidation phenomenonFuel testingReaction ruleSpontaneous combustion

The invention discloses an experimental method for simulating coal mass fluid-solid thermal-chemical multi-field coupling under thermal-mechanical coupling, which comprises the following steps: preparing a coal sample; loading a test sample, and performing gas adsorption of a coal sample; setting an initial confinement pressure, an initial temperature and an initial axial stress of a molded coal test sample and the loading thresholds for the temperature and the axial stress; injecting oxygen gas, and heating the molded coal test sample; performing first time of data collection; carrying out temperature and stress combined loading; performing second time of data collection; establishing a coal mass seepage-stress-temperature-chemical multi-field coupling model, and studying and revealing coal mass fluid-solid thermal-chemical coupling mechanism under thermal-mechanical coupling in combination with a numerical simulation method. The experimental method disclosed by the invention realizes laboratory simulation of the spontaneous combustion temperature rise rule under coal seam stress loading, can be used for quantitative study of the coal mass stress-strain relationship, coal mass permeability evolution and coal-oxygen reaction rule under thermal-mechanical coupling, and provides basis for predicting coal seam spontaneous combustion sites and time and determining the best time for controlling spontaneous combustion.

Owner:CHINA UNIV OF MINING & TECH

Testing method for testing building structural materials under thermal-mechanical coupling effect

InactiveCN107389468APerformance benefits researchResearch high temperature resistanceMaterial strength using tensile/compressive forcesSystem testingMaterials testing

The invention discloses a testing method for testing building structural materials under a thermal-mechanical coupling effect. The method comprises the following steps: constituting a thermal-mechanical coupling system by utilizing a servo loading device, high-temperature equipment and an acoustic emission testing system, putting a test piece into upper and lower overhanging arms, regulating the servo system to perform preset loading on the test piece, performing real-time temperature rise on the test piece according to an international temperature rising curve ISO 834 by utilizing the high-temperature equipment, starting the acoustic emission testing system to monitor the test piece in the whole process so as to simulate the current situation that the building structural materials are stressed by a certain load when a fire happens, performing pressure-bearing test on the test piece when a target temperature reaches, and testing the mechanical properties of the test piece under the thermal-mechanical coupling effect, such as thermal expansion deformation, stress, strain, residual bearing capacity, elasticity modulus and the like by virtue of the servo system, thereby researching the performances of the building structural materials under the thermal-mechanical coupling effect.

Owner:YANGZHOU UNIV

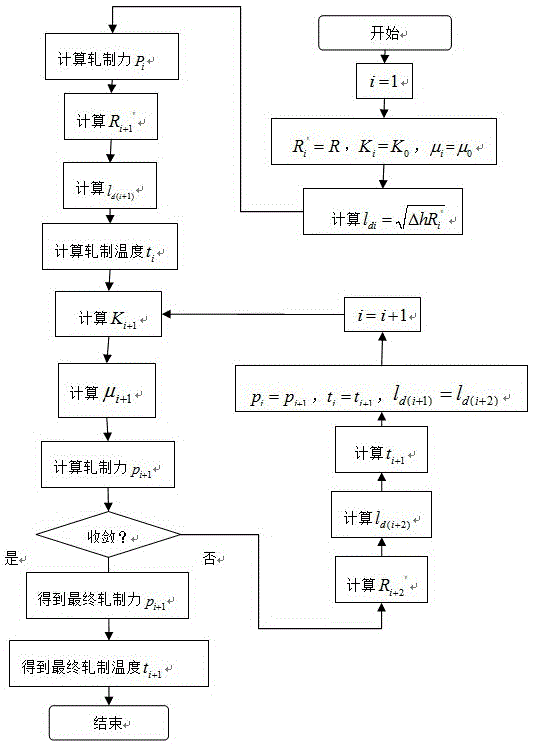

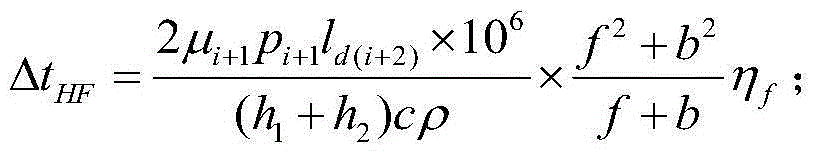

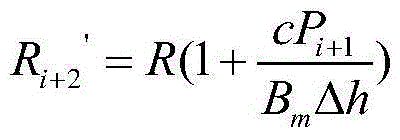

Rolling force and rolling temperature mutual iteration calculating method

ActiveCN105022923AImprove technical effectImprove forecast accuracySpecial data processing applicationsWhole bodyCalculation methods

The present invention relates to a rolling force and rolling temperature mutual iteration calculating method. After a rolling force is primarily calculated, corresponding roll flattening radius and rolling temperature are calculated according to the rolling force; according to the rolling temperature obtained by calculation, deformation resistance and a friction coefficient are calculated so as to fulfill the aim of calculating the rolling force according to the rolling temperature; then the sequentially calculated rolling forces are compared to be determined whether to be equal; if the sequentially calculated rolling forces are different a little, i.e. the convergence condition is reached, iteration is completed; and the rolling force and the rolling temperature which are obtained by final calculation are used as calculation results. If the convergence condition is not reached, the roll flattening radius and the rolling temperature are calculated again according to the calculated rolling force, then the rolling force is calculated again according to the rolling temperature, and the convergence condition is rejudged whether to be reached. According to the present invention, the facts that the rolling force and the rolling temperature are mutually influenced in the actual production process and thermal mechanical coupling exists are considered; and by a numerical iteration method, the calculating processes of the rolling force and the rolling temperature are used as one whole body and the objective condition of mutual influence of the rolling force and the rolling temperature is reduced so as to simultaneously improve prediction accuracy of rolling force and rolling temperature models.

Owner:HUNAN CITY UNIV

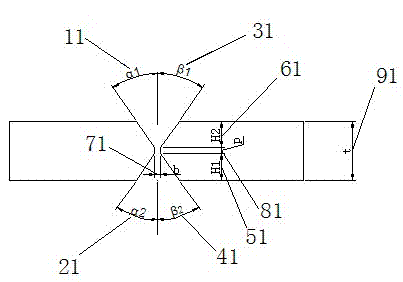

Electric current assisted friction column/tapered plug welding method and tool thereof

InactiveCN106181021AReduce processing requirementsReduced Power RequirementsNon-electric welding apparatusElectrical resistance and conductancePower flow

The invention discloses an electric current assisted friction column / tapered plug welding method which comprises the following steps: according to the technological requirements of friction plug welding, a cylindrical or frustum-shaped stopper rod is adopted to prefabricate a taphole in the to-be-welded area of a workpiece; a tool is utilized to clamp the stopper rod and the workpiece, and the taphole and the stopper rod are enabled to be coaxial; a welding machine and an auxiliary power supply are started, axial force is applied while rotating the stopper rod to form a conductive loop among the auxiliary power supply, the stopper rod, the workpiece and a conductive block, the end material of the stopper rod rapidly reaches the thermoplasticity state under the action of friction heat and resistance heat, and at the same time, a plastic material moves around to fill an interval under the action of thermal mechanical coupling, and the interval is filled as the welding process is carried out; and after upsetting is finished, the welding machine and the auxiliary power supply are turned off, so that electric current assisted friction column / tapered plug welding is finished. With adoption of the electric current assisted friction column / tapered plug welding method, requirements for friction heat can be lowered, so that requirements for the power system of welding equipment are lowered, plug weld texture and mechanical properties can be improved, and a welding process window can be widened.

