Thermal mechanical coupling slide-resistant pile

A heat-mechanical coupling and anti-sliding pile technology, applied in sheet pile walls, electric heating devices, excavation, etc., can solve the problems of increasing construction costs, weakening anti-sliding ability, no anti-sliding, drainage, and improvement of sliding zone soil, etc., to achieve Effects of improving efficiency, subtracting construction procedures, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

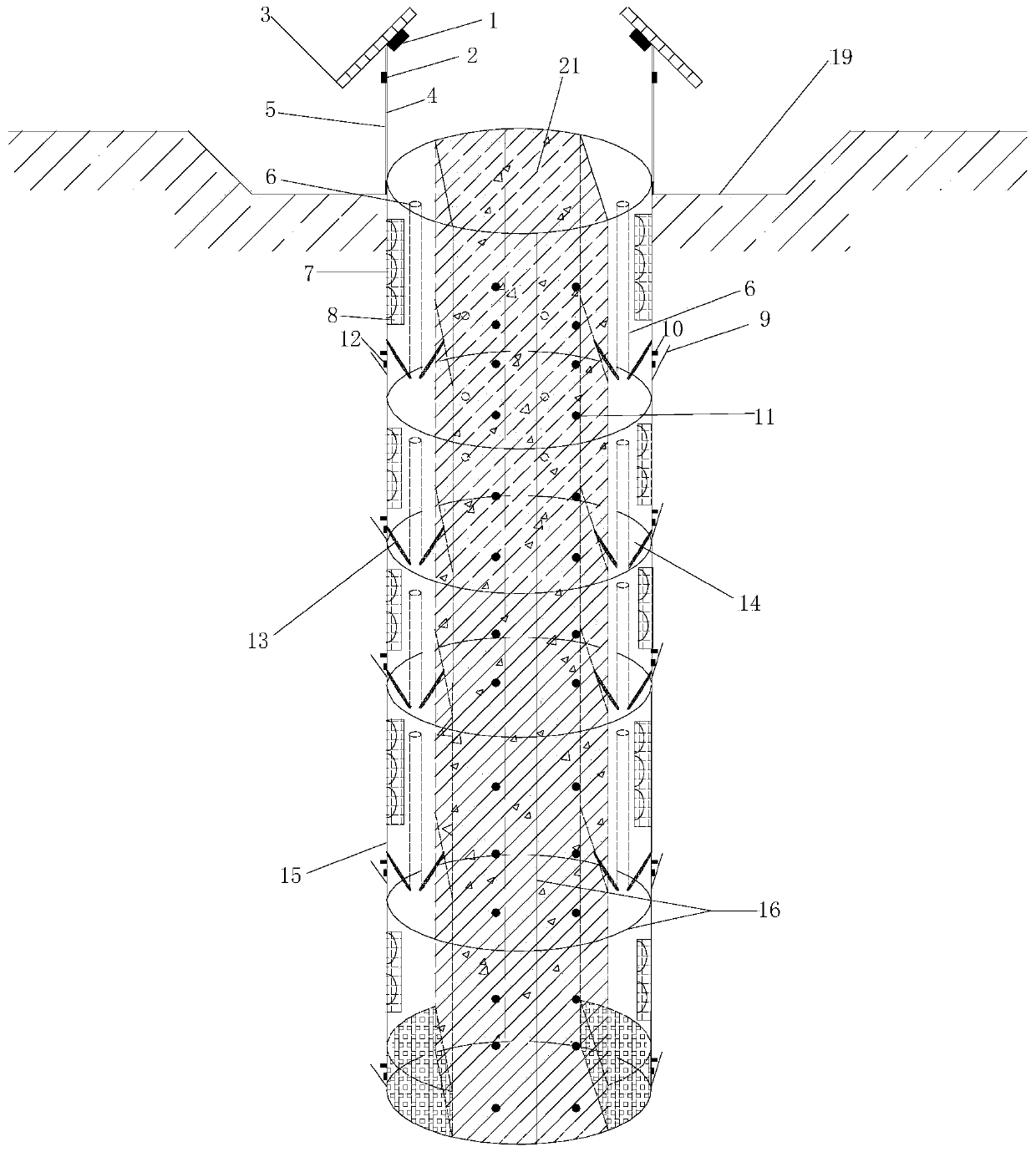

[0039] The pile wall is composed of functional walls that are placed in the pile holes and are spliced sequentially from top to bottom, left and right.

