Brake squeal prediction method of considering thermal-mechanical coupling effect

A technology of thermal-mechanical coupling and prediction method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of complex squeal effects, braking squeal effects, and no clear relationship between temperature and squeal. To achieve the effect of ensuring accuracy, improving accuracy and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

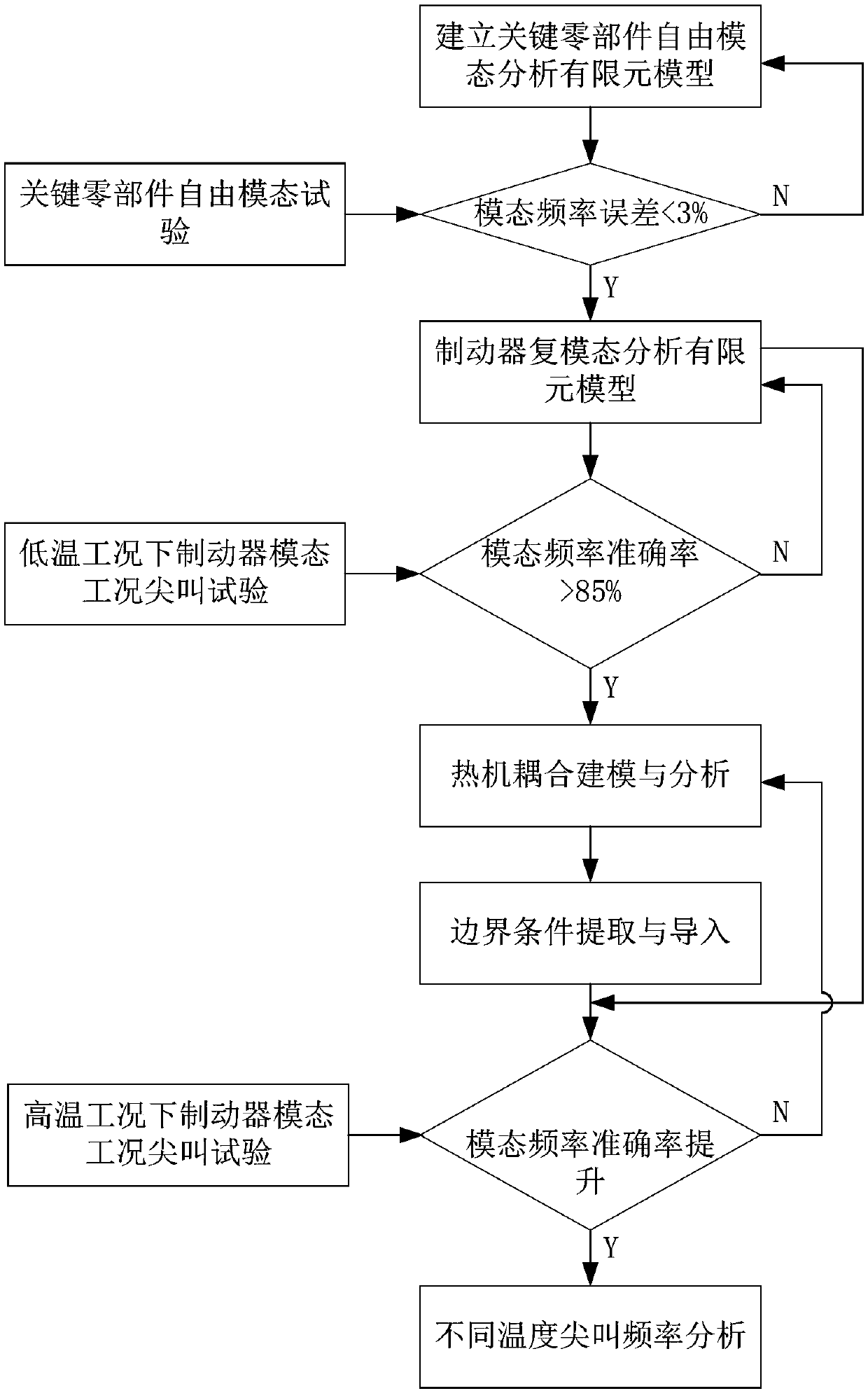

[0045] A brake squeal analysis method considering the thermal-mechanical coupling effect, the overall process is as follows figure 1 shown, including the following steps:

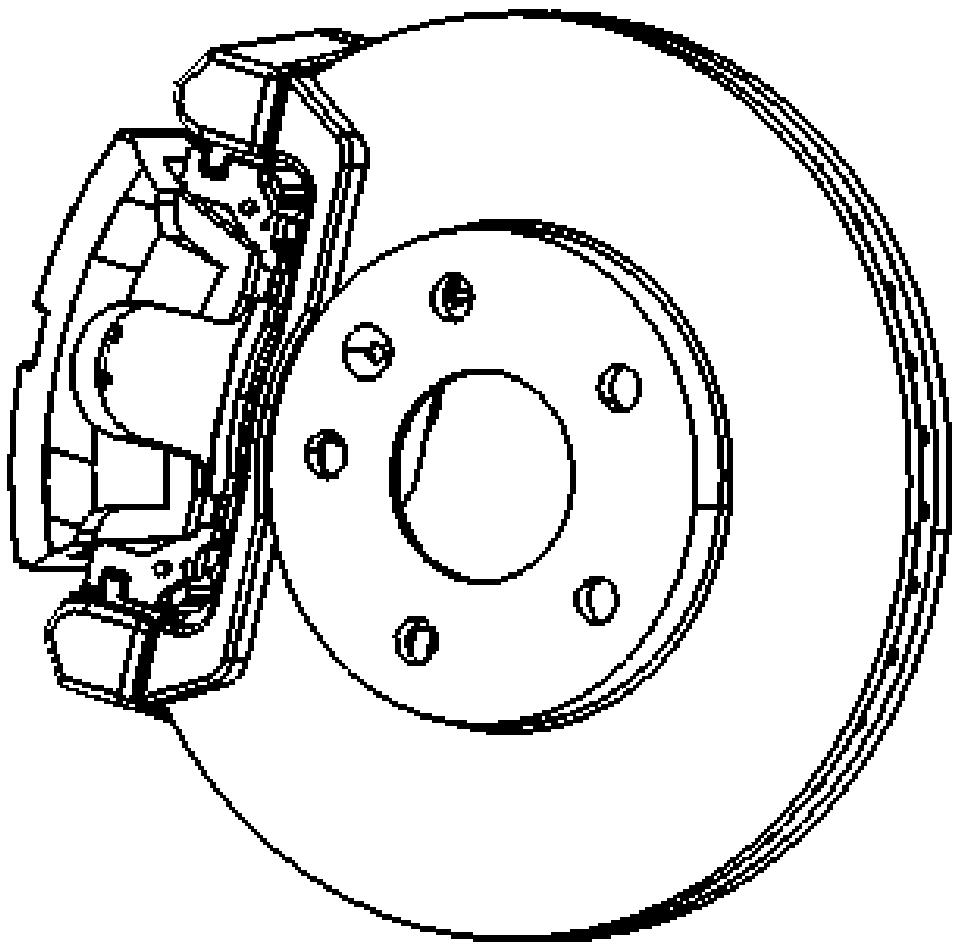

[0046] Step 1: If figure 2 As shown, the assembly model of the ventilated disc brake system is established by using the 3D modeling software. Clamp refers to the composition of rigid surfaces. And ignore the small structures such as the grinding relief groove on the surface of the brake disc and the back plate of the brake block, the small boss of the hub and the chamfer;

[0047] Step 2: Perform a free modal test. In order to extract the out-of-plane modal parameters of the brake disc, the method of single-point excitation and 14-point pickup test in the Y direction is adopted. The layout of the pickup sensors is 14 uniformly distributed unidirectional acceleration sensors in the circumferential direction. The brake disc under test adopts a rubber rope suspension installation method, and the suspensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com