Owner:TIANJIN UNIV

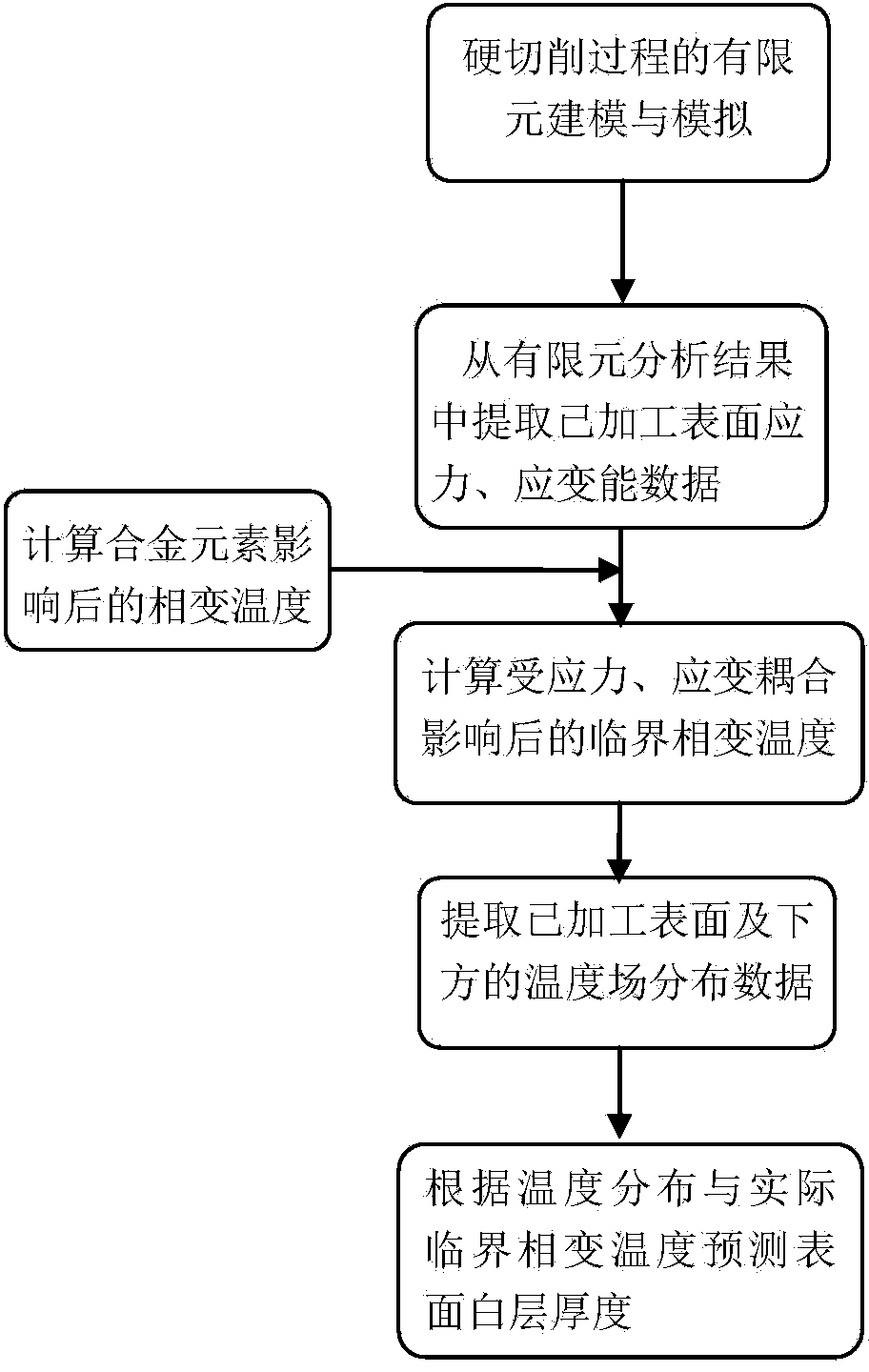

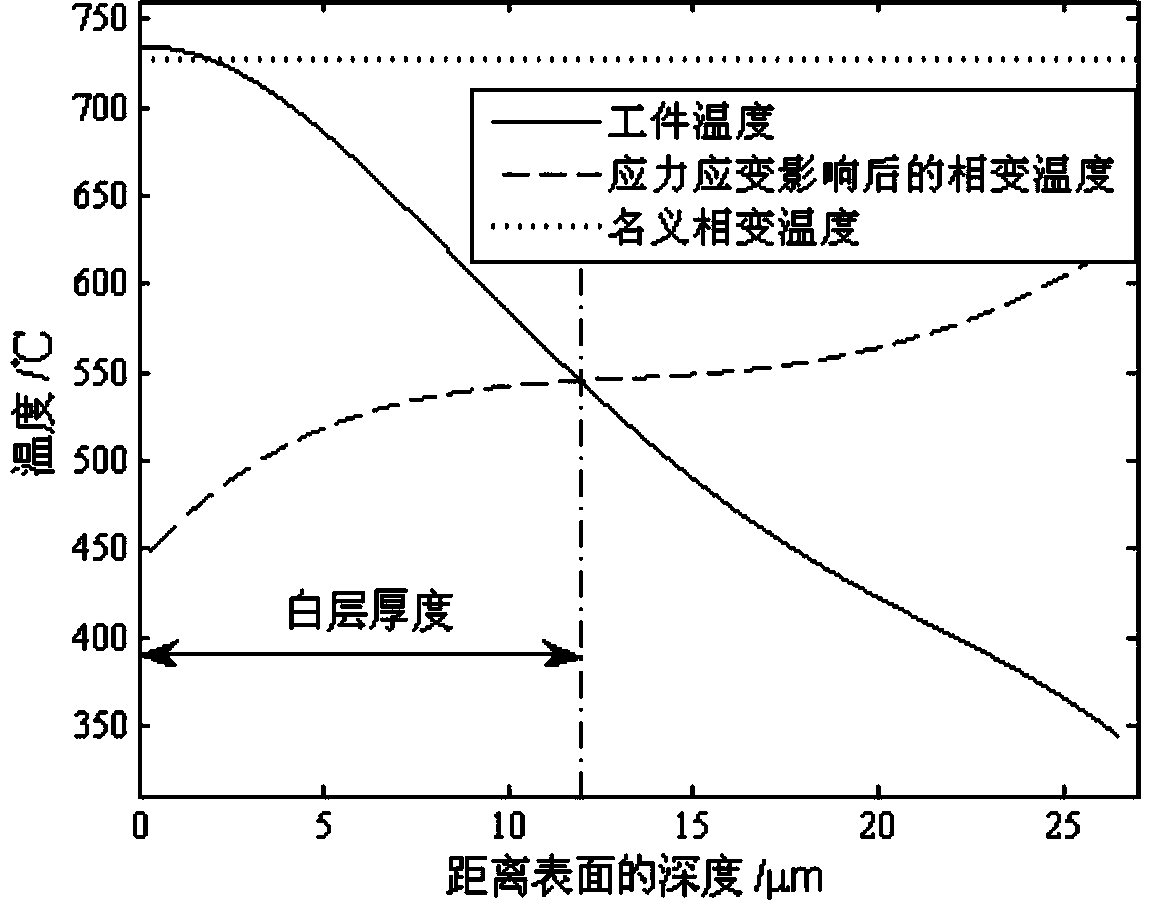

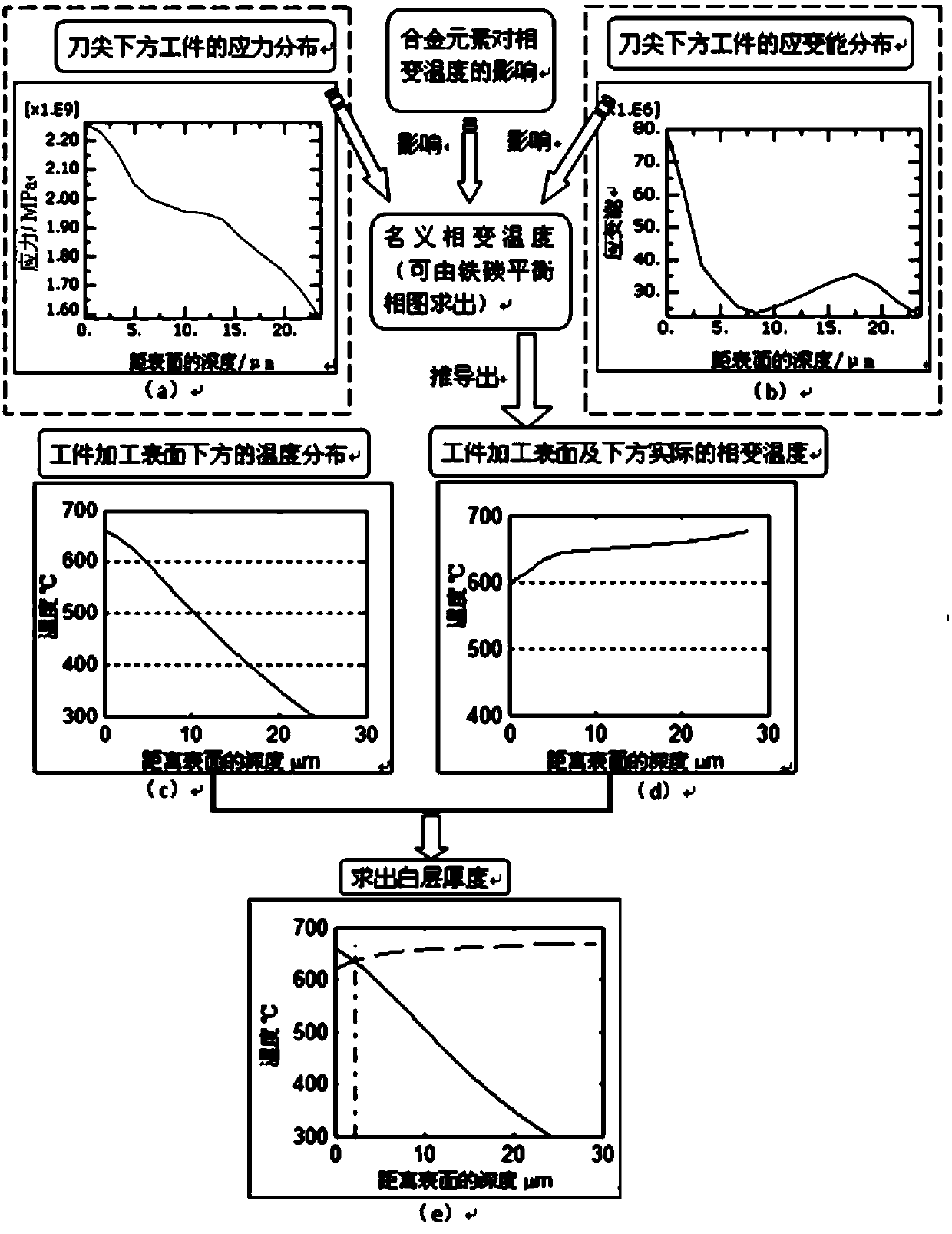

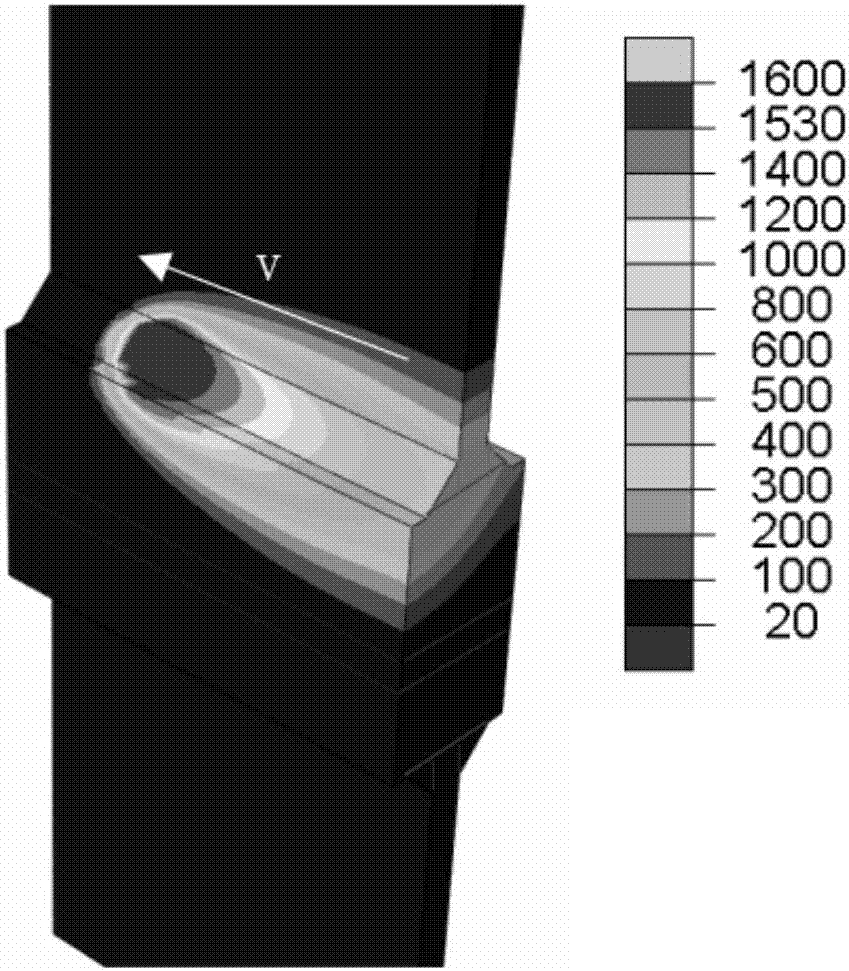

Thermal-mechanical coupling predication method for thickness of white layer on surface of hard tuned workpiece

InactiveCN104050335AThickness PredictionImprove processing efficiencySpecial data processing applicationsElement analysisMachined surface

The invention belongs to the technical field of machining and relates to a thermal-mechanical coupling predication method for the thickness of a white layer on the surface of a hard tuned workpiece. The method includes the following steps that finite element modeling and simulating are performed in the hard tuning process; stress and strain energy data of the machined surface are extracted from a finite element post analysis result, and critical austenite phase change temperature under influences of coupling of stress, strain and alloying elements is calculated; temperature distribution data underneath the machined surface are extracted from the finite element analysis result, and the thickness of the white layer on the surface is predicated according to temperature distribution and the actual critical phase change temperature. A finite element predication model of the thickness of the white layer on the dry hard tuned surface based on the phase change mechanism is provided and not only can predicate the thickness of the phase change white layer on the surface more accurately under the condition that thermal-mechanical coupling factors are considered, but also discloses the internal mechanism of forming the white layer.

Owner:DALIAN UNIV OF TECH

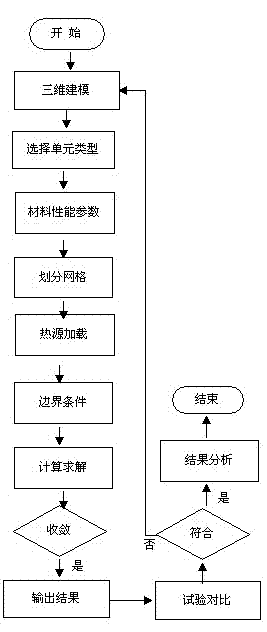

Steel-aluminium transition joint T-shaped bilateral space welding process numerical simulation calculation method