[0040] The functional wall is installed in sections: dig holes to the design distance, install the functional walls opposite to each other on the left and right, drive steel bars through the installation hole 11 to the soil outside the wall to fix the functional wall. Repeat this to complete the splicing and installation of the functional wall of the lower section.

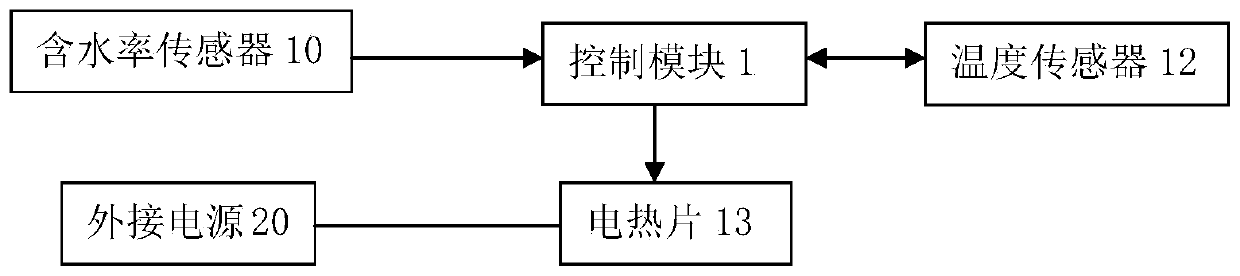

[0041] Set up the left and right solar panels, install the control module 1 respectively, connect the circuit, turn on the master control switch 2, and the functional wall starts to work with electricity.

