Fatigue test method of cylinder cover simulating test specimen

A technique for fatigue testing and simulation parts, applied in the field of fatigue testing, which can solve the problems of limited research objects, standard parts, fatigue damage, and high requirements for experimental equipment, achieve high accuracy and pertinence, facilitate clamping and measurement, and reduce test costs. cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

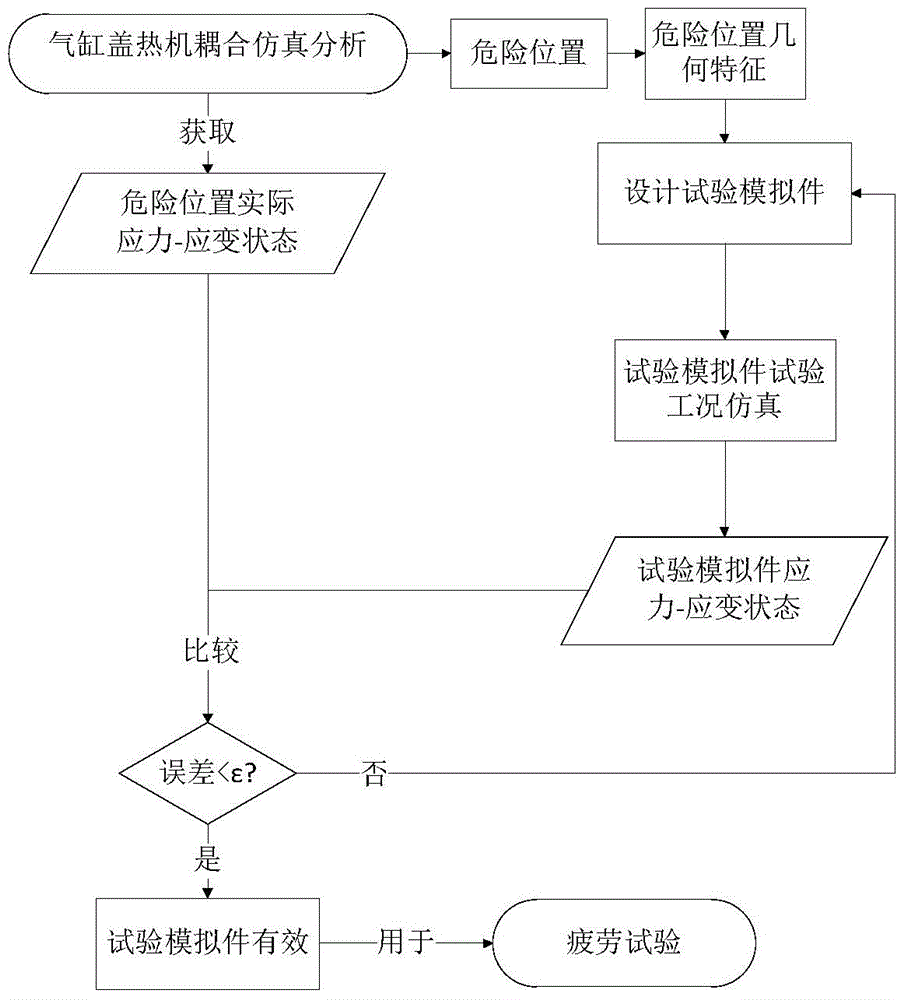

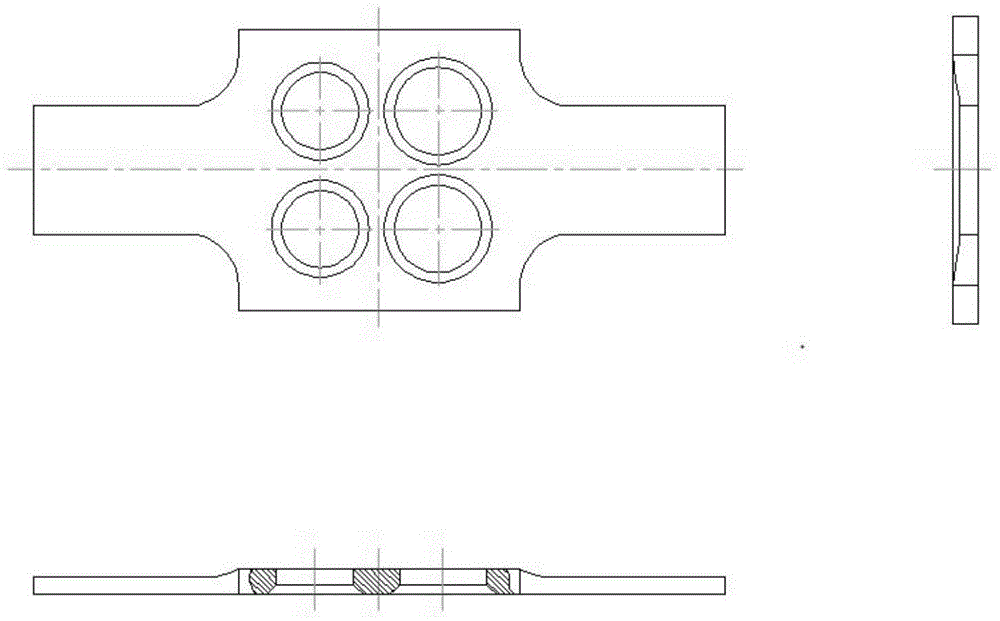

[0039] Use simulation software (such as: Fire, ANSYS software, etc.) to carry out two-phase fluid-solid coupling simulation, determine the temperature field of the cylinder head structure, and determine the high temperature dangerous position. Use simulation software (such as: ANSYS, ABAQUS software, etc.) to carry out the stress-strain analysis of the cylinder head, determine the low-cycle fatigue dangerous position of the cylinder head, and the magnitude and direction of each stress-strain component at the dangerous position. Preliminary determination of the shape of the simulated part of the dangerous position of the cylinder head and the size of the test load. In order to make the simulated part have a strong equivalence, the simulation software is further used to perform finite element simulation on the simulated part. Through a certain iterative process, the actual dangerous position of the cylinder head is compared with the simulation. The stress-strain conditions at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com