ActiveCN107967376AReduce the maximum temperatureGeometric CADDesign optimisation/simulationEngineeringCorrection method

The invention provides a steel-aluminium transition joint T-shaped bilateral space welding process numerical simulation calculation method, and belongs to the field of welding numerical simulation. The steel-aluminium transition joint T-shaped bilateral space welding process numerical simulation calculation method includes the steps that a three-dimensional or two-dimensional thermal-mechanical coupling calculation model of a steel-aluminium transition joint welding process is established; initial conditions and boundary conditions of the welding model are set; a heat source equation correction method of a T-shaped joint with welding angles is determined; a T-shaped bilateral space welding heat source subprogram is established; a task is submitted and solved, and then pose-processing and analysis are carried out. The steel-aluminium transition joint T-shaped bilateral space welding process numerical simulation calculation method has the advantages of being capable of achieving the purpose that numerical simulation calculation of a temperature field and numerical simulation calculation of a stress field can be conducted synchronously in a three-dimensional or two-dimensional T-shaped joint bilateral space welding process. By establishing a geometric structure of an actual steel-aluminium transition joint and correctly setting a bilateral space welding heat source model with angles, the influences of different welding line energies and bilateral space welding durations on a steel-aluminium interface highest temperature can be predicted, and choices for practical welding process parameters and time intervals of bilateral welding operation are guided.