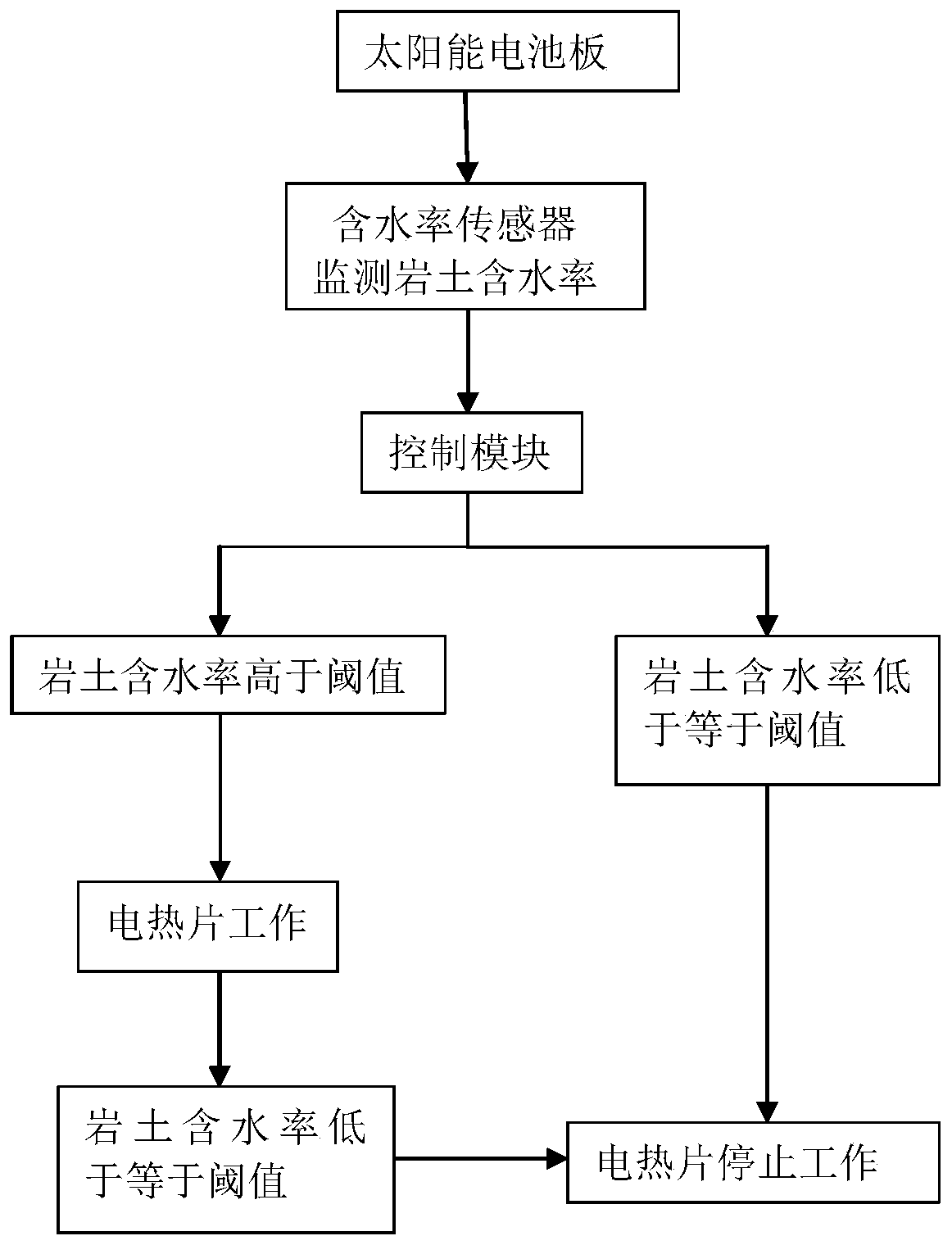

[0042] Connect the external power supply 20, through the control module 1, open the functional wall working circuit of the sliding belt section, heat the heating plate 13 to the temperature of the sliding belt soil denaturation, and keep it until the sliding...

Embodiment 2

[0047] The pile wall is formed by splicing the functional wall outside the pile hole. The lower part of the functional wall located at the bottom of the pile wall is a tapered head 18, and the outside of the pile hole of the pile wall is integrally driven into the pile hole.

[0048] Set up the left and right solar panels, and install the control module 1 respectively, connect the circuit, turn on the master control switch 2, and the functional wall starts to work.

[0049] Connect the external power supply 20, open the functional wall working circuit of the sliding belt section through the control module 1, heat the heating plate 13 to the temperature of the sliding belt soil denaturation, and keep it until the sliding belt soil denatures, realizing the function of soil denaturation.

[0050] The pile core construction shall be set as reinforced concrete, backfill soil, grouting, I-beam, etc. according to project requirements.

[0051] The construction of thermal coupling ant...

Embodiment 3

[0054] The outer steel mold of the pile core is integrally formed, and the embedded joints are preset on both sides of the outer steel mold of the pile core; the functional wall removes the connecting part of the outer mold of the pile core in the middle of the outer wall of the chamber 14, and replaces the embedded edge, and the functional wall with the embedded edge Embedding the pile core outer steel form into the embedding joint sequentially, and forming a whole with the pile core outer steel form, driving into the pile hole, such as Figure 9 shown. In this way, the integrity of the steel mold outside the pile core is also guaranteed, and the shear performance of the steel pipe is fully utilized.

[0055] The pile core construction shall be set as reinforced concrete, backfill soil, grouting, I-beam, etc. according to project requirements.

[0056] The construction of thermal coupling anti-slide pile is completed, and the anti-slide function is realized.

[0057] The so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com