Owner:CENT IRON & STEEL RES INST +1

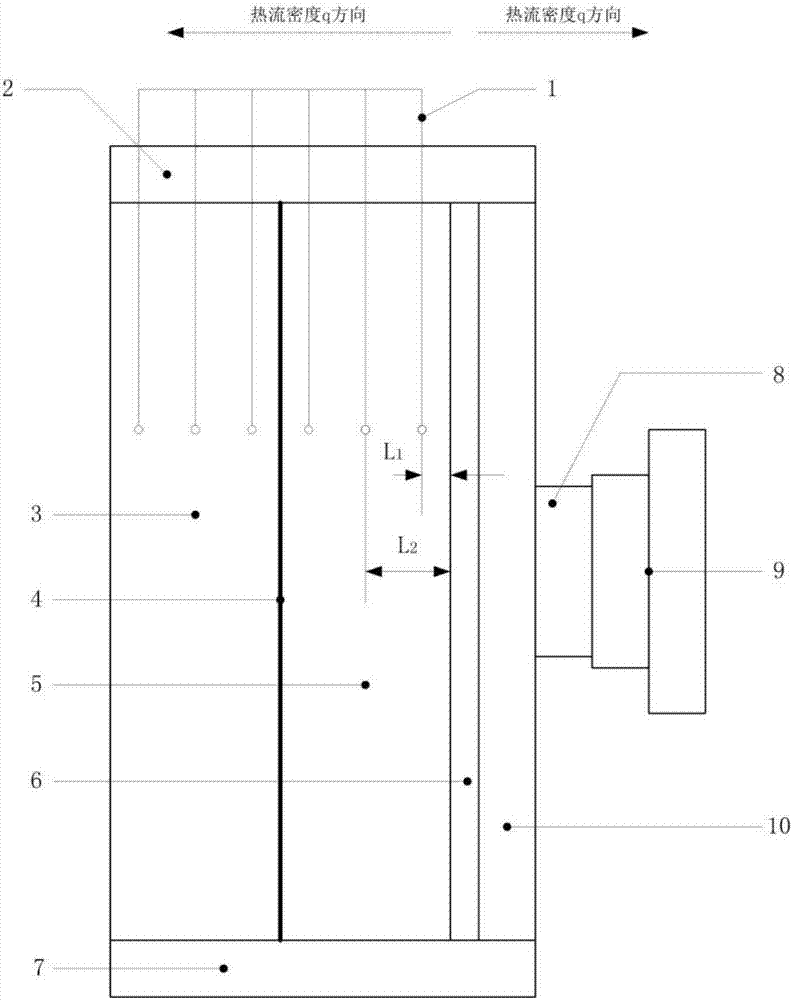

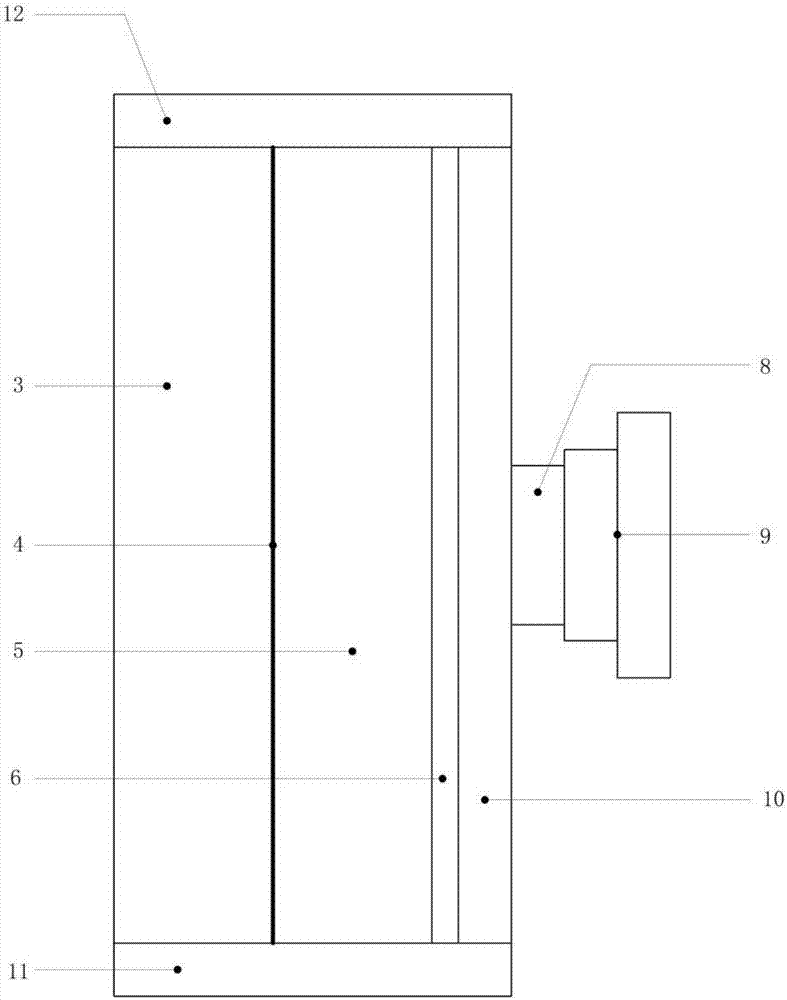

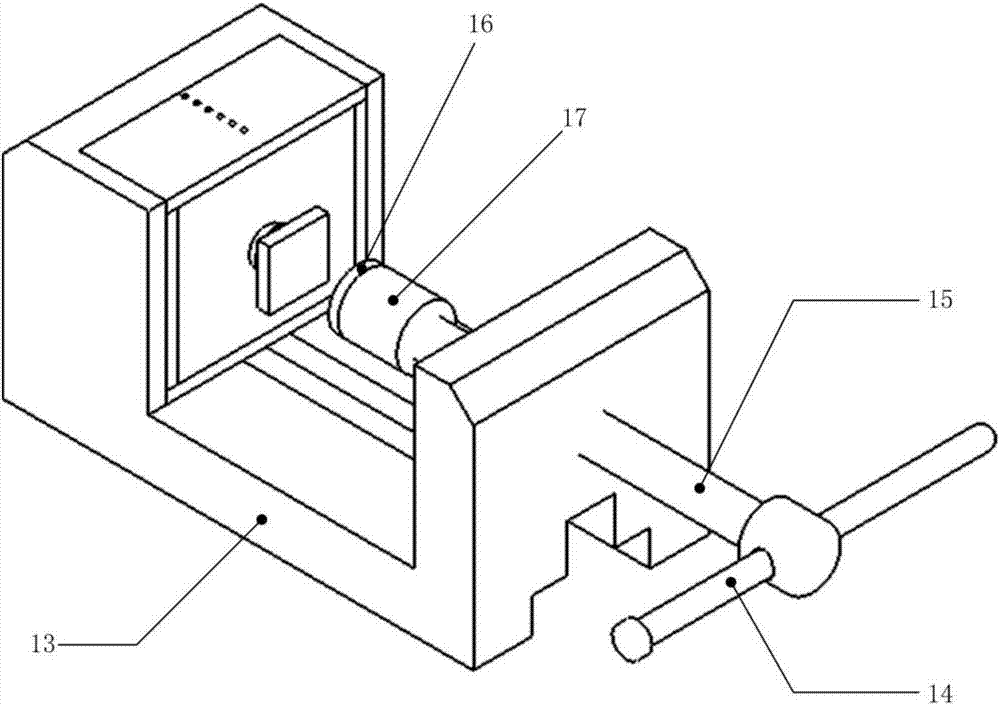

Testing method and device for influence relation of thermal contact resistance of bonding surface by normal load

InactiveCN107490595AEasy to makeMeet the experimental requirementsMaterial heat developmentNormal loadMeasurement device

The invention discloses a testing method and device for an influence relation of thermal contact resistance of a bonding surface by a normal load and belongs to the technical field of thermal conduction and thermal-mechanical coupling tests of solid-state materials. According to the testing method, two rectangular testing parts and one rectangular heating plate are used for creating a one-dimensional stable heat-conducting environment which is used for conducting along the rectangular testing parts and along the X direction. The load, which is borne by load simulation equipment in an operation process, is applied to the other side of the heating plate. Temperature measurement sensors, which are uniformly distributed on the rectangular testing parts, are used for measuring temperature of different radiuses in the X direction; meanwhile, heat insulation devices are arranged at the upper, lower, front and back parts of the testing device, and the measurement of the thermal contact resistance of a bonding surface to be tested in an actual operation process is realized according to transmission distribution of a temperature gradient along the X direction and hot flow density. By adopting the testing method and device, disclosed by the invention, the disadvantages of tests on the thermal contact resistance of the bonding surface in the prior art are overcome; a measurement device is convenient to manufacture and a measured result meets experiment requirements; the testing method and device can be used for the fields including engineering practice, teaching, scientific researches and the like.

Owner:BEIJING UNIV OF TECH

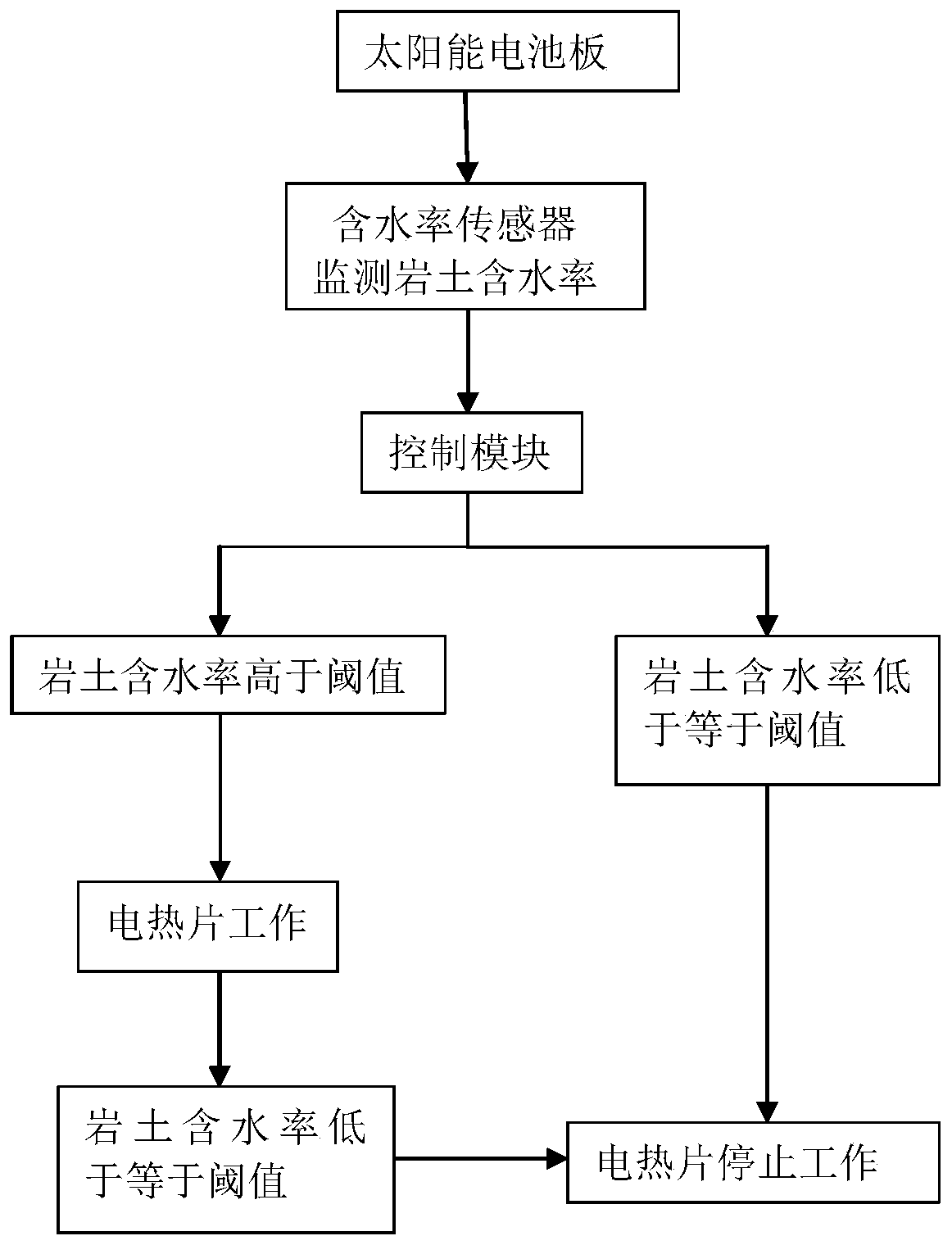

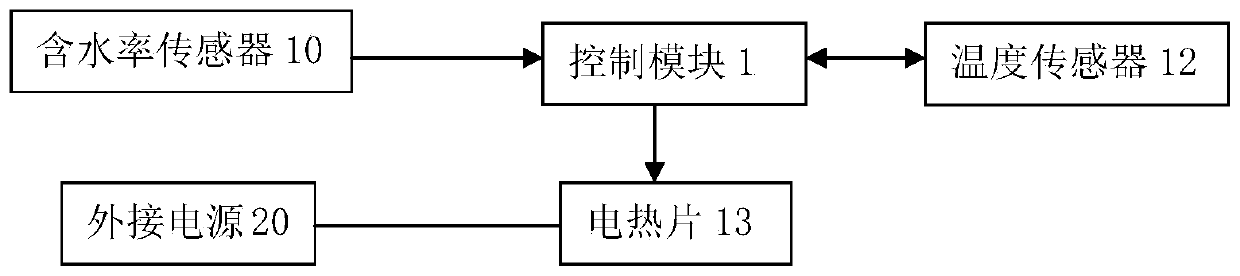

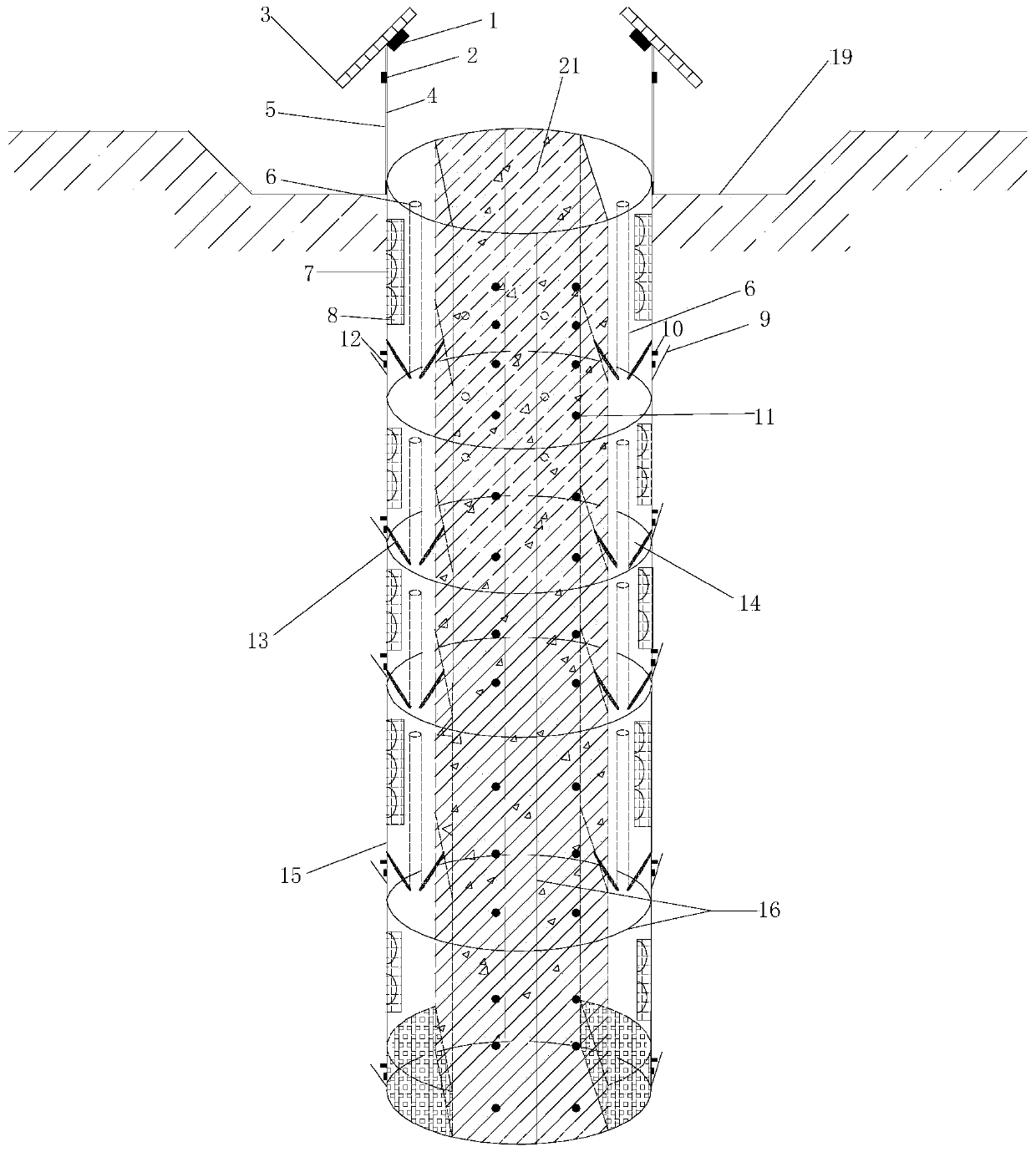

Thermal mechanical coupling slide-resistant pile

ActiveCN111139844AReduce construction proceduresImprove effectivenessHuman health protectionMeasurement devicesWater storageWater vapor

The invention relates to a thermal mechanical coupling slide-resistant pile. The thermal mechanical coupling slide-resistant pile comprises a pile lining and a pile core, wherein the pile lining is formed in a way that a plurality of functional walls are assembled; moisture sensors and temperature sensors are arranged on the outer sides of the functional walls; cavities are formed in the inner sides of the functional walls, electric heating pieces are laid in the cavities, water inlets are formed in the cavities, and geotechnical cloth is laid outside the water inlets; except the bottom end ofthe cavity of the functional wall which is located at the bottom of the pile lining is sealed as a water storage cavity, water vapor overflowing pipes are arranged in the cavities of other functionalwalls, and the bottoms of the cavities are open as exhaust channels; and both the moisture sensors and the temperature sensors are connected with a control module, and the control module is connectedwith the electric heating pieces. According to the thermal mechanical coupling slide-resistant pile, slide resistance is realized, and the functions of water drainage, precise control over water andimprovement of soil nature are integrated. Additionally, retaining walls can be replaced by the functional walls of the thermal mechanical coupling slide-resistant pile, so that the retaining wall construction process is omitted, the landslide control effect is greatly increased, and the investment is reduced.

Owner:CHINA THREE GORGES UNIV

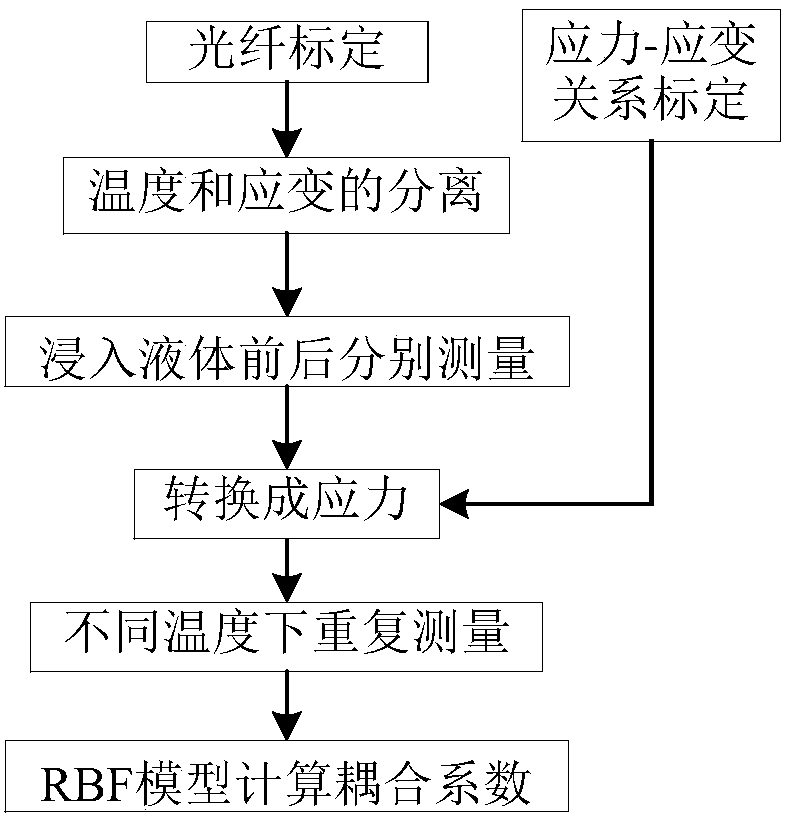

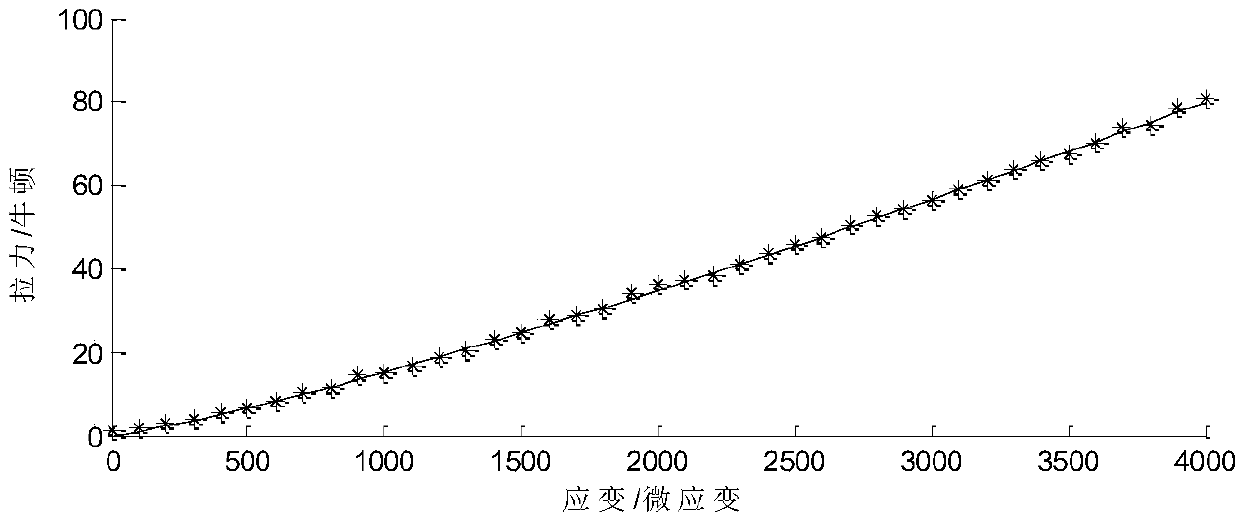

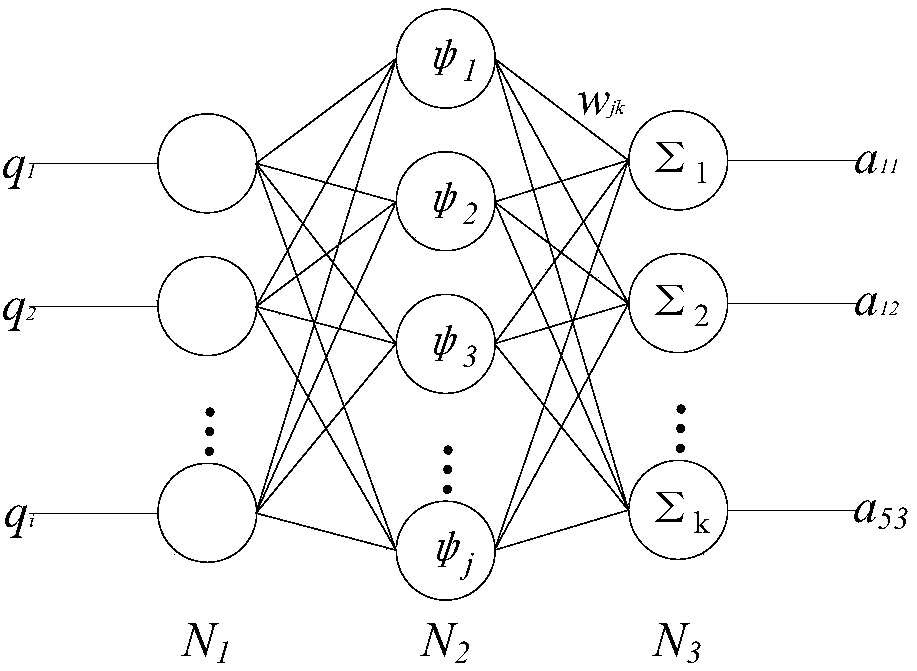

Thermal mechanical coupling decoupling method based on BOTDR (Brillouin Optical Time Domain Reflection) technology

InactiveCN107633136AAdaptableAccurate Stress SolvingNeural architecturesSpecial data processing applicationsTime domainStress measurement

The invention discloses a thermal mechanical coupling decoupling method based on a BOTDR (Brillouin Optical Time Domain Reflection) technology. In engineering application, a thermal mechanical coupling process a mutual influencing process between two physical fields: a stress field and a temperature field, namely, stress deformation is influenced by temperature, and moreover, temperature change isinfluenced by the stress deformation. Due to a thermal mechanical coupling influence, an optical fiber itself changes along with the temperature change, and small change occurs in a strain and stresscorresponding relationship. According to the method, the small change is decoupled, so the strain and stress relationship is relatively accurate. In order to overcome the deficiency resulting from athermal mechanical coupling phenomenon in the prior art, the invention provides the thermal mechanical coupling decoupling method based on the BOTDR technology. The method is consistent with the strain-stress measurement of the BOTDR technology under the temperature change. The method comprises the steps of S1, calibrating the optical fiber; S2, separating a temperature and strain relationship; S3, establishing a strain and stress relationship; and S4, decoupling the thermal mechanical coupling.

Owner:BEIJING UNIV OF POSTS & TELECOMM

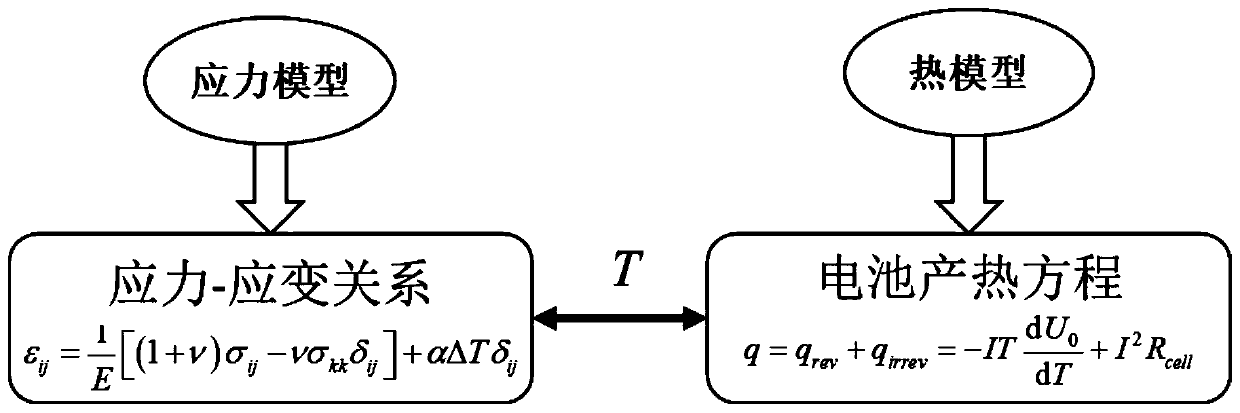

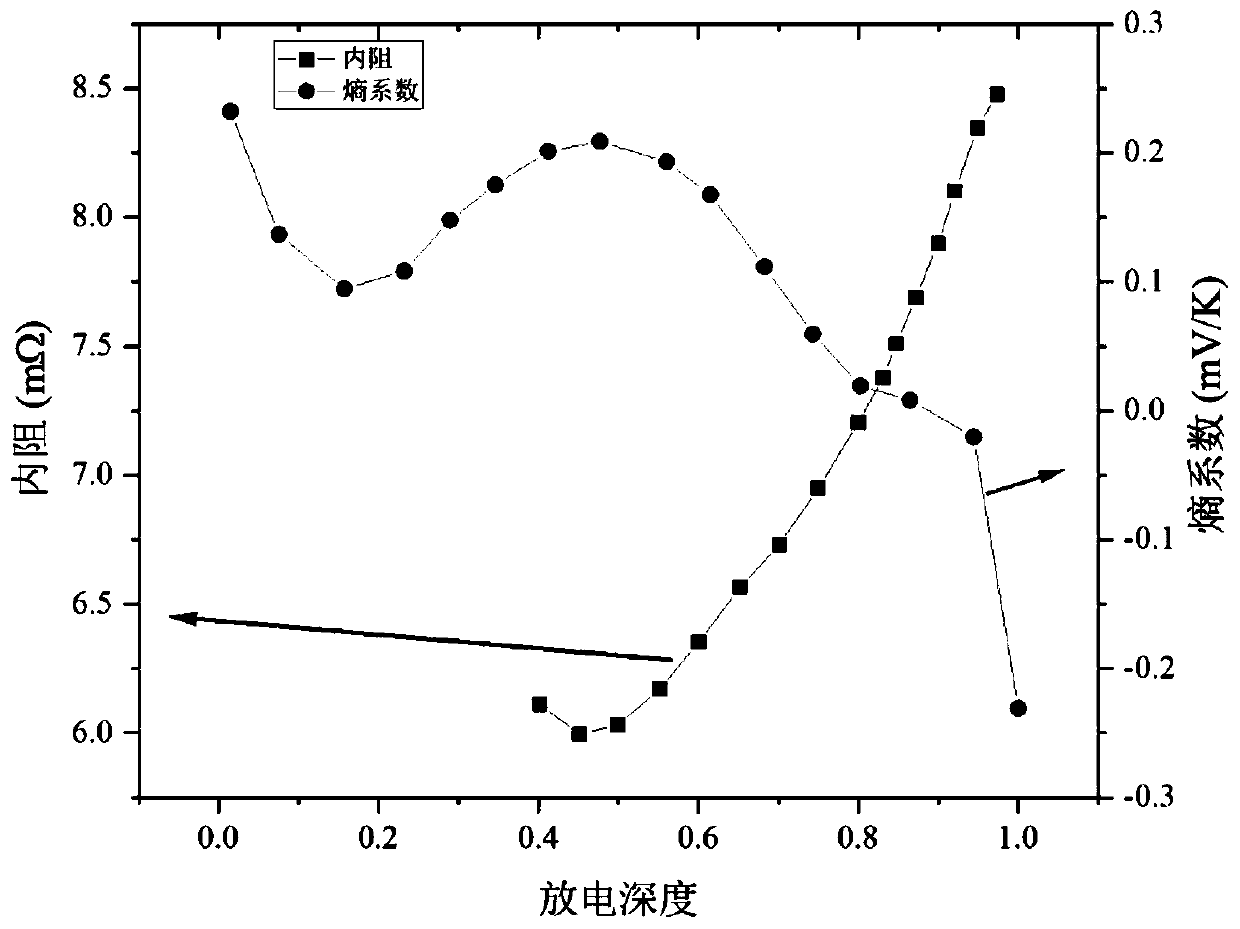

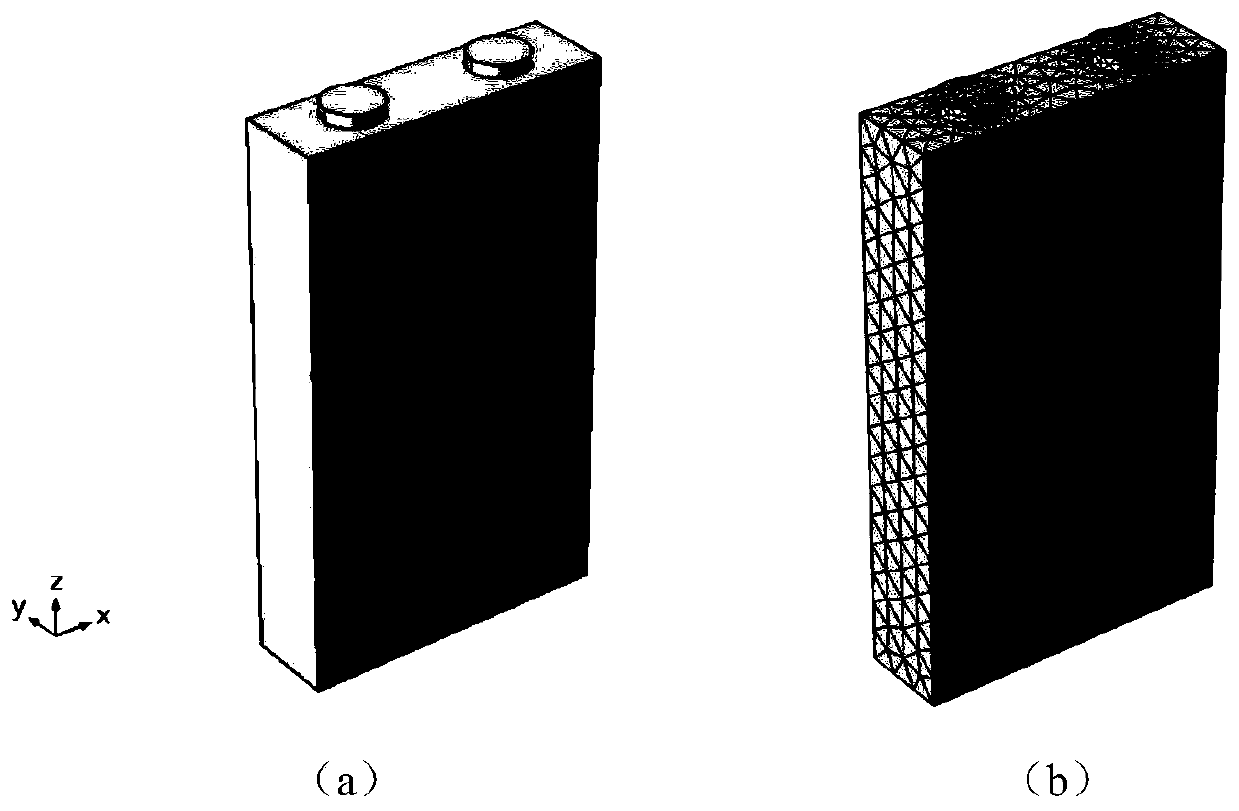

Method for determining thermal stress and temperature in lithium ion battery discharging process based on thermal-mechanical coupling model

ActiveCN110633496AFacilitates analysis of swelling behavioEasy to analyze stressSpecial data processing applicationsMacroscopic scaleThermal expansion

The invention discloses a method for determining thermal stress and temperature in the discharge process of a lithium ion battery based on a thermal-mechanical coupling model, and relates to the fieldof lithium ion battery thermal expansion and stress calculation. The method is used for establishing a thermal expansion model according to the three-dimensional geometrical scale of the lithium ionbattery, and comprises the following specific steps: (1) selecting a single battery cell, and acquiring three-dimensional geometrical parameters and mechanical and thermodynamic initial parameters ofthe single battery cell; (2) establishing a three-dimensional cell scale thermal-mechanical coupling model according to the thermal expansion coefficient, the temperature difference and a coupling mechanism of a stress-strain relationship; (3) measuring the temperature of the battery and the temperature of the tab through experiments, and verifying the effectiveness of the model; and (4) obtainingtemperature distribution of the battery and expansion displacement and stress along x, y and z directions. The method is an expansion model on the macroscopic scale of the battery cell, and can provide a certain guidance basis for the prediction of the expansion behavior and fracture of the battery cell in the charging and discharging process.

Owner:UNIV OF SCI & TECH OF CHINA

A Method for Establishing Lubricating Oil Film Model of Hydrostatic Thrust Bearing After Thermal-Mechanical Coupling Deformation

InactiveCN103246786BAvoid lubrication failureIncrease speedSpecial data processing applicationsThrust bearingThermal deformation

Owner:HARBIN UNIV OF SCI & TECH

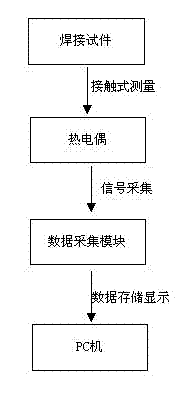

NANMAC-E12-3-K-U thermocouple measurement clamp based on thermal-mechanical coupling during milling

ActiveCN107263141AFlexible angle adjustmentSolve the fact that the actual force cannot be obtained at the same timeMeasurement/indication equipmentsPositioning apparatusThermocoupleMachining process

The invention relates to a thermocouple measurement clamp, in particular to a NANMAC-E12-3-K-U thermocouple measurement clamp based on thermal-mechanical coupling during milling. The invention aims to solve the problem that force data and temperature data cannot be measured simultaneously in a milling machining process in a thermal-mechanical coupling experiment. The NANMAC-E12-3-K-U thermocouple measurement clamp comprises a clamp body, a fixing bolt, a hinge, a force measurer, a pedestal, a supporting seat assembly and a thermocouple, wherein the pedestal is mounted on the force measurer; one end of the lower surface of the clamp body is connected with one end of the upper surface of the pedestal in a rotatable manner through the hinge; the other end of the lower surface of the clamp body is connected with the upper surface of the pedestal through the supporting seat assembly; a cavity is formed inside the clamp body; and the thermocouple is mounted in the cavity through the fixing bolt. The NANMAC-E12-3-K-U thermocouple measurement clamp based on the thermal-mechanical coupling during milling belongs to the field of machining.

Owner:HARBIN UNIV OF SCI & TECH

High temperature performance thermal-mechanical coupling test platform for high temperature heat seal

The invention relates to a high temperature performance thermal-mechanical coupling test platform for a high temperature heat seal. The high temperature performance thermal-mechanical coupling test platform comprises a mechanical testing machine supporting base, a pressing head, an electromagnetic induction coil and a heating body, wherein the supporting base is fixedly mounted on an experimentalplatform of a mechanical testing machine, a base is fixedly connected onto the supporting base, and the heating body is mounted on the base; the electromagnetic induction coil sleeves the heating body, and both ends of the electromagnetic induction coil are connected to high-frequency induction equipment; and a pressing rod of the mechanical testing machine is fixedly connected with the pressing head. The high temperature performance thermal-mechanical coupling test platform improves the mechanical testing machine and combines the mechanical testing machine with the high-frequency induction equipment to build the test platform, adopts induction heating as a heating mode, can provide high temperature rising rate, and is applied to ultra-high temperature thermal environment simulation tests.

Owner:HARBIN INST OF TECH

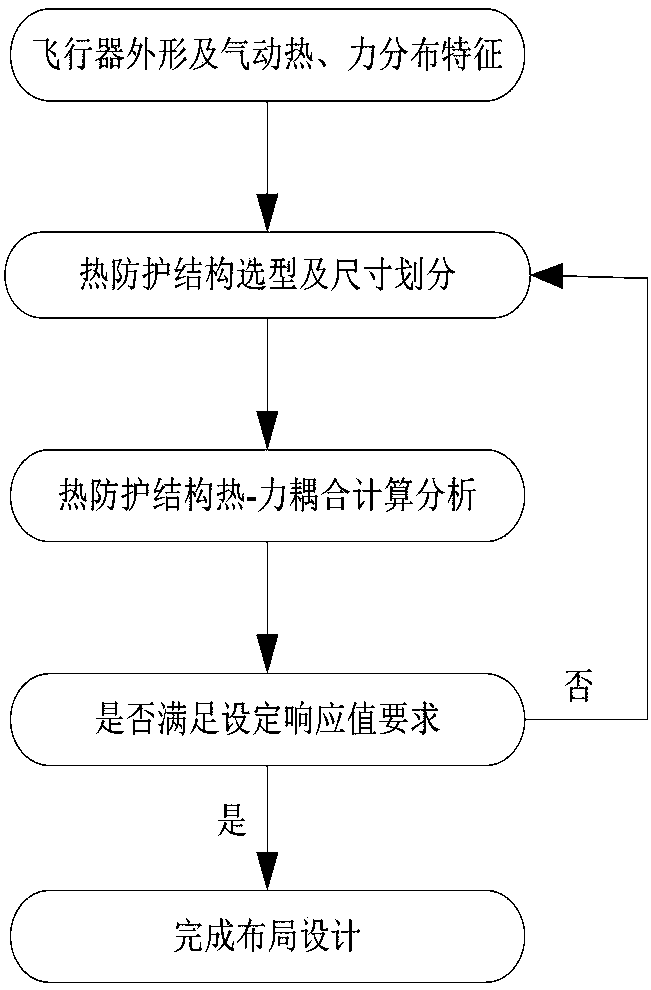

Block partitioning layout method and system for thermal protection structures of complex shape aircraft

ActiveCN108334655AImprove structural strengthImprove performanceGeometric CADDesign optimisation/simulationEngineeringDesign methods

The invention provides a block partitioning layout method for tile-type external thermal protection structures of a complex shape aircraft. According to the method, thermal-mechanical coupling calculation analysis on the thermal protection structures of different sizes is conducted according to the thermal protection structure design and application constraints of the aircraft to obtain the corresponding relationship between thermal protection structure sizes and response, an allowable response value is set by a test means, and the block partitioning layout design of the thermal protection structures of different parts is finally completed. According to the method and the system, the most critical layout application problem of the tile-type thermal protection structures is solved, and an important technical means is provided for a novel thermal protection structure from a principle sample piece to integrated application.

Owner:BEIJING AEROSPACE TECH INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com